Method for processing chemical fibre titanium white from normal TiO2 by drying surface treatment

A surface treatment, chemical fiber titanium dioxide technology, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of limiting the application range of chemical fiber titanium dioxide, high operating costs, and unavoidable waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

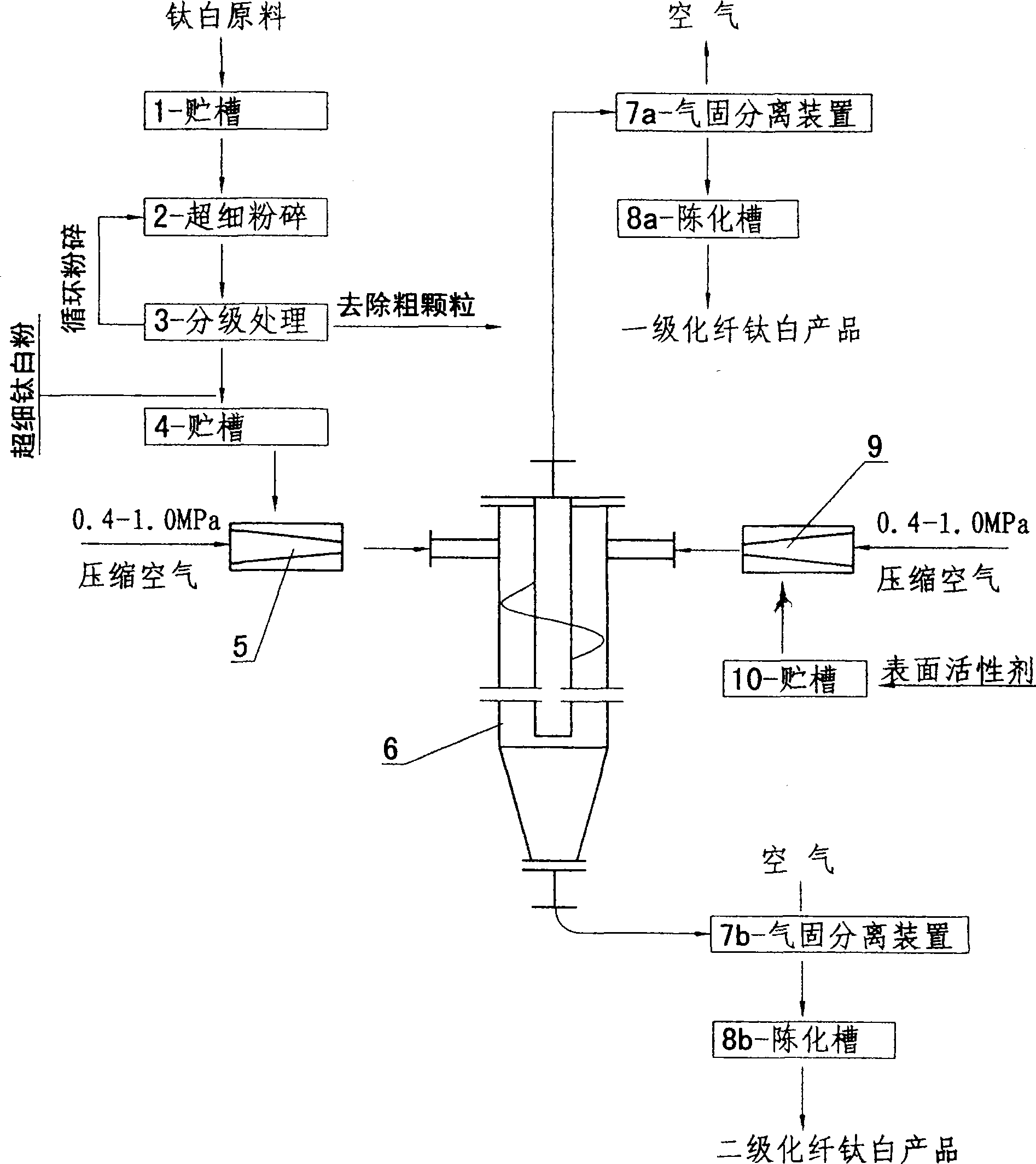

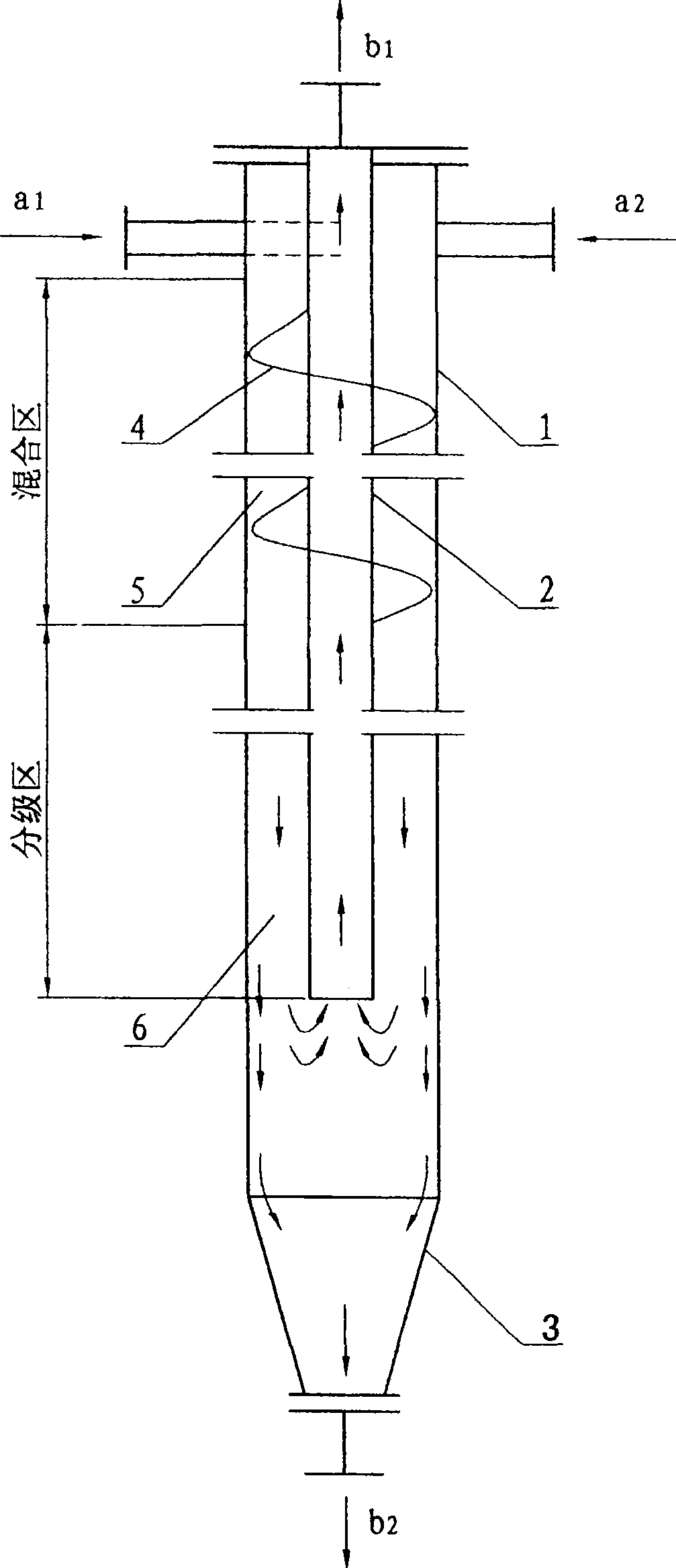

[0061] (1) Pretreatment of raw materials:

[0062] Take 1000 kg of ordinary titanium dioxide with a particle size of 325 mesh (equivalent to a particle size of 43 μm), and carry out ultrafine crushing and classification in a jet mill with a classification device powered by 0.6-1.0 MPa compressed air. Remove particles with a particle size > 3 ~ 5 μm (can be used for other purposes); ultrafine titanium dioxide with a particle size up to the standard (ie particle size ≤ 2 μm) is used as raw material for the next step of processing; particles with a particle size > 2 μm and < 3 μm are automatically returned It enters the airflow crushing system for circular crushing until it reaches the standard.

[0063] Through pretreatment, at least 900 kg of qualified ultrafine titanium dioxide (particle size ≤ 2 μm) raw materials can be obtained for the next step of dry surface treatment.

[0064] (2) Dry surface treatment of ultrafine titanium dioxide at room temperature

[0065] Weigh 100...

Embodiment 2

[0071] Except that the surfactant used is "Sorbitol 0.3kg+Spen20 (spen20) 0.1kg", all the other raw materials and operating process are the same as in Example 1. Finally, about 22.1kg of the first-grade chemical fiber titanium dioxide product with a particle size of <1μm was obtained, and about 78.2kg of the second-grade chemical fiber titanium dioxide product with a particle size of ≥1μm to a radius of ≤2μm was obtained.

[0072] Tested according to conventional methods, the water dispersibility is 95.5% and 95.1% respectively; the heat stability is >55min; the product quality is better than the existing chemical fiber titanium dioxide.

Embodiment 3

[0074] Except that the tensio-active agent used is " tartaric acid 0.25kg+ lauryl alcohol 0.20kg ", all the other raw materials and operation process are all the same as embodiment 1. Finally, 22.1 kg of the first-grade chemical fiber titanium dioxide product with a particle size of <1 μm, and 78.2 kg of the second-grade chemical fiber titanium dioxide product with a particle size of ≥1 μm to ≤2 μm were obtained.

[0075] According to conventional test methods, the water dispersibility of the above products is measured to be 95.7% and 95.3% respectively; the thermal stability is greater than 46 minutes; the quality of the products is better than the existing chemical fiber titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com