Making technology method for flash memory

A manufacturing process and flash memory technology, which is applied in the field of semiconductor integrated circuit technology, achieves the effects of small impact, improved rewritable performance, and beneficial to subsequent processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

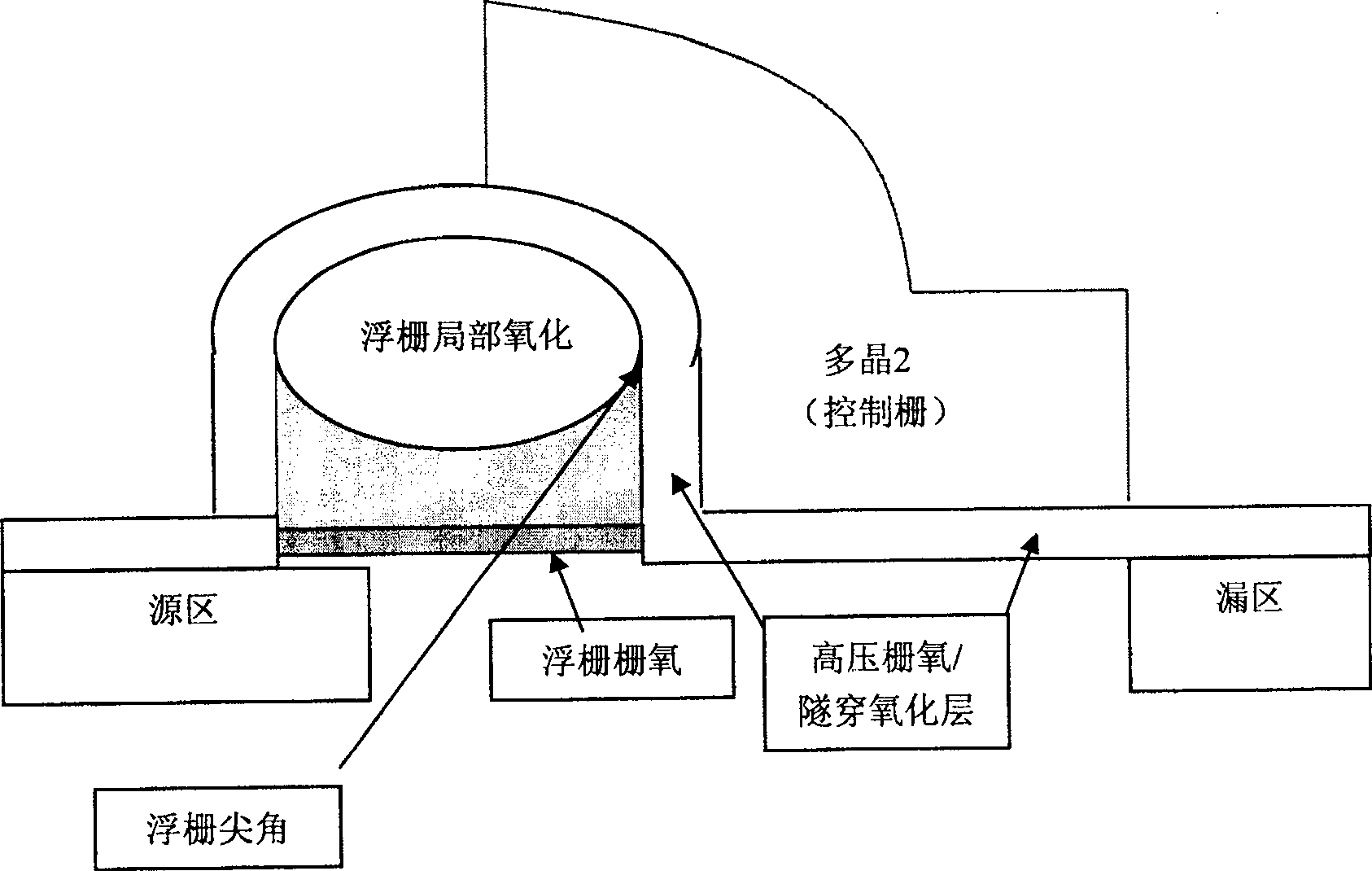

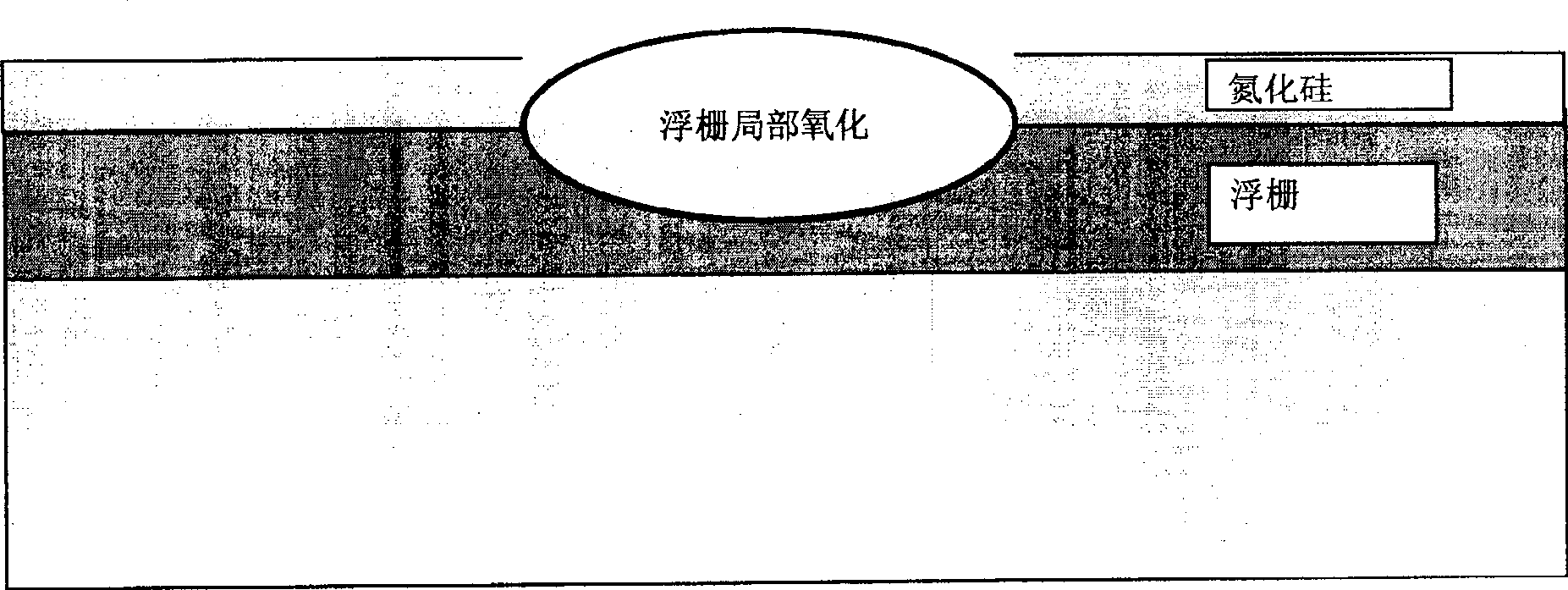

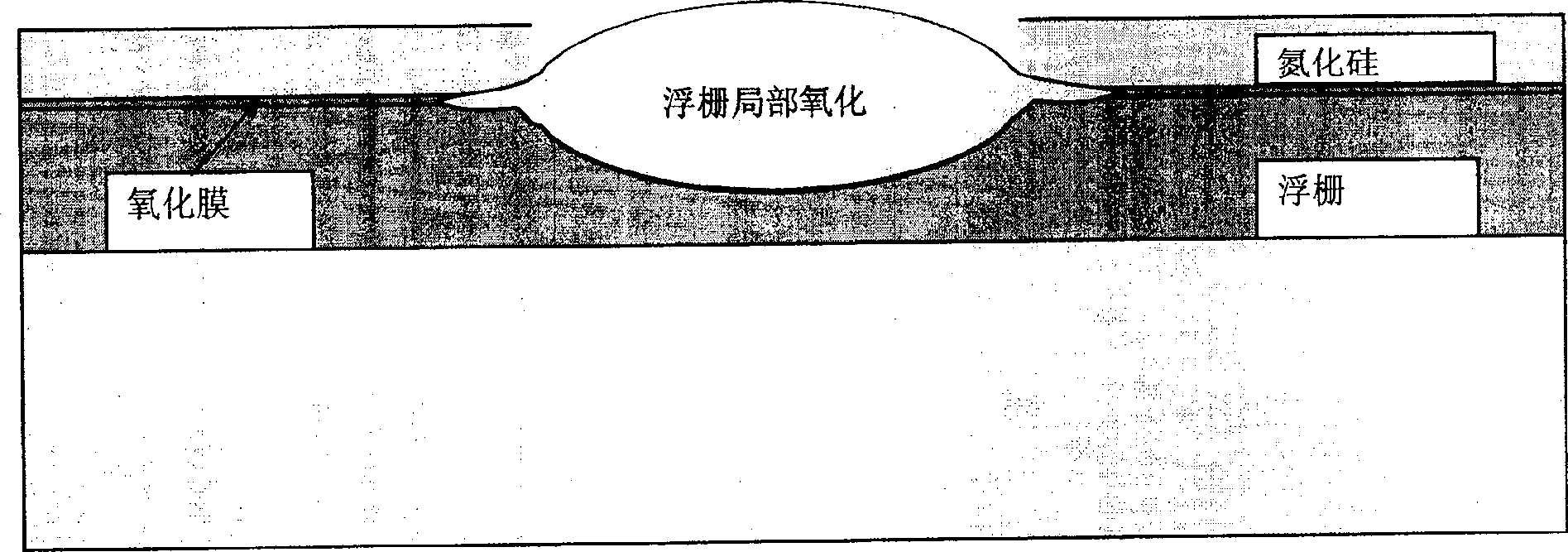

[0015] The main process steps that the present invention adopts are as follows: 1. isolation region / active area forms (same as existing technology); 2. high-voltage transistor, memory cell well implantation (same as existing technology); 3. floating gate oxidation (same as existing technology); with craftsmanship, ); 4. floating gate polycrystalline deposition (with existing technology, ); 5. A thin layer of oxide film is grown on the surface of the floating gate for about 6. Silicon nitride deposition; 7. Partial oxidation of the floating gate (same as the existing process); 8. Etching of the floating gate (same as the existing process); 9. The subsequent steps are also the same as the existing process.

[0016] The present invention compares with existing technology: steps 1~4 are the same as existing technology, after floating gate is oxidized, deposit a layer of polysilicon on the surface; Then add a process procedure, promptly grow a layer on the surface of polysilico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com