Concrete broken plate repair grouting device and method thereof

A grouting device and concrete technology, which is applied in the field of concrete, can solve the problems of time-consuming, broken boards, waste of resources, etc., and achieve the effect of short process flow, high efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

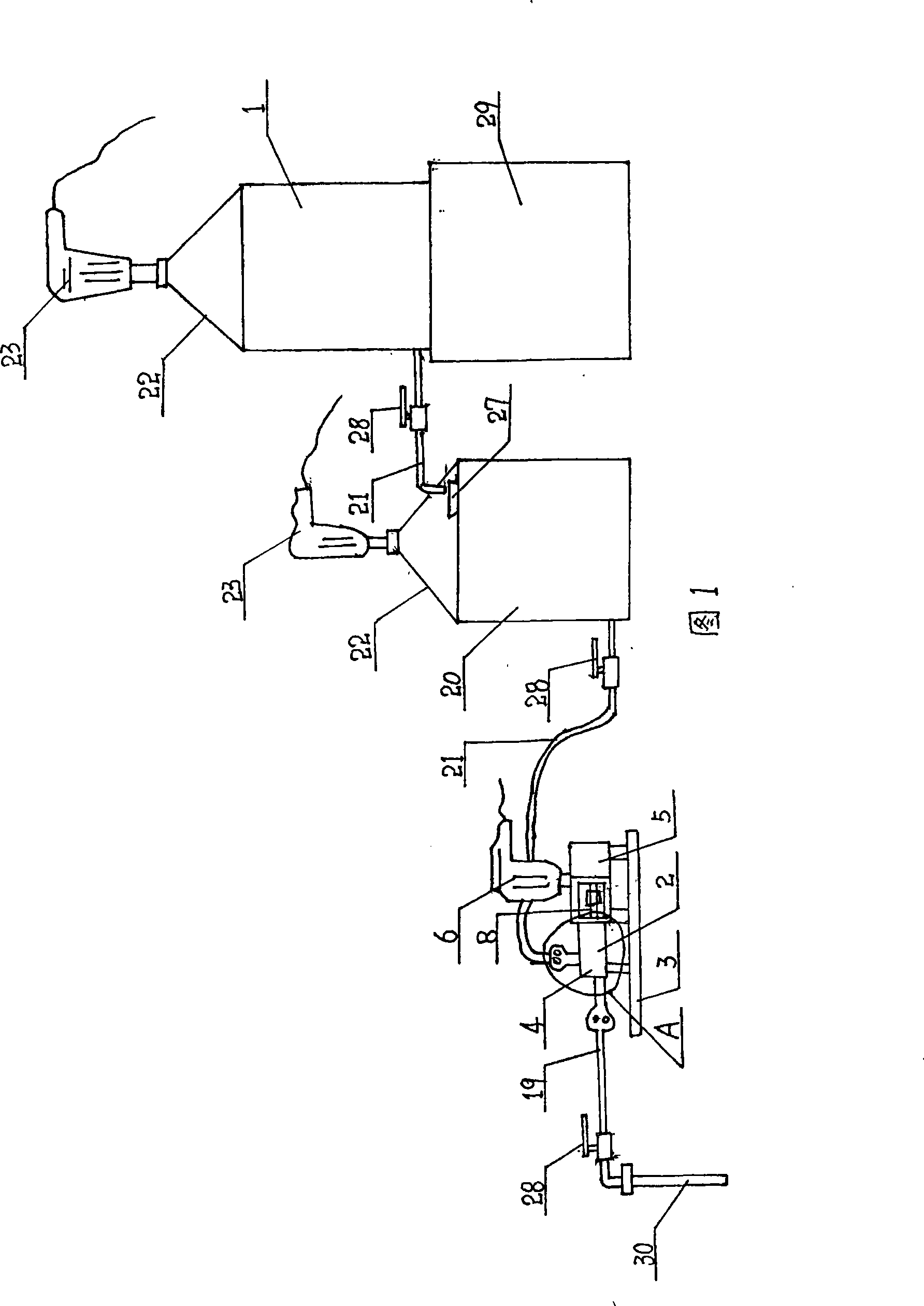

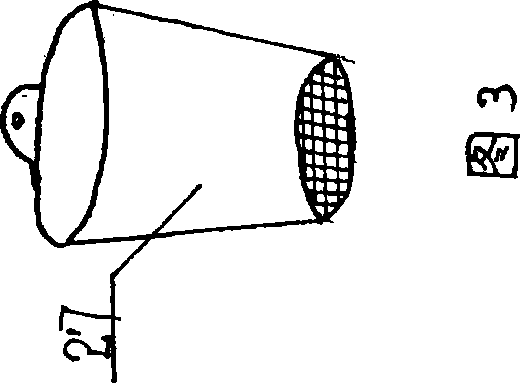

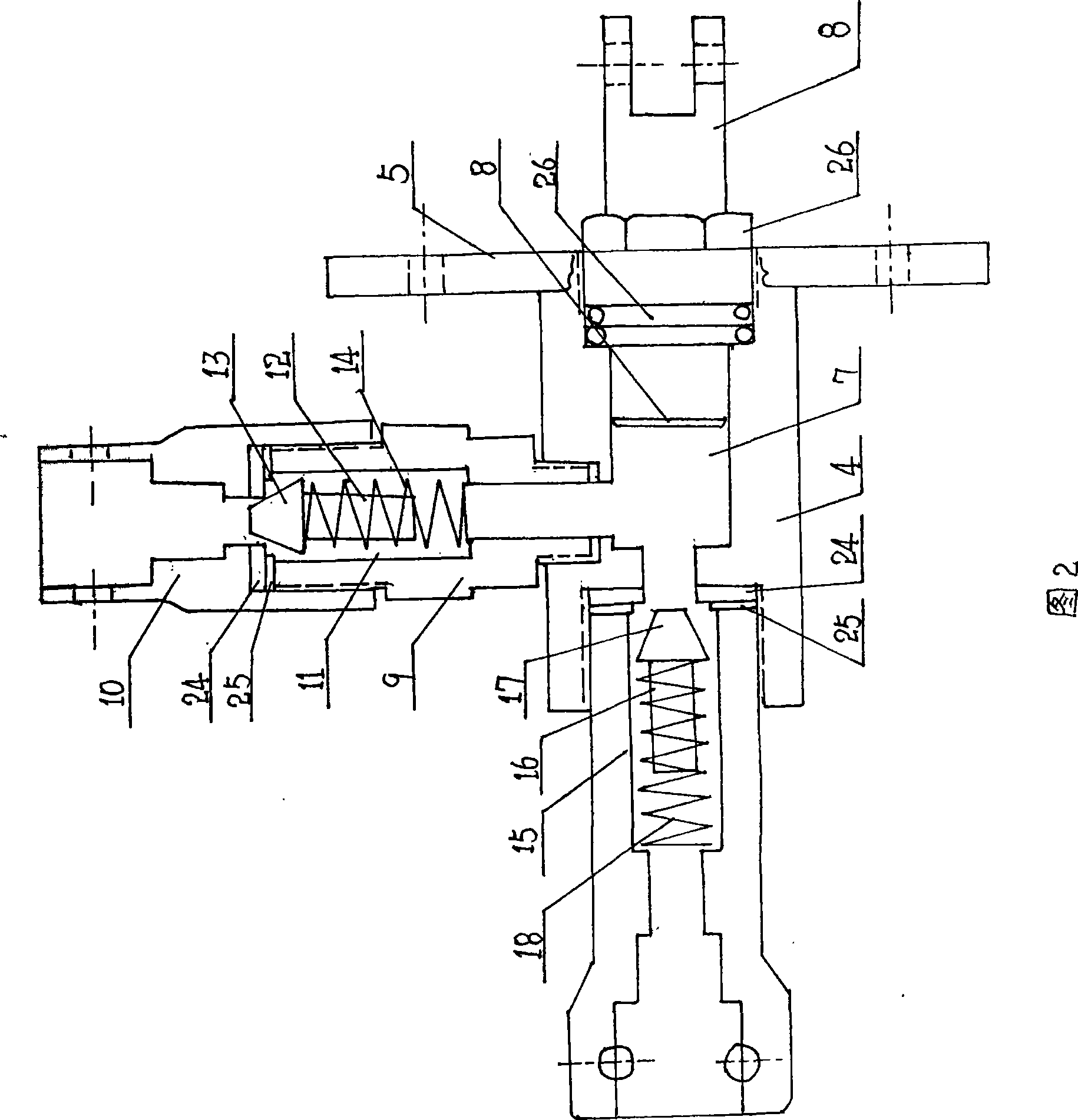

[0026] A concrete broken slab repair grouting device, comprising a slurry mixing tank 1, a pedestal 29 is arranged below it, and a high-pressure grouting pump 2 connected to the bottom of the slurry mixing tank 1 through a pipeline, the slurry mixing tank 1 is connected to the high-pressure A slurry storage tank 20 is also provided between the grouting pumps 2, and a screen 27 is arranged on the top of the slurry storage tank 20. The upper side of the slurry storage tank 20 is connected with the bottom of the slurry mixing tank 1 through the slurry outlet pipeline 21, and the other side The lower part is connected with the slurry inlet head 10 of the high-pressure grouting pump 2 through the slurry outlet pipeline 21; the slurry mixing tank 1 and the slurry storage tank 20 are respectively provided with a bracket 22, and a motor 23 is fixed on the bracket 22, and the output shaft end of the motor is connected to There is an agitator; the high-pressure grouting pump 2 includes a...

Embodiment 2

[0030] The concrete broken slab repair grouting device and its grouting process are shown in Example 1.

[0031] Adopt the above-mentioned device to complete the method for repairing broken concrete slabs, comprising the following steps: (1) adopt drilling equipment to punch holes in the cracks of the concrete slabs, then bury the grouting nozzles in the holes one by one, the number and positions of the holes should be According to the crack width and depth of the concrete slab, the grout nozzle should be sealed with the hole to prevent the grout from leaking during high-pressure grouting; Control the valve so that the grouting flow rate is 2.5L / min, and it can be injected several times until the grouting pressure and diffusion radius meet the requirements. The grout is made by mixing cement and water in a ratio of 1:1.4; when grouting, When the diffusion radius reaches 1.5m and the pressure of the high-pressure grouting pump in the above device reaches 1.0MPa, stop the grouti...

Embodiment 3

[0033] The concrete broken slab repair grouting device and its grouting process are shown in Example 1.

[0034] Adopt the above-mentioned device to complete the method for repairing broken concrete slabs, comprising the following steps: (1) adopt drilling equipment to punch holes in the cracks of the concrete slabs, then bury the grouting nozzles in the holes one by one, the number and positions of the holes should be According to the crack width and depth of the concrete slab, the grout nozzle should be sealed with the hole to prevent the grout from leaking during high-pressure grouting; Control the valve so that the grouting flow rate is 2.0L / min, and it can be injected several times until the grouting pressure and diffusion radius meet the requirements. The grout is made by mixing cement and water in a ratio of 1:1.3; when grouting, When the diffusion radius reaches 1.2m and the pressure of the high-pressure grouting pump in the above device reaches 0.95MPa, stop the grout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com