Process for preparing functional poly propylene material

A polypropylene material and functionalization technology, which is applied in the field of preparation of functionalized polypropylene materials, can solve the problems of product depth and mechanical property decline, and achieve the effects of reducing degradation reactions, reducing production costs, and reducing radiation treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

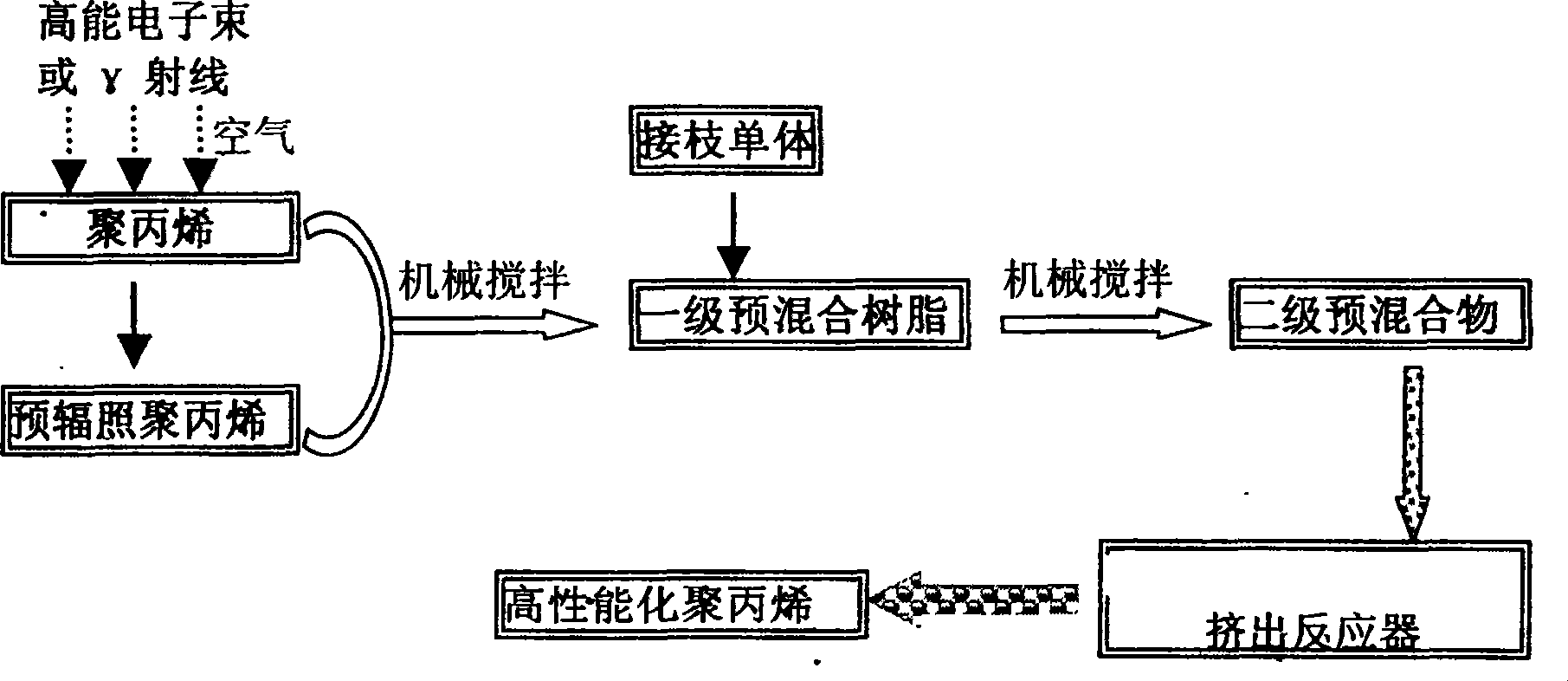

Method used

Image

Examples

Embodiment 1

[0038] The raw materials are copolymerized polypropylene and pre-irradiated copolymerized polypropylene. The polar unsaturated monomer is acrylic acid. The melt flow rate of the copolymerized polypropylene is 3.3g / 10min. It is isotactic polypropylene and its form is powder. analytically pure reagents.

[0039] The pre-irradiation treatment of polypropylene is to spread the copolymerized polypropylene powder evenly in an open container, and then transport it through the irradiation area by an automatic conveying device, and pre-irradiate it with electron beams under air conditions. Dose rate 10 5 kGy / h, the irradiation time is 0.1s, and the melt flow rate of polypropylene after irradiation is 43.3g / 10min.

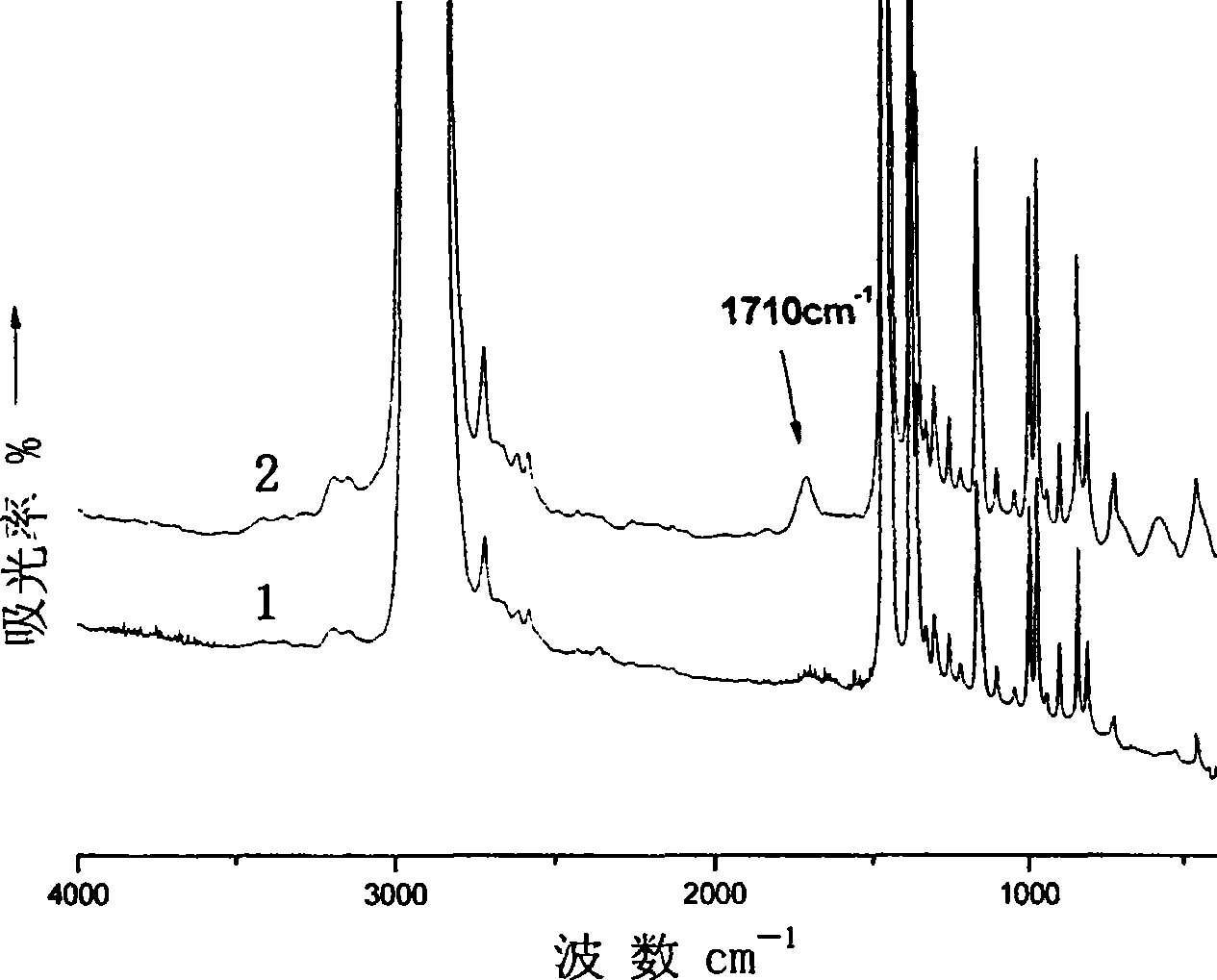

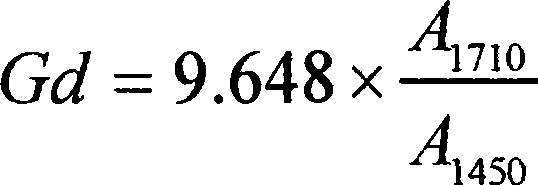

[0040] 5 parts (quality) of the above-mentioned pre-irradiated polypropylene and 95 parts (quality) of non-irradiated polypropylene are mechanically mixed to obtain a primary premixed resin; Mechanically mixing with the above primary premix to obtain a secondary premix; th...

Embodiment 2

[0047] The raw materials are the same as in Example 1, the mass ratio of unirradiated polypropylene and pre-irradiated polypropylene is changed to 90:10, the amount of polar unsaturated monomer acrylic acid is 0.8%, and the rest of the steps are the same as in Example 1.

[0048] The graft rate that obtains product is 0.17%, and its melt flow rate is 4.3g / 10min, and the value slightly larger than raw material polypropylene, shows that there is the degradation reaction of part in grafting process, has produced a small amount of low molecular weight product, color It is also basically the same as the raw material polypropylene. The test results of other physical and mechanical properties are shown in Table 1.

Embodiment 3

[0053] The raw material is the same as in Example 1, the amount of pre-irradiated polypropylene is increased so that the mass ratio of the unirradiated polypropylene is 15:85, the amount of polar unsaturated monomer acrylic acid is 0.8%, and the remaining steps are the same as in Example 1. same.

[0054] The grafting ratio of the obtained product is 0.27%, its melt flow rate is 3.9g / 10min, and the tensile properties and impact strength are all lower than those of the raw material. This is because the increase in the amount of pre-irradiated polypropylene produces more degradation , resulting in a decrease in mechanical properties, proving that the amount of pre-irradiated polypropylene as the "initiator" can be easily adjusted to control the degree of degradation of the product. The test results of other physical and mechanical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com