Method for accurately measuring trace quantity liquid refractivity

A micro-liquid, precise measurement technology, which is applied in phase influence characteristic measurement, special data processing applications, instruments, etc., can solve the problems of large amount of samples to be tested, toxicity, unfavorable measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the method and device of the present invention are not limited by the embodiments.

[0031] (1) measure the refractive index of pure water, ethanol, ethylene glycol and glycerol liquid with the present invention

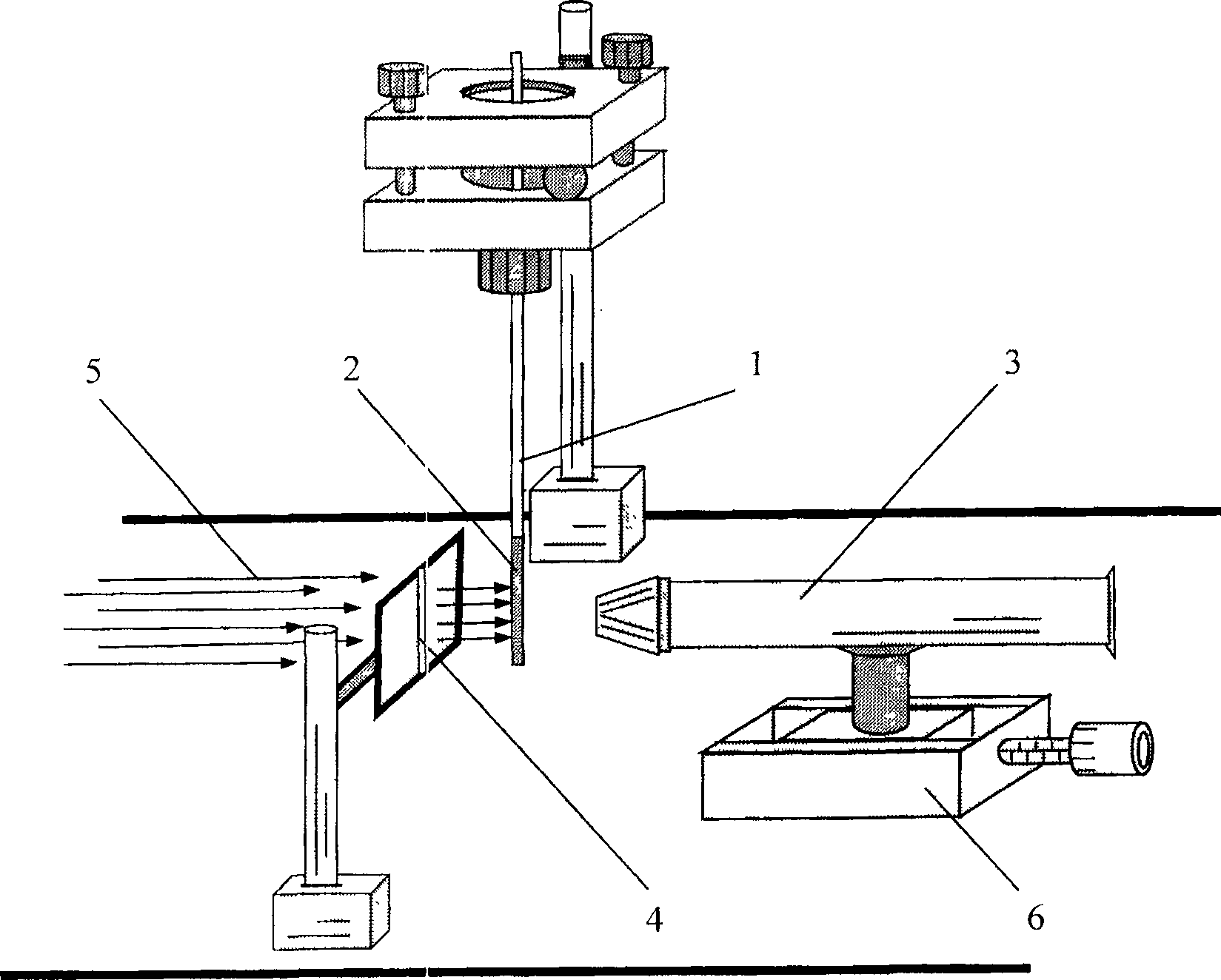

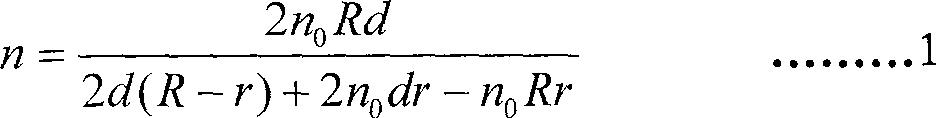

[0032] Such as figure 1 As shown, the microscope lens barrel 3 with a magnification of 10×10 is fixed on a one-dimensional micro-movement platform 6 with a minimum displacement value of 0.01mm, so that the optical axis of the lens barrel 3 is parallel to the one-dimensional micro-motion direction of the displacement platform , composed of a reading microscope. A helium-neon laser with a wavelength of 594.1nm is used as the light source 5, and the parameter corresponding to the glass capillary 1 used is n 0 =1.5153, R=0.768mm, r=0.345mm, the liquids to be tested are pure water, ethanol, ethylene glycol and glycerol solutions respectively. The He-Ne laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com