Combined type flow guide polar plate suitable for normal pressure or low pressure fuel cell

A fuel cell and bipolar plate technology, applied to fuel cell components, fuel cells, battery electrodes, etc., can solve problems such as reduced safety, negative values, electrode breakdown, etc., to reduce flow resistance and flow resistance Large, not easy to block the effect of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

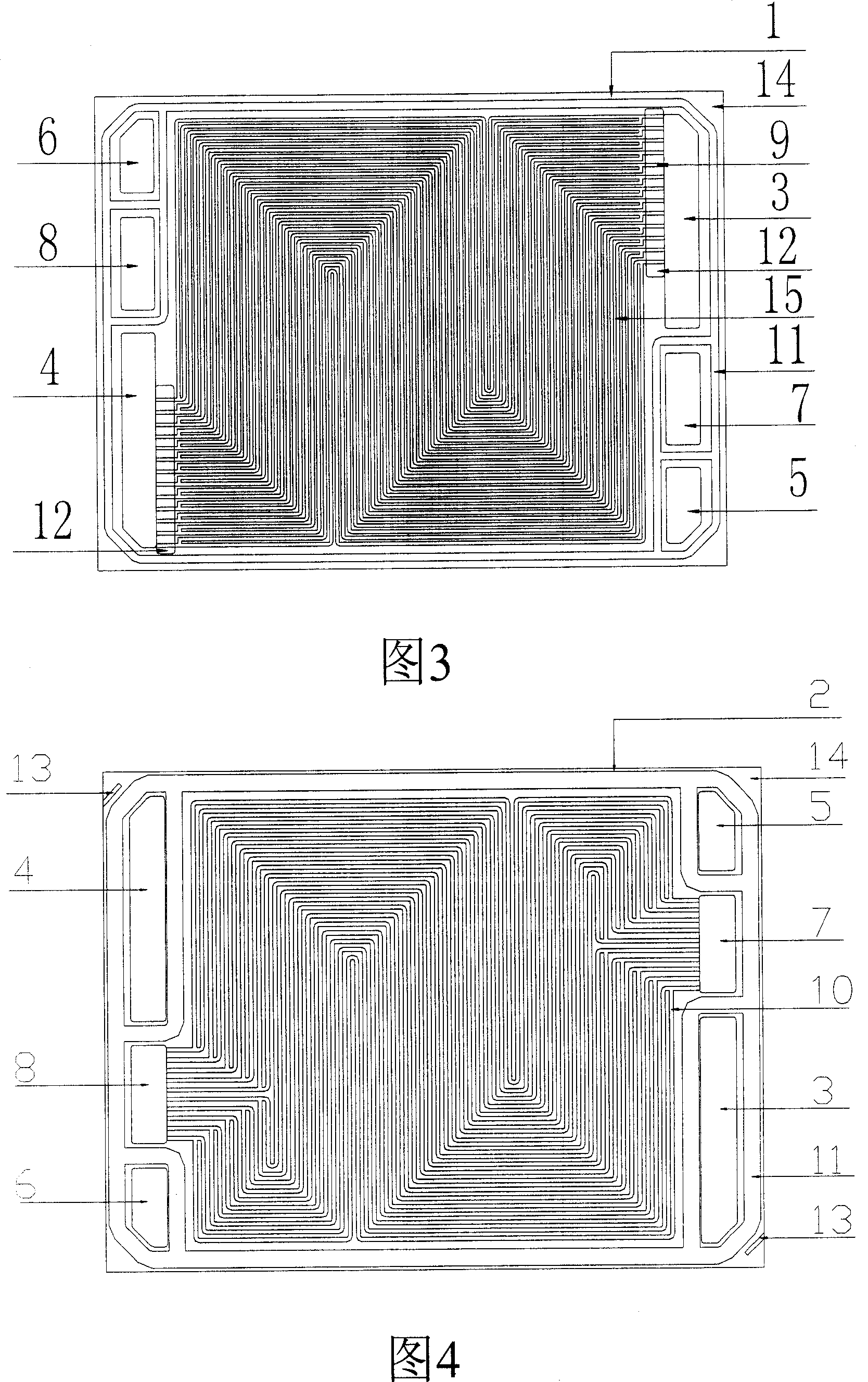

[0040] Such as figure 2 ,Figure 4, Figure 5 As shown, the combined flow guide bipolar plate suitable for atmospheric pressure fuel cells has a size of 150×200×1.5mm. The flow guide bipolar plate is that the air guide plate 1 is opposite to the cooling fluid plate 2 and guides the flow of hydrogen The plate 16 is a rectangular flow-guiding bipolar plate that is integrated, and the flow-guiding bipolar plate includes an air inlet main hole 3, an air outlet main hole 4, a hydrogen inlet main hole 5, a hydrogen outlet main hole 6, and a cooling fluid inlet main hole 7. Cooling fluid outlet mainstream holes 8, each fluid inlet and outlet mainstream holes are arranged at the two ends of the rectangular diversion bipolar plate, the air inlet and outlet mainstream holes of the air deflector 1 are provided with a plurality of air Launder 9, a plurality of cooling fluid launders 10 are arranged between the cooling fluid inlet and outlet main holes of the cooling fluid plate 2, and a ...

Embodiment 2

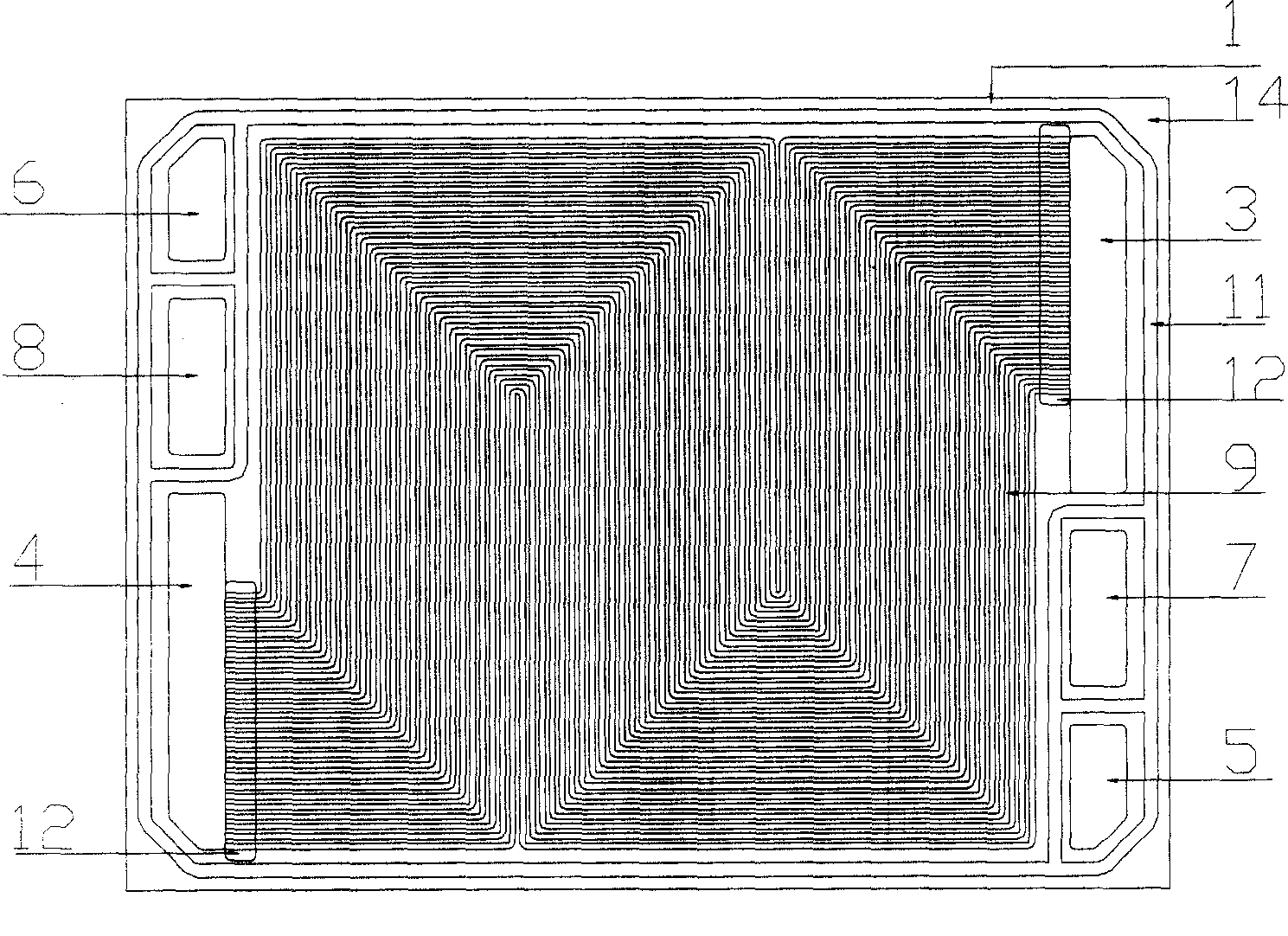

[0050] Figure 3, Figure 4, Figure 5 As shown, the combined flow guide bipolar plate suitable for atmospheric pressure fuel cells has a size of 150×200×1.5mm. The flow guide bipolar plate is that the air guide plate 1 is opposite to the cooling fluid plate 2 and guides the flow of hydrogen The plate 16 is a rectangular flow-guiding bipolar plate that is integrated, and the flow-guiding bipolar plate includes an air inlet main hole 3, an air outlet main hole 4, a hydrogen inlet main hole 5, a hydrogen outlet main hole 6, and a cooling fluid inlet main hole 7. Cooling fluid outlet mainstream holes 8, each fluid inlet and outlet mainstream holes are arranged at the two ends of the rectangular diversion bipolar plate, the air inlet and outlet mainstream holes of the air deflector 1 are provided with a plurality of air Launder 9, a plurality of cooling fluid launders 10 are arranged between the cooling fluid inlet and outlet main holes of the cooling fluid plate 2, and a plurality ...

Embodiment 3

[0055] What is used in the fuel cell stack in Example 1 is a fuel cell air deflector plate suitable for normal-pressure air operation, with a size of 150×200×1.5mm. This embodiment 3 is a kind of fuel cell that is suitable for low-pressure air operation. The fuel cell air guide plate has a size of 150×200×1.5mm, and other designs are the same as those in Example 1, the difference is: air flow groove depth×groove width=0.3×0.8mm, the main flow groove is the same as the branch flow The number of grooves is 20, and the flow resistance encountered by air entering from the inlet of the guide plate is larger than that in Example 1, so the operating pressure of the air is about 0.5 atmospheric pressure (relative pressure), and other cooling fluid guide fields The structure of the hydrogen diversion field is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com