Silicon fiber Ti-gold no-burning flexible joint

A low-alloy, submerged arc welding technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the difficulty of welding technology, limit multi-wire submerged arc welding, joint mechanical properties and operational weldability. Taking into account and other issues, to achieve the effect of being conducive to stable arc welding, reducing the probability of hot cracks, and improving weld strength and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

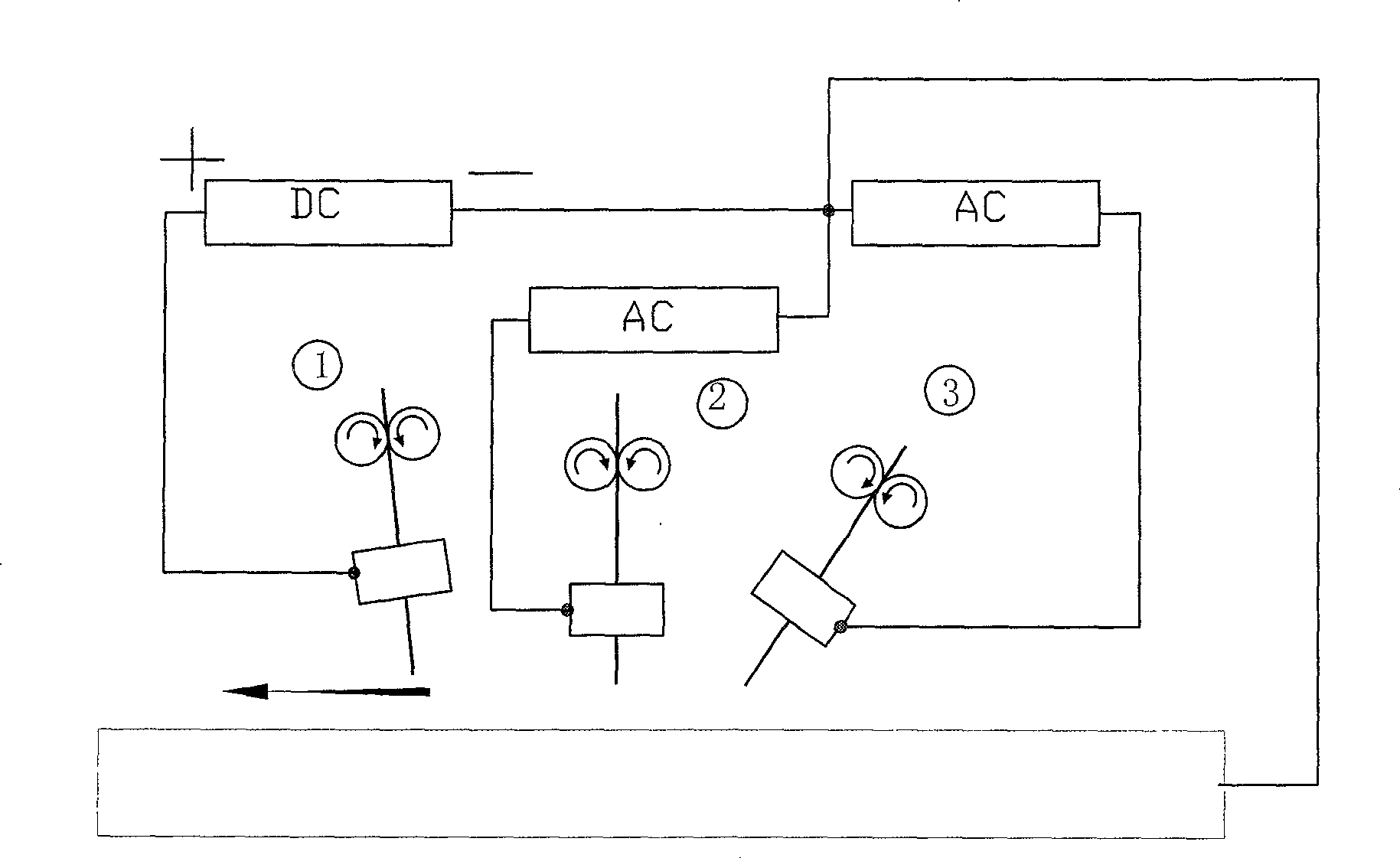

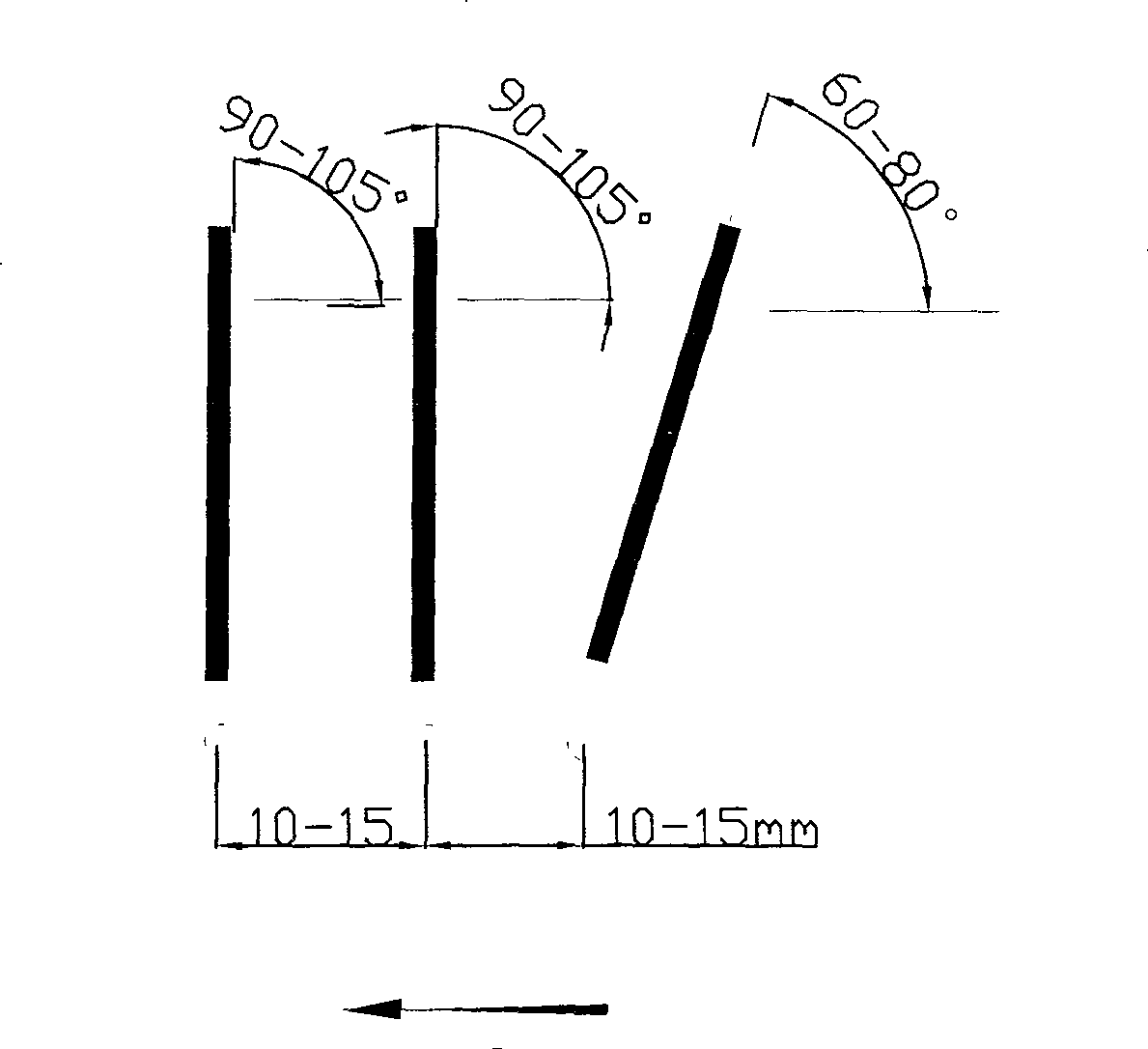

[0016] For the welding of the bottom layer of the thick plate, consider that the welding voltage should match the welding current and welding speed, pay attention to the influence of the welding specification of the auxiliary wire on the weld formation and penetration depth, and use a current (650-700A) and a slightly lower voltage , Welding at a slightly slower welding speed (50-60cm / min) to prevent the weld bead from being too thin and too concave to crack; the weld bead other than the bottom layer is to be welded in multiple layers, and the welding current (650-800A) and voltage are slightly higher , Faster welding speed (55-75cm / min) welding, the surface bead is welded with a smaller current or single or double wire welding, so as to ensure the overall performance of the weld and good appearance.

[0017] For weld bead welding close to the base metal side (especially with a right-angle bevel), consider the influence of the weld metal fusion ratio on the weld performance, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com