X ray diffraction instrument and method for detecting macro stress in micro area

A macro-stress and micro-area technology, applied in the direction of measuring device, measuring force, using mechanical device, etc., can solve the problems of difficult macro-stress detection, analysis and detection, inability to stress change gradient and stress distribution inhomogeneity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

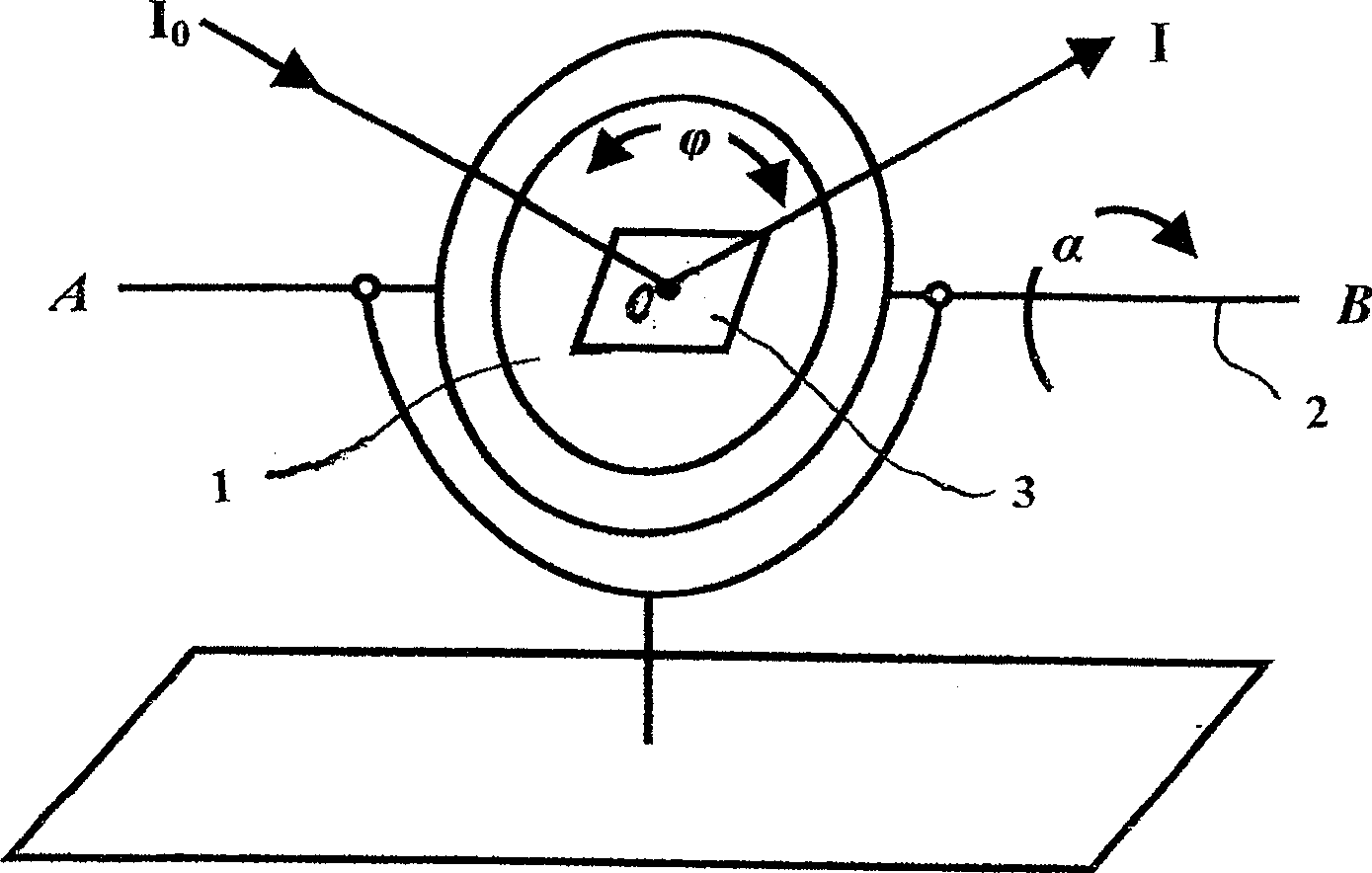

[0032] Embodiment 1 The self-made device in the present invention—a rotating detection platform for macroscopic stress detection in micro-regions by the roll method.

[0033] See figure 1 , in the selection of D8C 2 In the case of a diffractometer, the length, width and height of the sample carrier can be selected between 80mm and 100mm. The rotating detection platform of the present invention can be installed on the D8C precisely and conveniently 2 The three-axis translational sample carrier of the equipment is installed on the D8C 2 The function of the device and the detection accuracy are not affected in any way. figure 1 Among them, 1 is the table top, that is, the table top of the rotating detection table, 2 is the roll axis, that is, the straight line AB, 3 is the sample to be tested, I 0 and I are incident x-rays and diffracted x-rays. Point O is the X-ray irradiation point (that is, the macroscopic stress detection point).

[0034] The tested sample and the rotat...

Embodiment 2

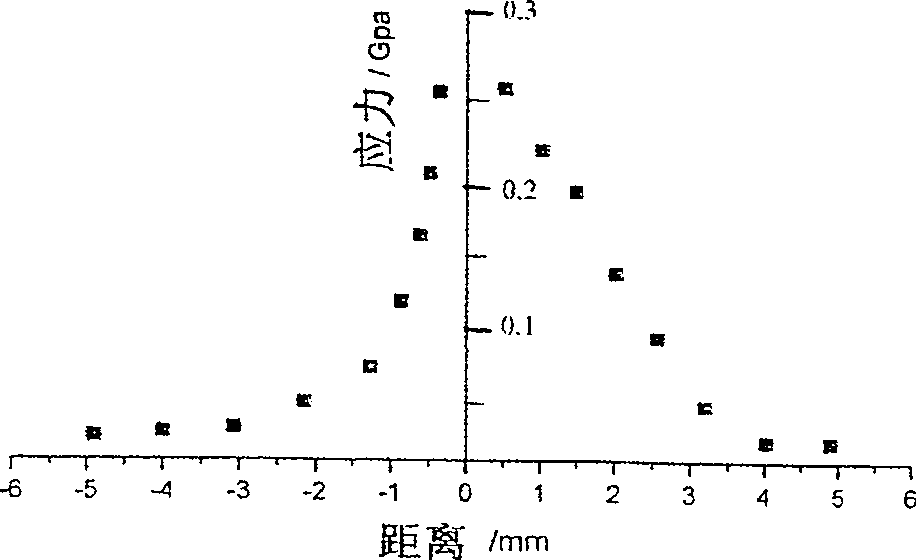

[0035] Example 2 Detection of Macroscopic Stress Variation Gradient in the Weld Seam Area of Diffusion Welded Parts by Expansion Difference

[0036] The welded center column is 10mm Cu alloy, the inner diameter of the outer ring Ti alloy is 10mm. The thickness of the weldment is 5mm. The central column and the outer ring are closely matched, and the expansion difference diffusion welding is realized under the condition of 850 degrees Celsius in vacuum.

[0037] Choose to measure the gradient of stress within 10mm in the direction perpendicular to the weld. According to the implementation steps of the micro-area macro stress detection of the aforementioned roll method of the present invention, with the weld seam as the center, 17 test points are selected in the range of ± 5mm, and each test point must be at α=0°; α=16 °; α = 24°; α = 30° to make a set of data, and focus precisely under the microscope, the experimental conditions are guaranteed to be exactly the same.

[...

Embodiment 3

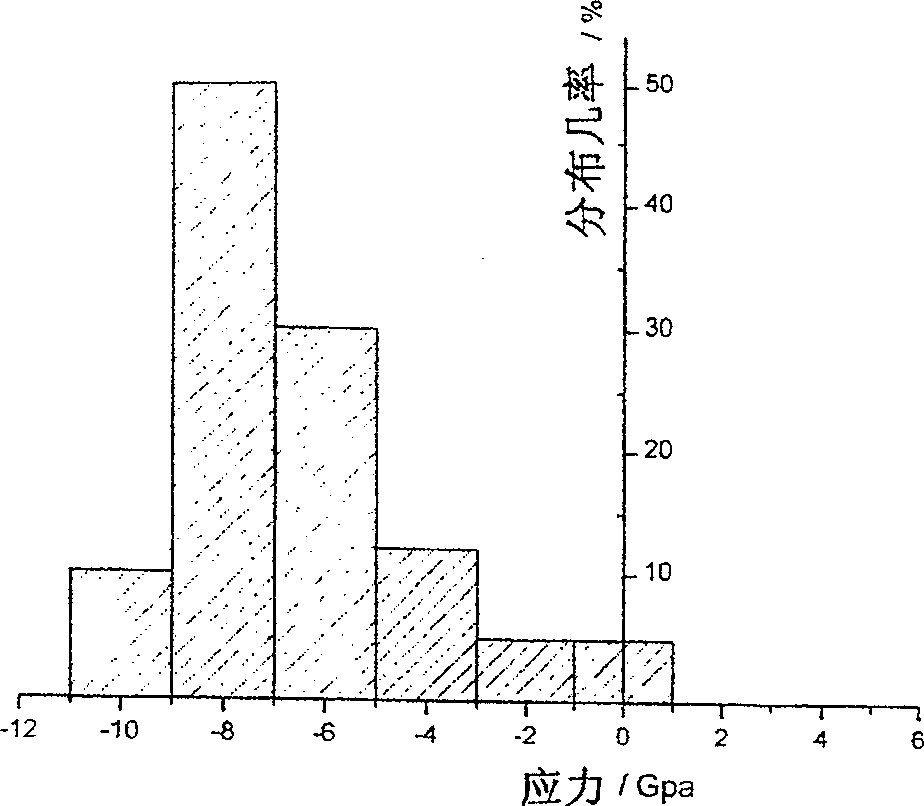

[0041] Example 3 Detection of stress distribution inhomogeneity of a diamond film grown by CVD on a Mo substrate.

[0042] The electron-enhanced chemical vapor deposition (EA-CVD) method is used to grow a diamond polycrystalline film on the Mo substrate at 800-900 degrees Celsius, with a thickness of 0.3mm.

[0043] According to the implementation steps of the small area stress detection of the roll method of the present invention, a 2mm × 2mm detection area is selected on the film, and 50 detection points are randomly selected in the area, and each test point must be at α=0°; α=16 °; α = 24°; α = 30° to make a set of data, and focus precisely under the microscope, the experimental conditions are guaranteed to be exactly the same, and the macroscopic stress in the same direction is measured.

[0044] The occurrence probability of different stress values is calculated from the test results to characterize the inconsistency of the stress in the test area (see image 3 ).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com