Method of improving fluidity of phenol tar

A technology of phenol tar and fluidity, which is applied in the field of separation of phenol tar, can solve the problems of affecting the quality of hydroquinone products, the unit consumption of phenol and the increase of production cost, and the increase of production cost, so as to inhibit the dehydration condensation reaction and reduce environmental pollution , the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The mass composition of the phenol hydroxylation reaction liquid to be separated is: water content 37.5%, phenol content 53.5%, catechol content 5%, hydroquinone content 2.5%, phenol tar content 1.5%. Add NaOH to the reaction liquid at 20% by mass of the total amount of phenol tar, and mix uniformly.

[0018] The height of the dehydration tower is 800mm, the diameter of the tower is 50mm, and ceramic Raschig ring packing is used, and the packing height is 550mm; the tower height of the rectification tower is 900mm, the tower diameter is 20mm, and the packing height is 700mm. According to the product separation process of quinone, the reaction liquid is dehydrated under normal pressure, phenol is separated under reduced pressure, catechol is separated under reduced pressure, and hydroquinone and tar are separated under reduced pressure. The specific process is as follows.

[0019] Investigation of the process conditions of the dehydration tower The operating pressure is...

Embodiment 2~4

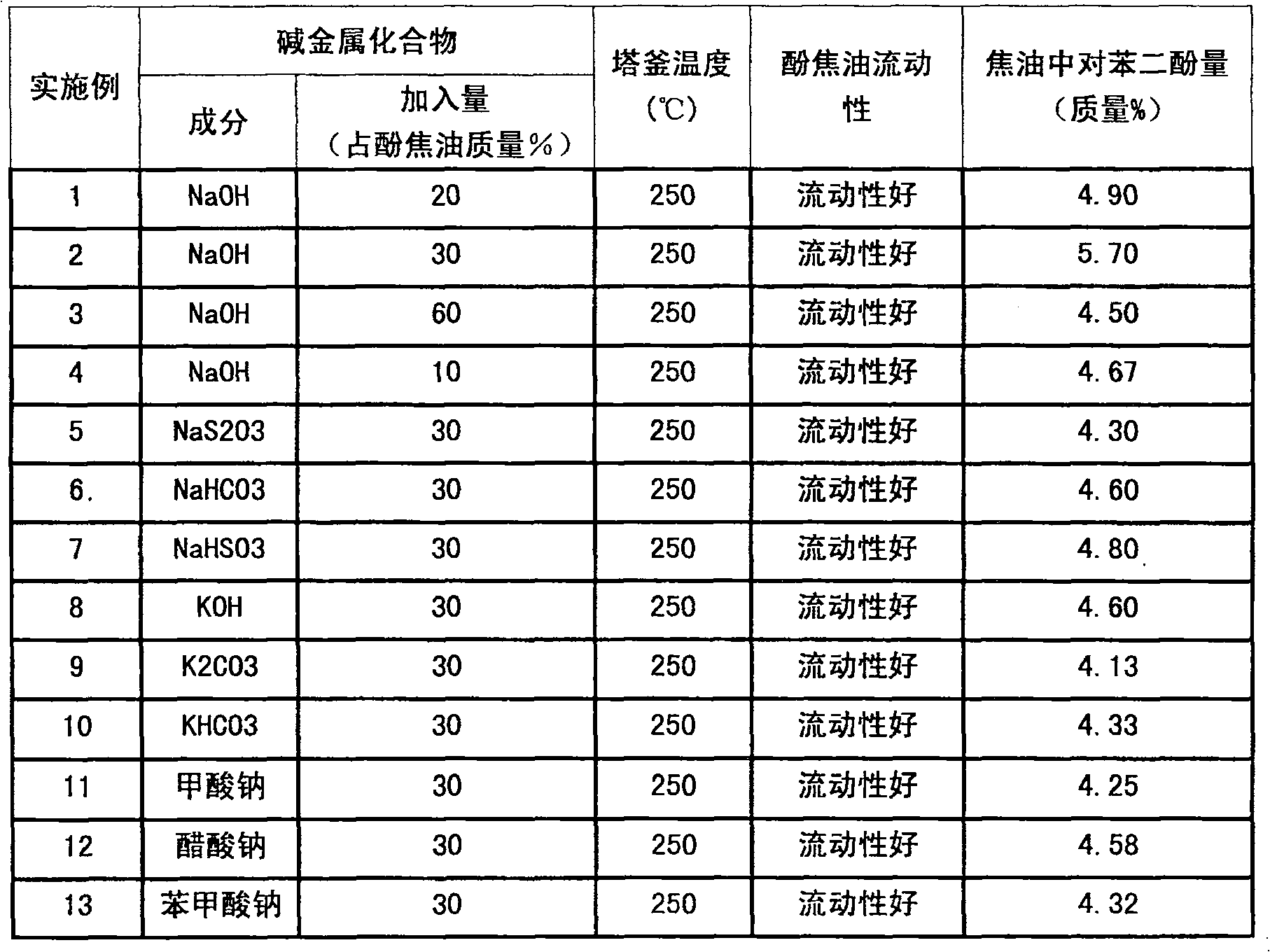

[0022] Using the same process and experimental conditions as in Example 1, changing the amount of NaOH added, the results are shown in Table 1.

Embodiment 5~13

[0024] Using the same process and experimental conditions as in Example 1, changing the type of alkali metal compound, the results are shown in Table 1.

[0025] Phenol tar composition and fluidity when adding alkali metal compound in table 1

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com