Lubricating oil oxidation stability additive composition and preparation method thereof

A technology of oxidation stability and composition, which is applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the problems such as unsatisfactory oxidation stability, achieve the effect of improving oxidation stability, excellent effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0029] Examples 1-6 The additive composition of the present invention was prepared and its main properties were measured accordingly. Add alkyl diphenylamine (component I) and ester-type shielding phenol (component II) into the blending container in different proportions, heat and stir under normal pressure, the blending conditions and the properties of the obtained product are shown in Table 1.

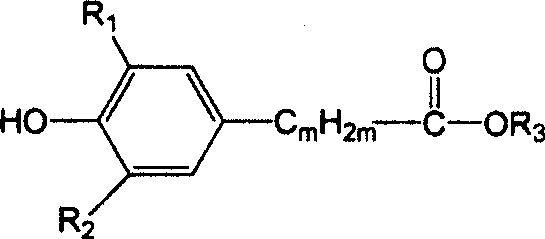

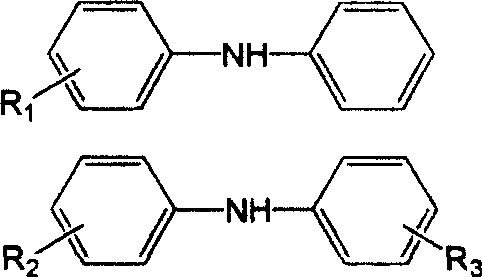

[0030] Among them, T534 is an alkyl diphenylamine antioxidant product produced by Beijing Sanlian Fine Chemical Co., Ltd.; L57 is produced by CIBA Fine Chemical. Both T534 and L57 are mixtures of two alkyl diphenylamines represented by the following formula:

[0031]

[0032] where R 1 , R 2 and R 3 independently selected from C 4 or C 8 of alkyl.

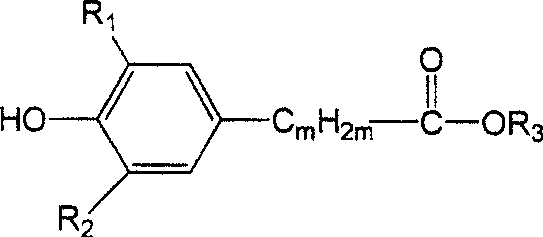

[0033] LZ5150A is produced by LUBRIZOL.CO, and its structure is shown in the following formula:

[0034]

[0035] where R 1 , R 2 for the same C 9 branched chain alkyl.

[0036] T512 is an ester-type shielded phenol antio...

Embodiment 7

[0042] The rotary oxygen bomb test is a common method for rapid screening and determination of the oxidation stability of engine oils and industrial lubricating oils. In this example, the rotating oxygen bomb test ASTM D2272 method is used to evaluate the anti-oxidation effect of lubricating oil. The test instrument consists of a pressure bomb and an oil bath, the pressure bomb rotates 30° with the horizontal plane, and the oil bath has a constant temperature of 150°C. Put 50 grams of test oil, 5 grams of water and copper ring catalyst into the glass together, oxygenate 620kPa (90psi) at room temperature, put the oxygen bomb into the oil bath, the oxygen pressure rises rapidly and remains constant, and the oxygen pressure drops to 175kPa (25psi) time, as the oil sample oxidation induction period. The oil used in the test was 150SN base oil produced by PetroChina Dalian Petrochemical Company. The results are shown in Table 2.

[0043] Table 2

[0044]

[0045] As ...

Embodiment 8

[0047] The Procedure IIIE test method is an engine test method for evaluating the resistance of internal combustion engine oils to high-temperature oxidation, high-temperature sludge and varnish formation tendency, and anti-wear properties. This method is one of several test methods for evaluating the performance of SG, SH, SJ, GF-1, GF-2 gasoline engine oils.

[0048]This embodiment is a high-temperature oxidation test of program III E engine evaluation SH grade gasoline engine oil. The engine is a Buick 3.8L V-6; the 10W / 40 SH grade gasoline engine oil developed by the Academy of Petrochemical Sciences is used; the test oil temperature is 149°C; the total dosage is 10.8% by weight; the phosphorus content is 0.12% by weight, and the formula is implemented using the present invention The additive composition in Example 3 was used in an amount of 0.8% by weight. The test runs continuously for 64 hours under the test conditions specified in the method, and oil samples are colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com