Optical fibre grating sensor based on Bourdon tube as energy changer and method thereof

A fiber grating and sensor technology, applied in the field of sensors, can solve the problems of increased failure rate of strain gauges and electrical signal amplification systems, inability to realize real-time separation and detection of pressure and temperature, immature processing technology and modular design, etc., to improve Environmental adaptability and application fields, high reliability, simple modular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

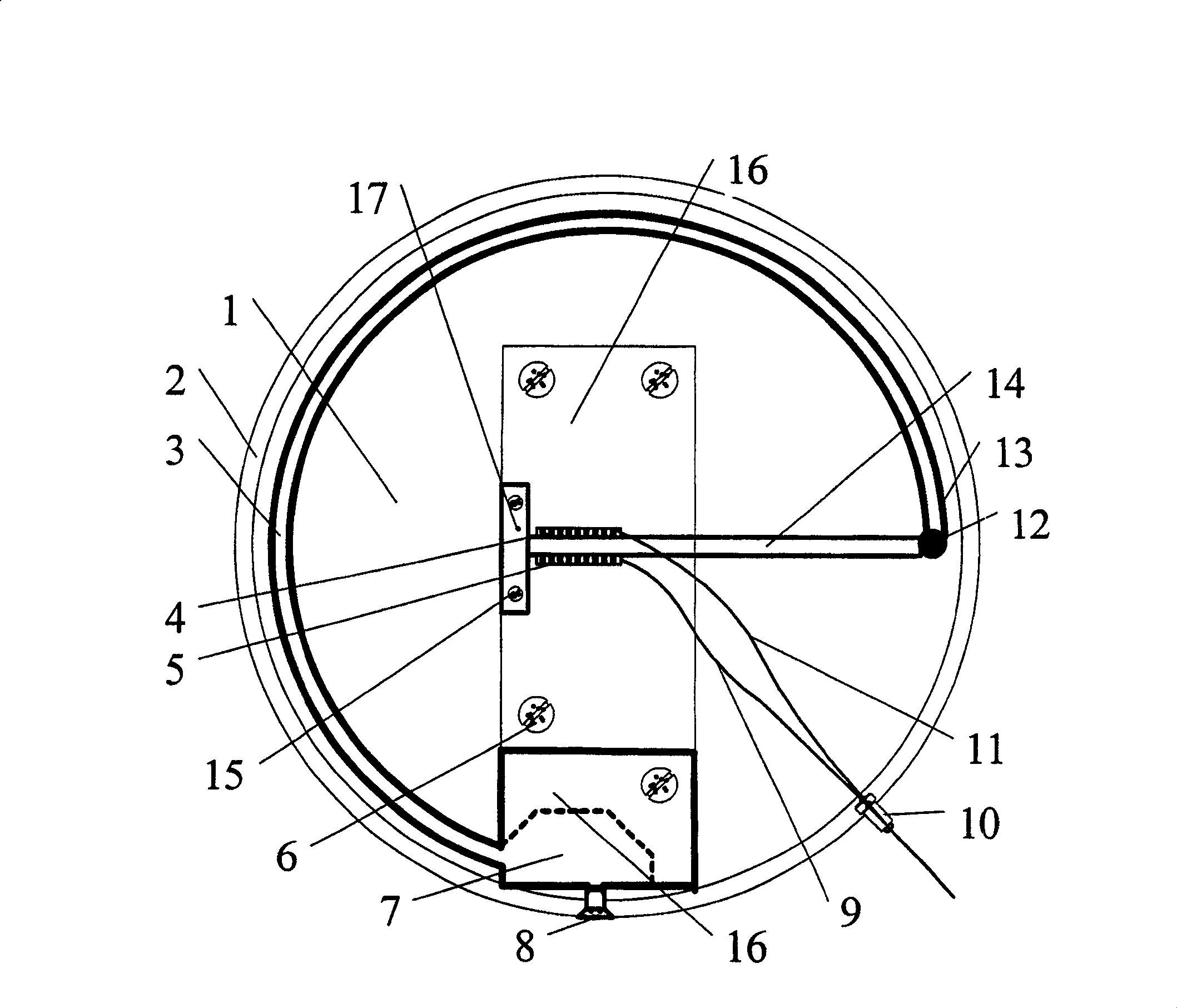

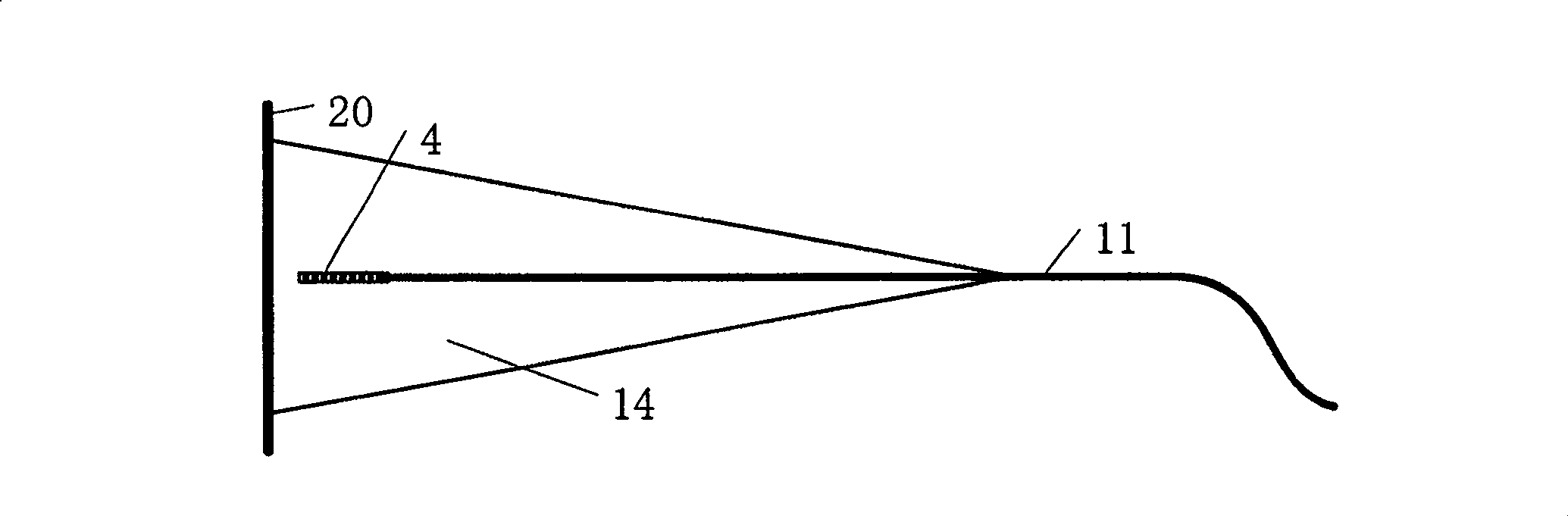

[0020] figure 1 It is a structural schematic diagram of the fiber grating sensor of the present invention. The sensor mainly includes a Bourdon tube (also called spring tube) pressure transducer 3, and the transducer (ie Bourdon tube) 3 includes a first installation base 16 containing a pressure guide hole 7 and a closed free end 13, The first installation base 16 is fixed on the lower base plate 1 by several screws 6, the free end 13 is fixed on the point 12 with the fiber grating cantilever beam 14 by welding or bonding, and the pressure guide nozzle 8 is connected with the pressure guide hole 7 , to guide the external pressure into the Bourdon tube 3; the fiber grating cantilever beam 14 is fixed on the second installation base 17 by fastening screws 15, and the two fiber gratings 4 and 5 with the same performance and with pigtails 9 and 11 They are past...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com