Method for construction of multi-point integral top pulling steel case beam

A steel box girder and jacking technology, which is applied in bridges, bridge materials, bridge construction, etc., can solve the problems of heavy workload, large amount of steel, poor synchronism and stability of jacking, etc., and achieve synchronous jacking, Easy to operate, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

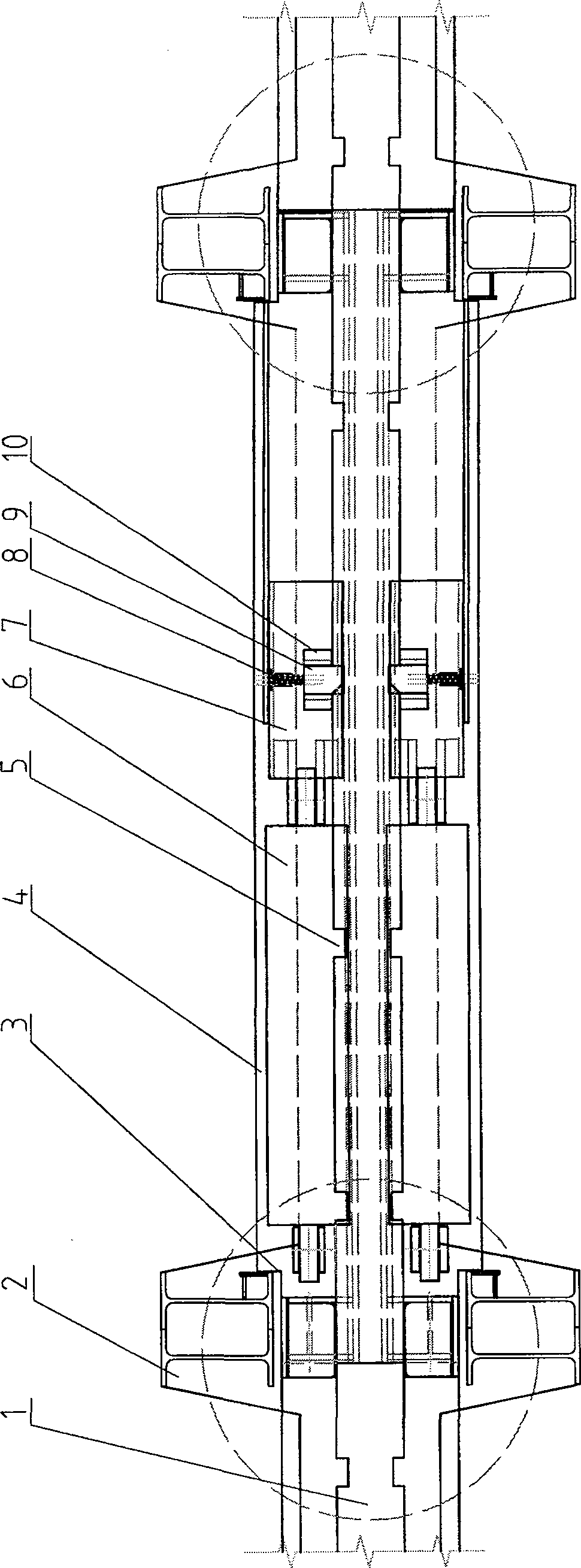

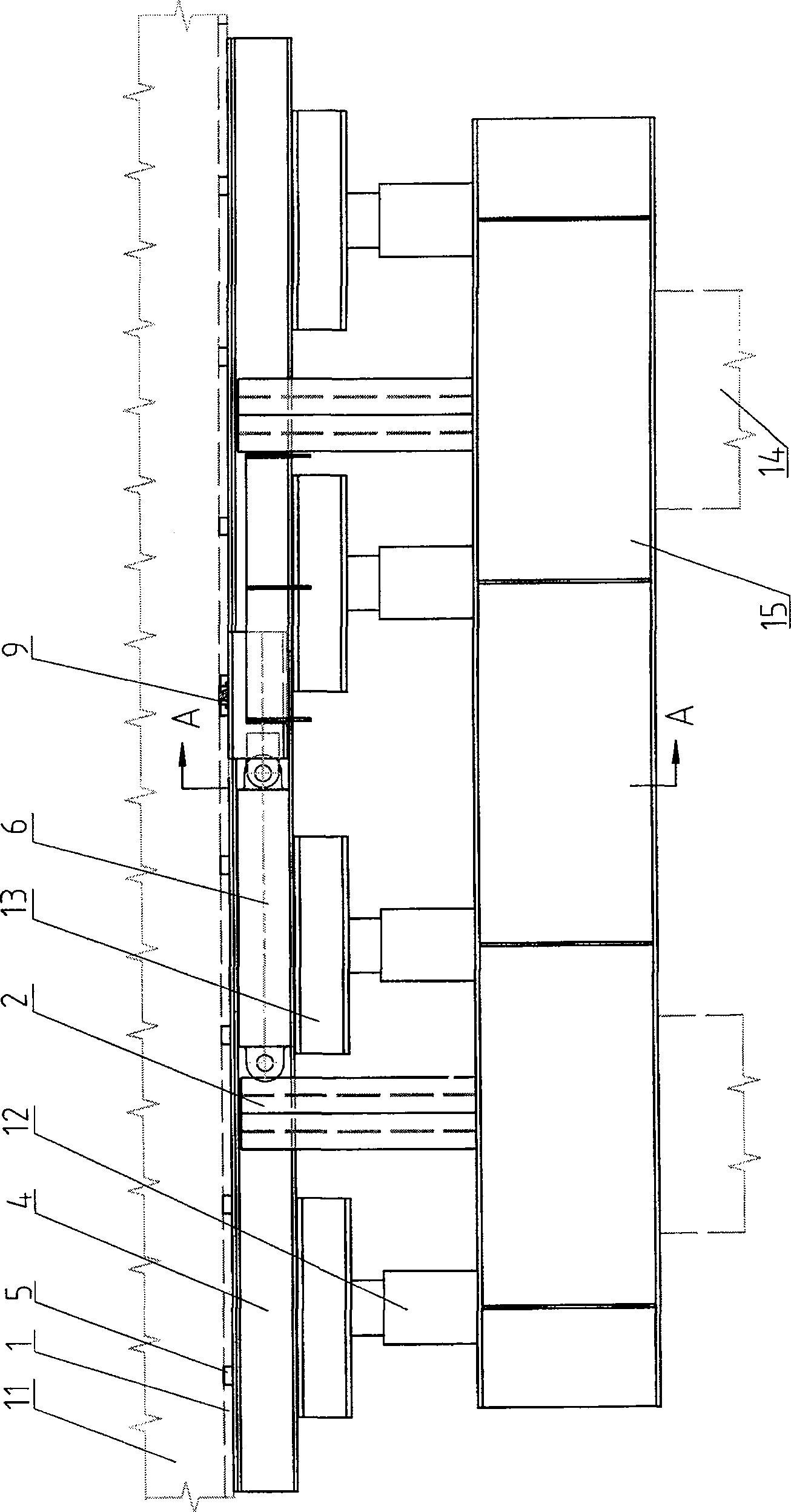

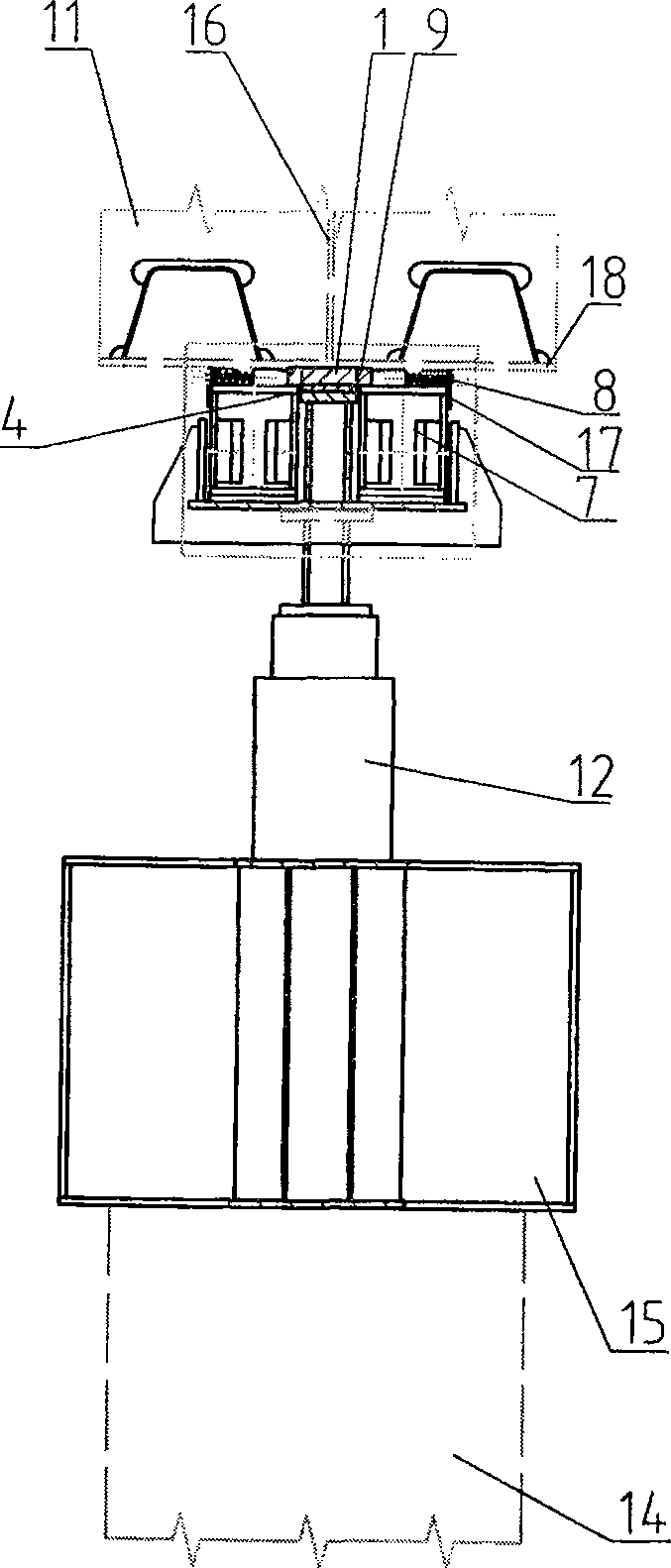

[0040] Refer to the attached Figures 1 to 7 , the multi-point integral jacking steel box girder construction method of the present invention adopts the following steps to carry out construction:

[0041] a. Set up a pushing platform 25 near the first temporary upset on the shore, connect it together with the first temporary upset 14, and set a backing plate and an elevation adjustment device on it.

[0042] b. Set up a group of jacking systems 22 on each temporary pier 14 and the crossbeam of the cable tower 23, and all the jacking systems are uniformly programmed. The jacking system is set up as follows:

[0043] 1) Install the pad beam 15 on the above-mentioned temporary pier, install the jacking jack 12, the short sliding beam 13 and the main sliding beam 4 in sequence on the pad beam, and the top pushing jack 6 is also arranged on the short sliding beam, that is, the main sliding beam two A jacking jack is arranged on each side; a pressure sensor and a displacement sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com