Composite electromagnetic material engine

A composite electromagnetic and starter technology, which is applied in the field of agricultural machinery, can solve the problems of copper material price rise, product promotion influence, and complex process, etc., and achieve the effect of improving electromagnetic performance, increasing welding strength and conductive area, and increasing magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

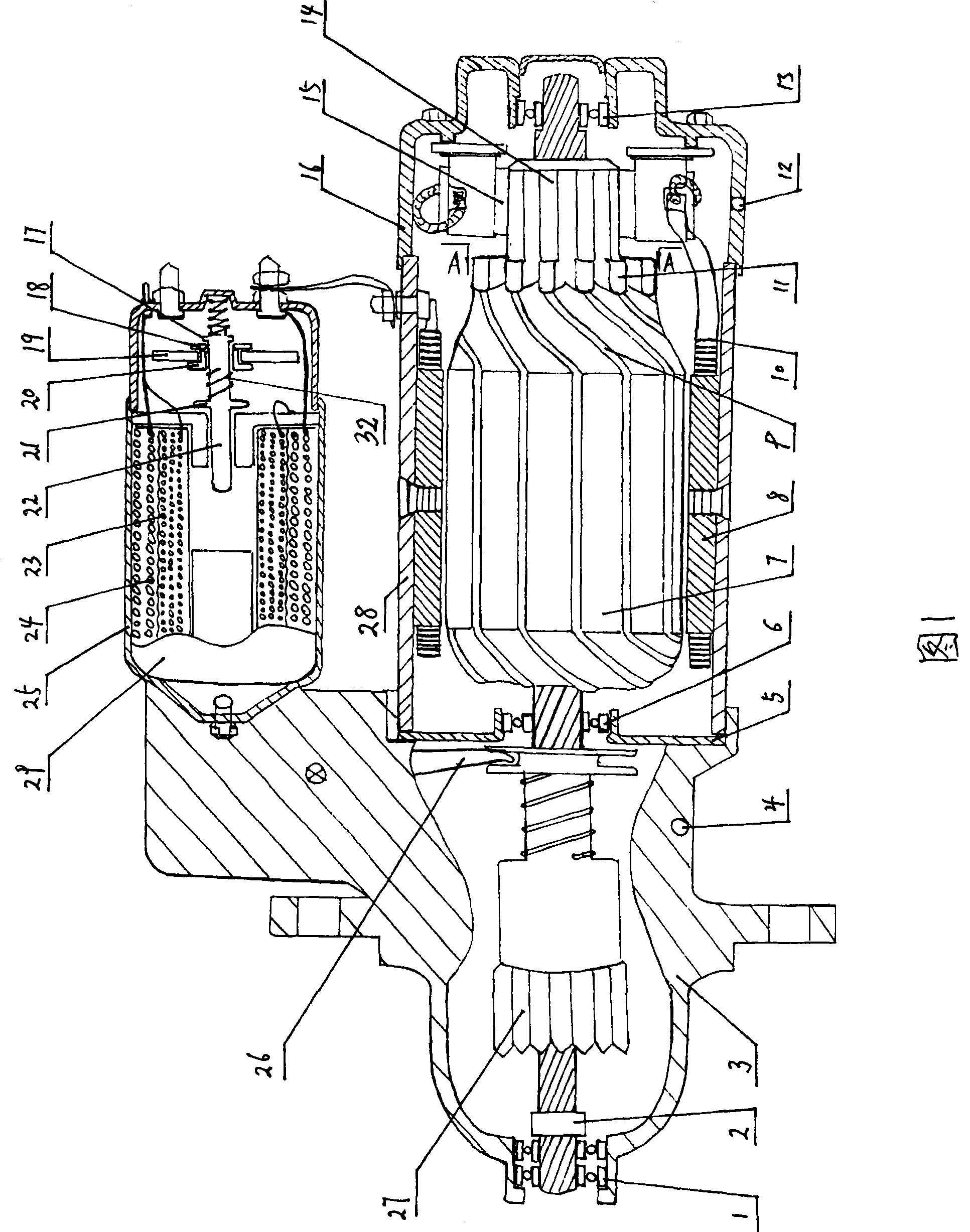

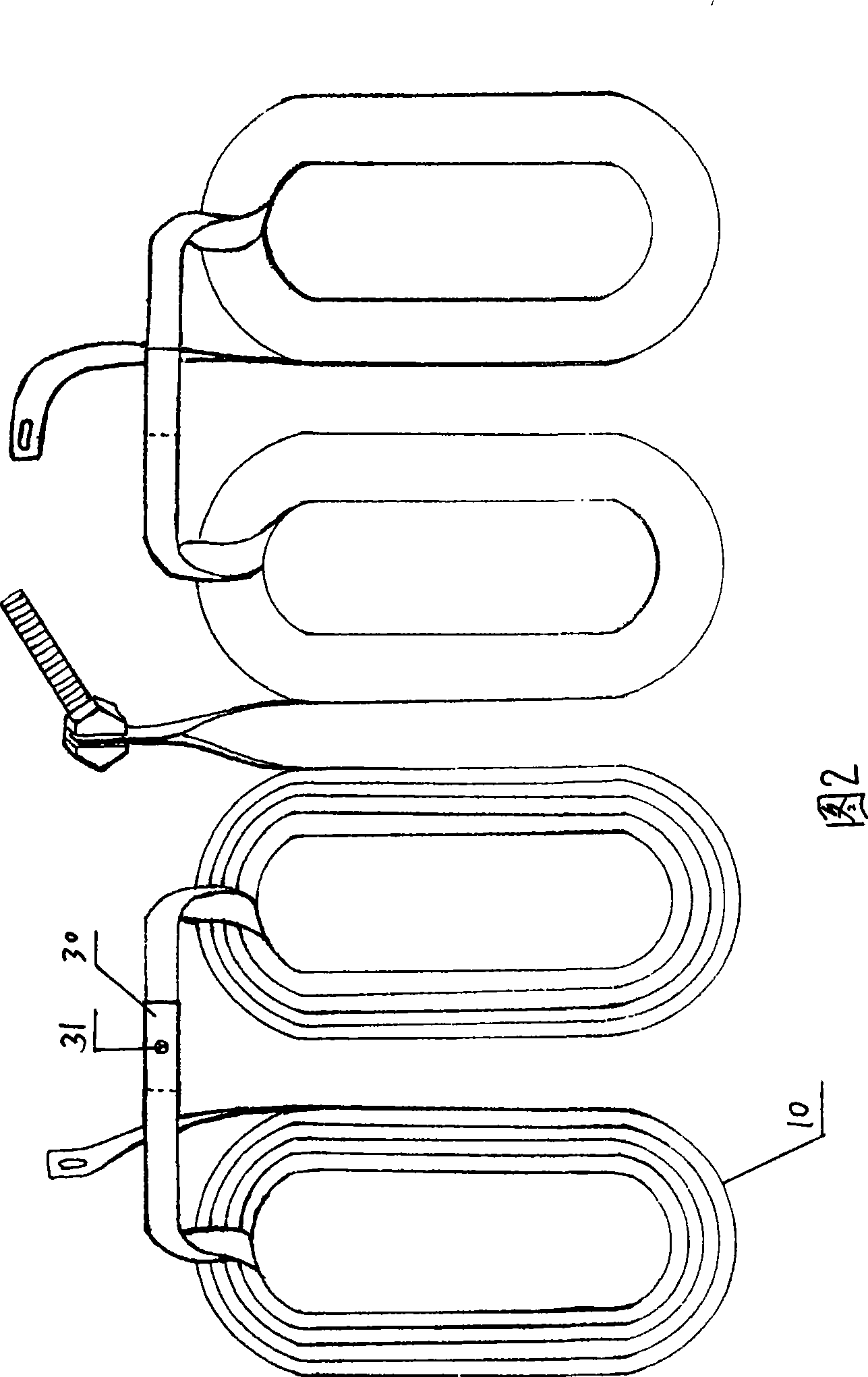

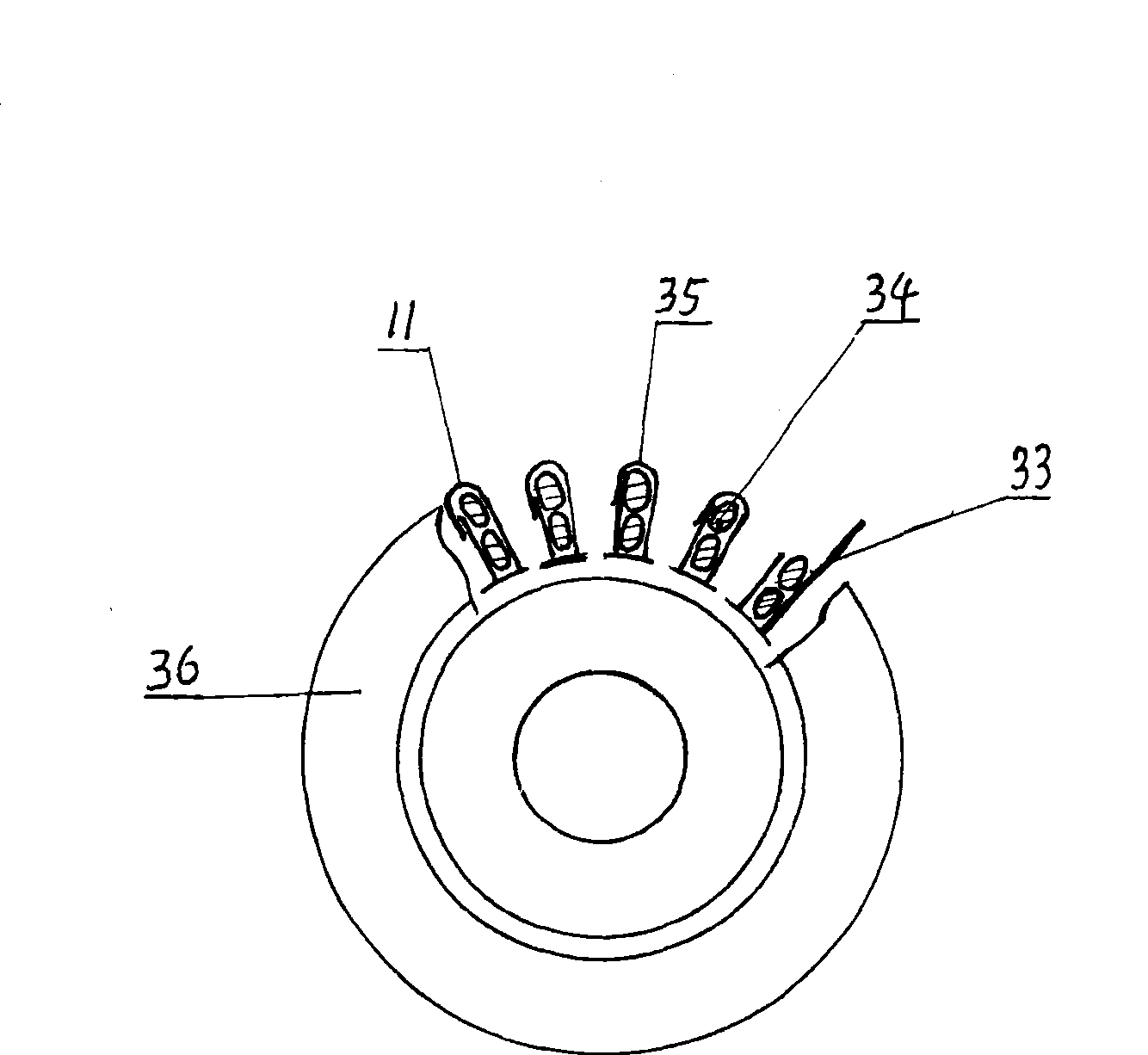

Embodiment 1

[0023] As shown in Figure 1-3, 3 in the figure is the front end cover, 28 is the casing, 16 is the rear end cover, 27 is the output gear and the intermediate partition 5, the fork 26, and the electromagnetic switch 29 arranged on the upper end of the front end cover , there are aluminum electromagnetic rotor coils 9 distributed in the slot of the rotor core of the rotor assembly. Rolling bearings 1 and 13 are respectively provided at the joints between the two ends and the front and rear end covers, and a bearing lateral positioner 2 is also provided on the inner side of the front end cover. The specific welding method of the above-mentioned wrapped copper-aluminum composite dip-soldering structure is as follows: the outer surface of the part to be welded is evenly coated with a layer of flux (product of Shanxi Taiyuan Zhaohai Co., Ltd.), and then the part or dipped in 35 -45% tin solution at a temperature of 200-260°C, the depth of immersion in the tin solution is half the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com