Method for producing plastic ball valve

The technology of a plastic ball valve and its manufacturing method is applied in the directions of valve details, valve device, valve shell structure, etc., which can solve the problems of increased motion friction, large valve ball holding force, and difficulty in rotating the one-piece valve core. The effect of area reduction and motion friction reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

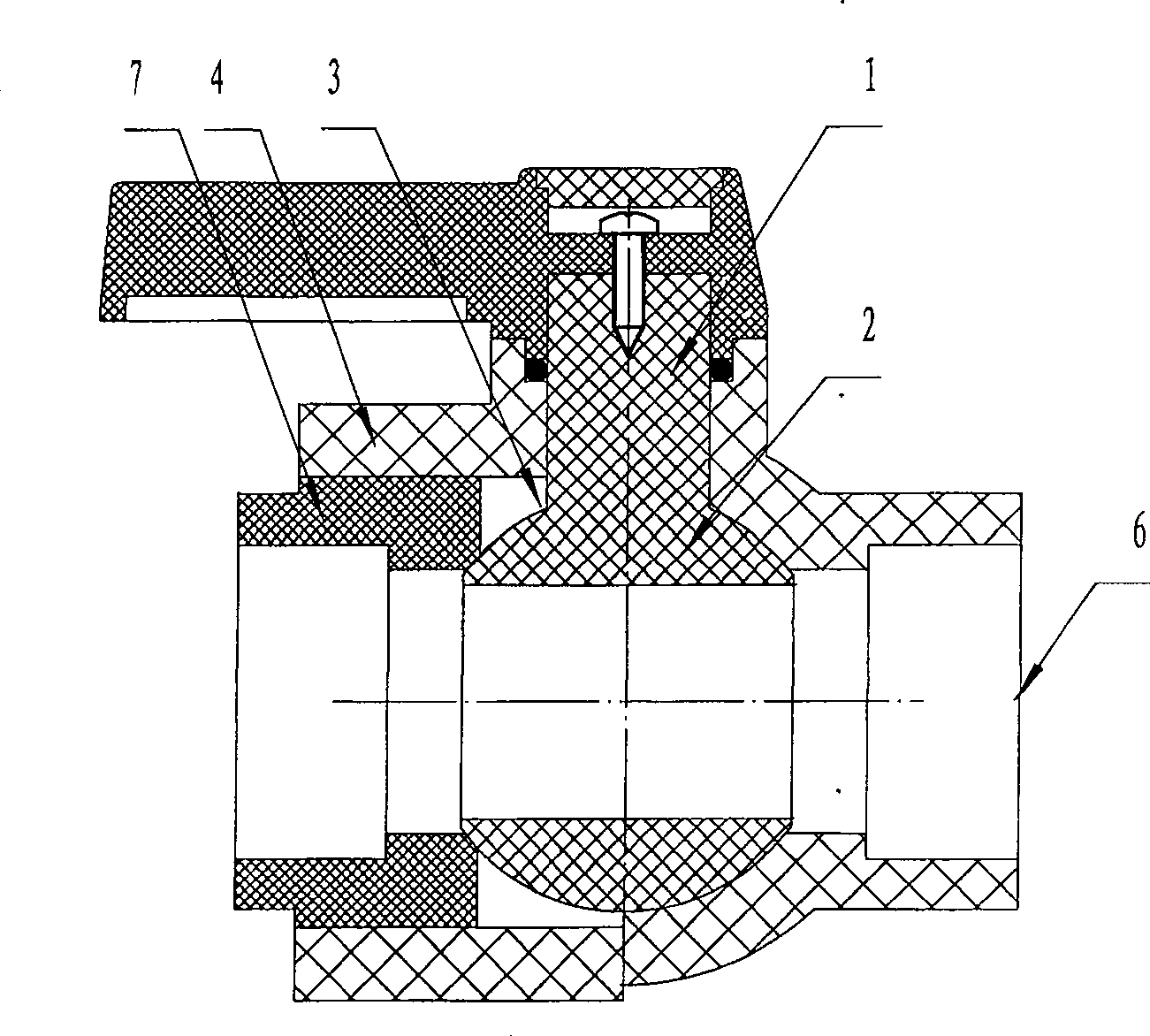

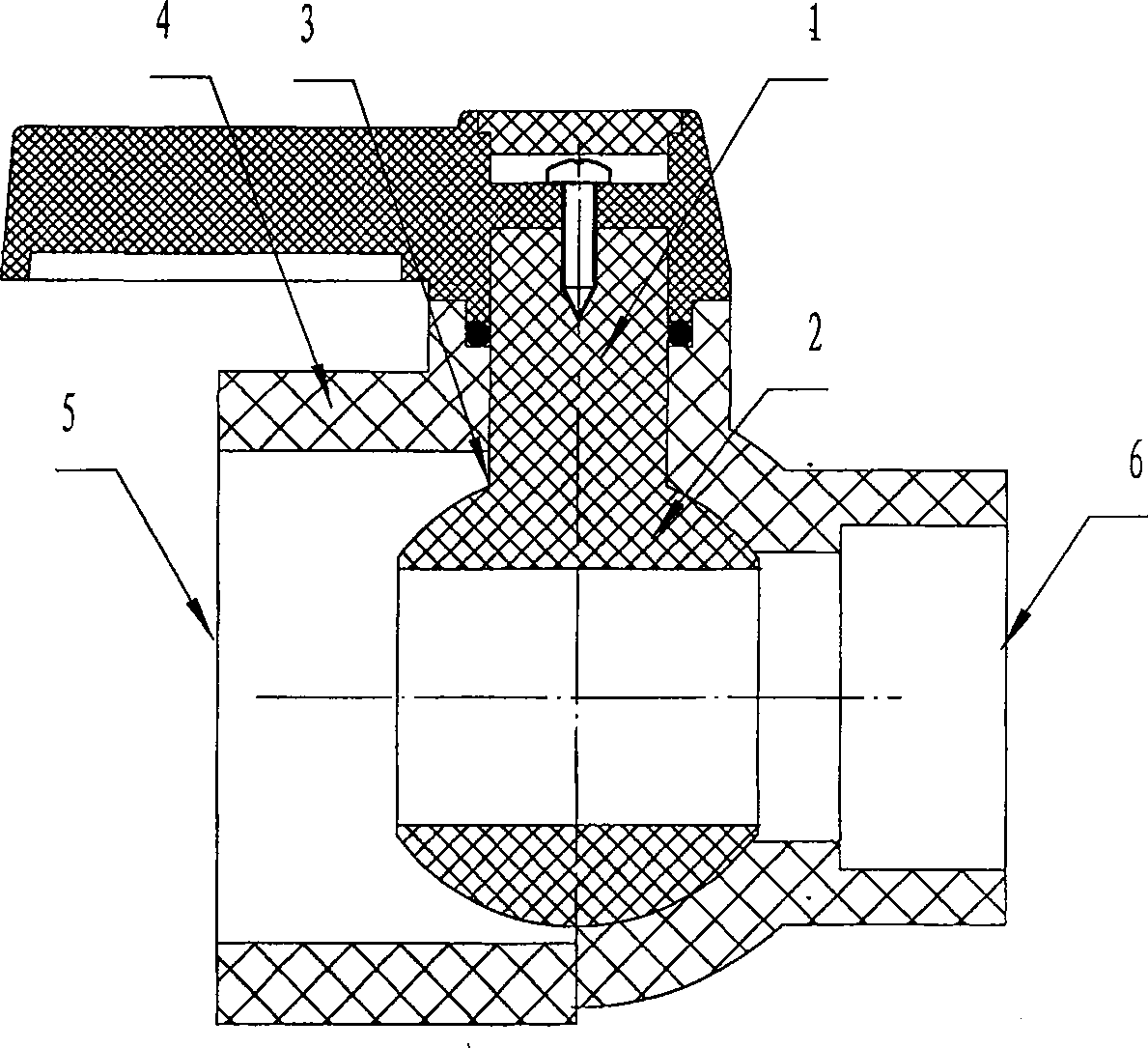

[0066] Example 1: Such as Figure 1~2 As shown, the manufacturing method of the plastic ball valve of this embodiment is characterized by sequentially following the steps:

[0067] a. Fabricate an integrated valve core 3 that connects the valve stem 1 and the valve ball 2 as a whole; in order to make the integrated valve core light, corrosion-resistant and simple in processing technology, plastic materials are used in this embodiment to make the integrated valve core 3 Spool 3.

[0068] b. Put the valve ball of the above-mentioned integrated valve core and the position of the valve stem connected with the valve ball into the mold for making the plastic ball valve body;

[0069] c. The plastic material is heated and melted and then cooled in a mold to form a plastic ball valve body 4. The molded plastic ball valve body 4 has openings 5 and 6 leading to the location of the valve ball 2 on both sides, and the top has After the plastic ball valve body 4 is cooled and formed, the val...

Embodiment 2

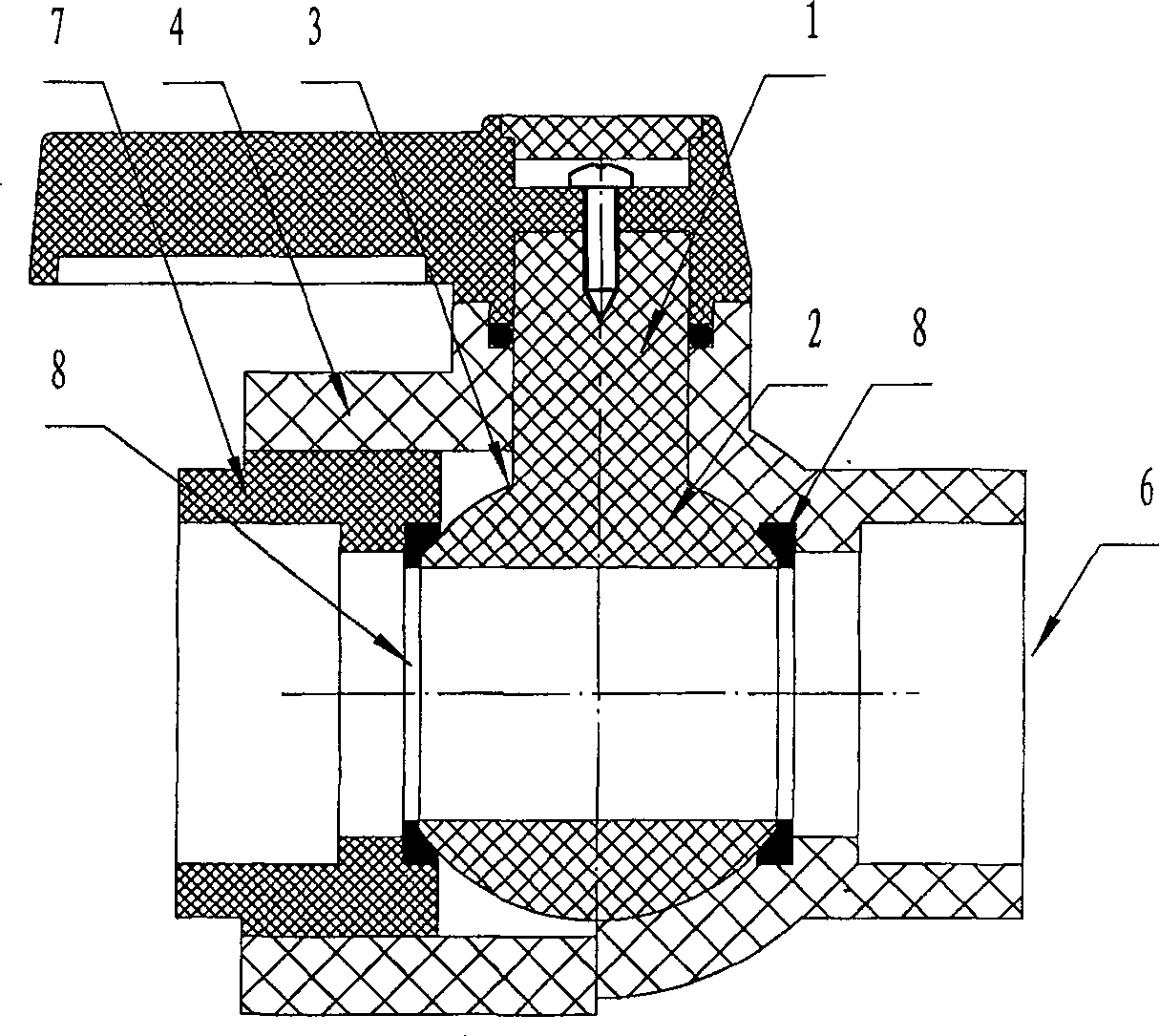

[0071] Example 2: Such as Figure 3~4 As shown, this embodiment is similar to embodiment 1, except that in step d, the plastic valve cover 7 and the inner wall of the plastic ball valve body 4 are provided with seals on the surface that is compatible with the valve ball of the integrated valve core. Face 8.

Embodiment 3

[0072] Example 3: Such as Figure 5~6 As shown, this embodiment is similar to Embodiment 2, except that in step d, the plastic valve cover 7 is provided with a sealing surface 8 that cooperates with the spherical surface of the valve ball 2 of the integrated valve core to form a sealing pair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com