A method for extracting tetrahydro-2-ethylanthraquinone from working solution for producing hydrogen peroxide by anthraquinone method

A technology of ethyl anthraquinone and hydrogen peroxide, applied in quinone separation/purification, organic chemistry and other directions, can solve the problems of increasing cost and time, complicated steps, etc., and achieve the effect of improving hydrogenation efficiency, low cost and reducing anthraquinone degradation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

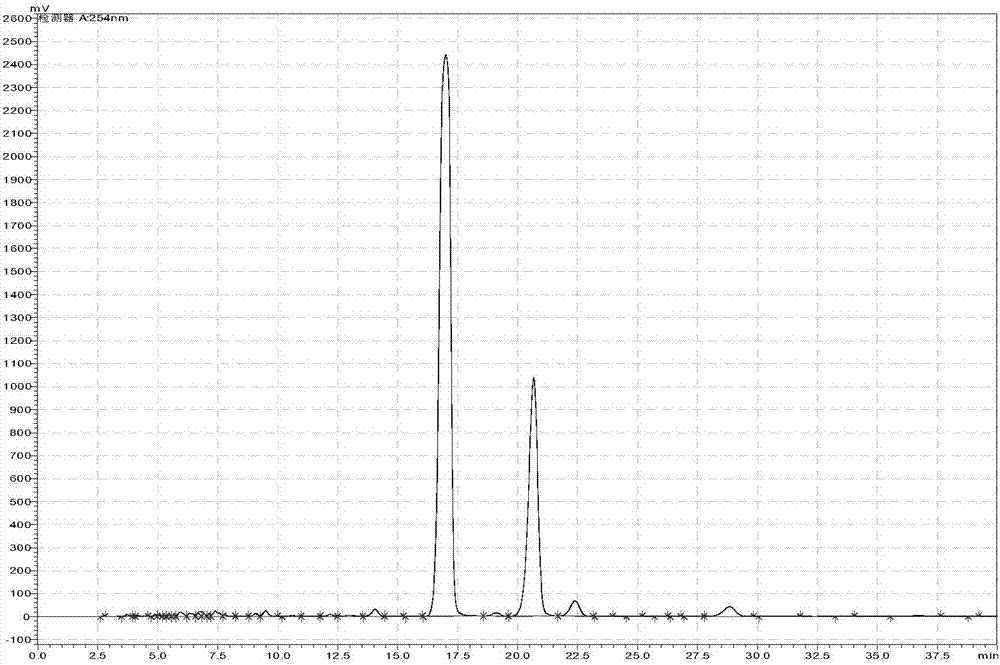

[0028] Take 300mL of the circulating working solution in a rotary evaporator, distill at -0.1MPa, 110°C for 2h, put the residual liquid in an oven at 110°C, and cool it down to 15°C after 1.5h, at this time, a large number of crystals are precipitated at the bottom. Suction filter the distillate, wash the filter cake 3 times with ethanol, and then dry it at 60°C. The obtained crystals were placed in a Buchner funnel with filter paper, and heavy aromatic hydrocarbons were added dropwise at -0.1 MPa until the needle crystals disappeared and a large number of flaky crystals appeared on the filter paper. The filtrate was collected and evaporated to dryness in a rotary evaporator to obtain needle-like crystals.

Embodiment 2

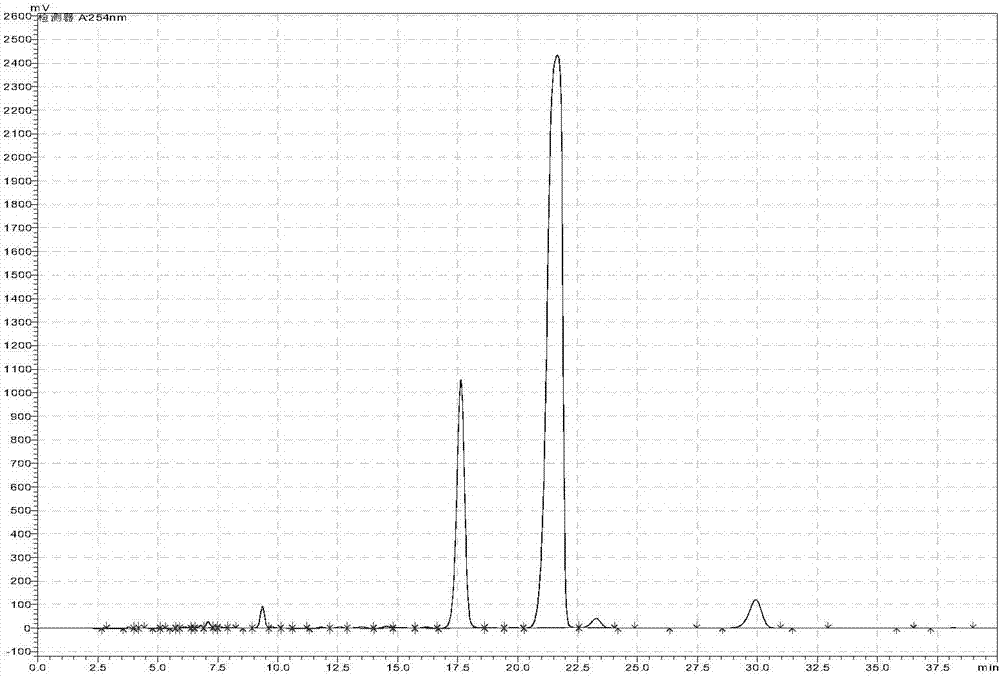

[0030] Take 300mL of the circulating working solution in a rotary evaporator, distill at -0.05MPa, 120°C for 1.5h, then put it in an oven at 120°C, and cool it down to 15°C after 2h, when a large amount of crystals are precipitated at the bottom. Suction filter the distillate, wash the filter cake 3 times with ethanol, and then dry it at 70°C. The obtained crystals were placed in a Buchner funnel with filter paper, and pseudocumene was added dropwise at -0.05 MPa until the needle crystals disappeared and a large number of flaky crystals appeared on the filter paper. The filtrate was collected and evaporated to dryness in a rotary evaporator to obtain needle-like crystals.

Embodiment 3

[0032]Take 300mL of the circulating working solution in a rotary evaporator, distill at -0.03MPa, 130°C for 4.5h, put it in an oven at 130°C, and cool it down to 15°C after 3h, when a large amount of crystals are precipitated at the bottom. Suction filter the distillate, wash the filter cake 3 times with ethanol, and then dry it at 55°C. The obtained crystals were placed in a Buchner funnel with filter paper, and 1,3,5-trimethylbenzene was added dropwise at -0.03 MPa until the needle-like crystals disappeared and a large number of flaky crystals appeared on the filter paper. The filtrate was collected and evaporated to dryness in a rotary evaporator to obtain needle-like crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com