Manufacturing method of tap valve body

A manufacturing method and faucet technology, which are applied in valve details, valve device, valve shell structure and other directions, can solve the problems of reducing manufacturing cost, the overall process quality needs to be improved, and the waste rate of pipe connection is low, so as to save the amount of use and process quality. The effect of easy control and fewer quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

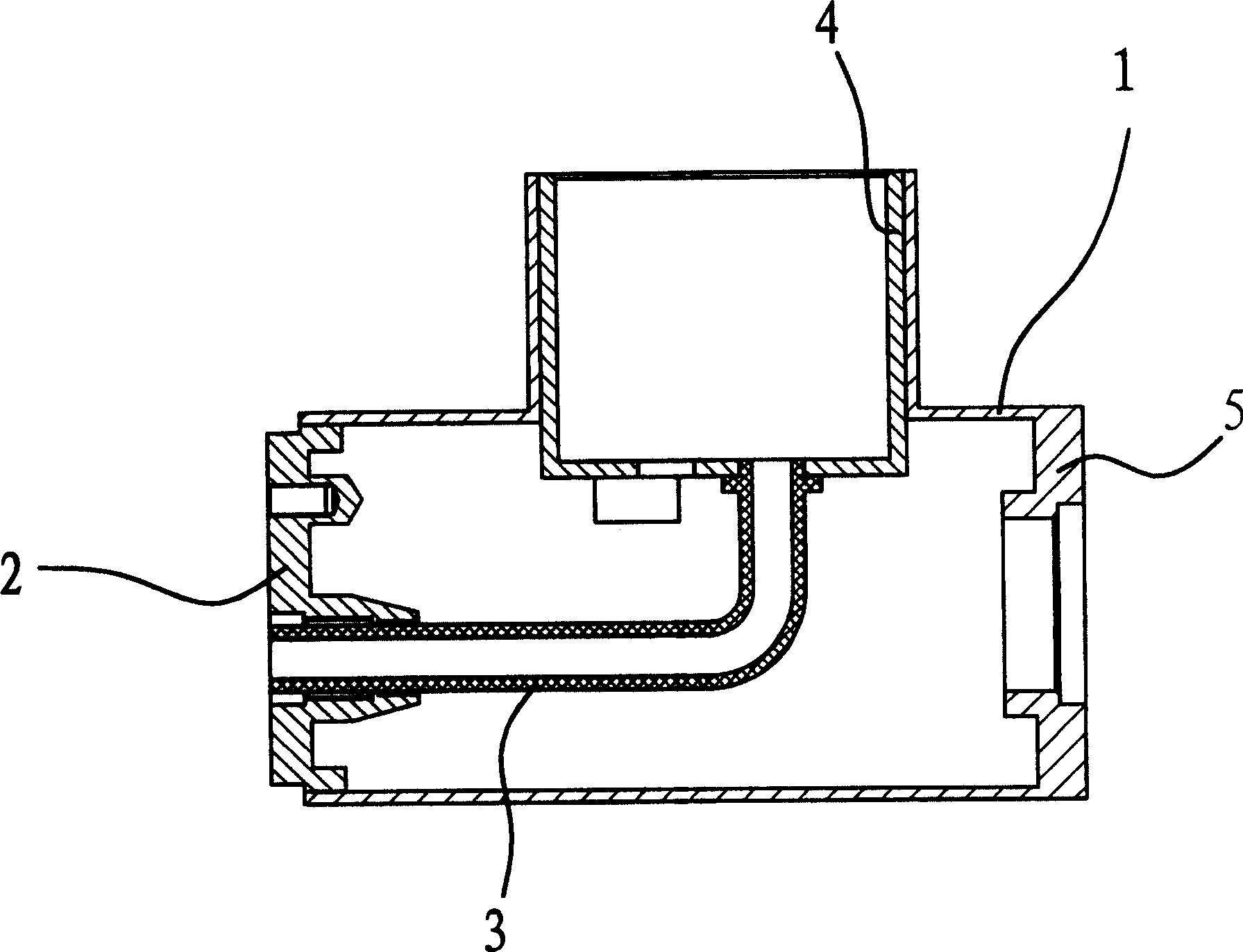

[0025] Such as figure 1 As shown, the outer shape of the valve body shell 1 is a tee. The one on the right side of the valve body shell 1 is the water outlet base 5 for connecting the water outlet pipe of the faucet, the one on the upper side is placed on the valve core seat 4, and the one on the left side is placed on the water inlet base 2.

[0026] The spool seat 4 is used to place the spool, and three water holes are arranged at the bottom, wherein two water holes are respectively connected with cold water and hot water, and are used as water inlet holes of the spool. Another hole is to connect the spool mixed water outlet hole.

[0027] Water inlet base 2 is used to place water inlet pipe, and the water inlet hole that can connect cold and hot water pipe and the screw hole that is used for fixing whole valve body are arranged on its front. There is a copper pipe that can be placed on the reverse side of the water inlet base 2 for connecting the valve core seat 4. The w...

Embodiment 2

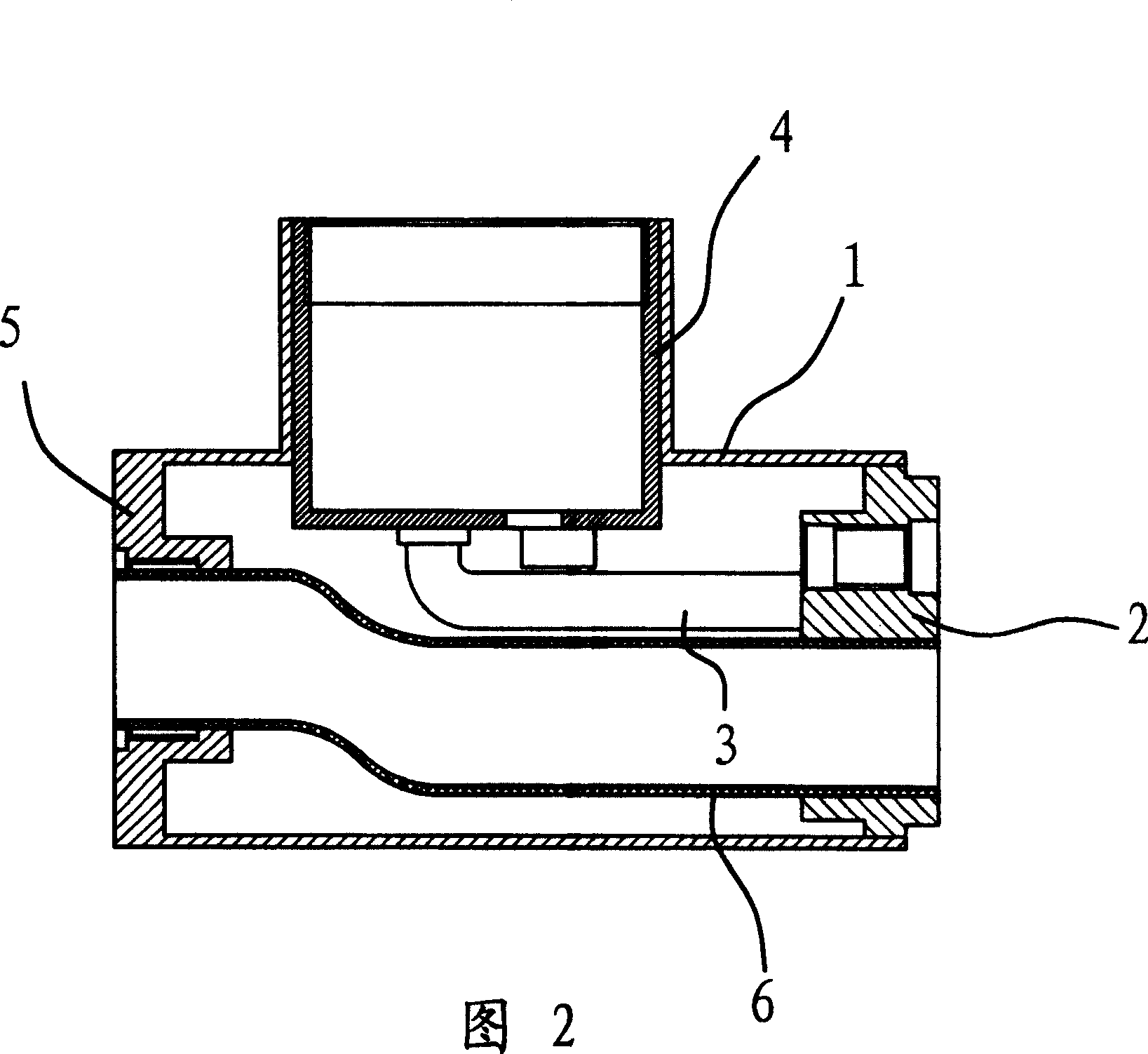

[0031] As shown in Figure 2, a manufacturing method of a faucet valve body, the valve body casing 1 is made of copper pipe extrusion: first pour tin metal inside the copper pipe, then put it into a mold, and use a 200-ton hydraulic press to extrude. After extrusion molding, the soft metals such as tin inside are melted, the valve body shell 1 and the water outlet base 5 are integrally formed at one time, the valve core seat 4 and the water inlet base 2 of the faucet valve body are cast separately through sand molds, and yellow The copper pipe is bent into the inner water pipe 3. In this embodiment, the valve body is a pull-out kitchen faucet with a guide tube 6 bent from a brass tube inside. There are four holes on the front of the water inlet base 2, which are respectively connected to the cold water inlet pipe, the hot water inlet pipe, the mixed water outlet pipe, and the screw holes for connecting the fixed valve body. First weld the inner water pipe 3 of the valve body t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com