Petroleum drilling pipe shocking and sliding wear tester

A wear test, oil drilling technology, applied in the application of repetitive force/pulse force to test material strength, test wear resistance, use mechanical devices, etc., can solve problems such as inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manner of the present invention will be further described in detail below in conjunction with the drawings and specific examples.

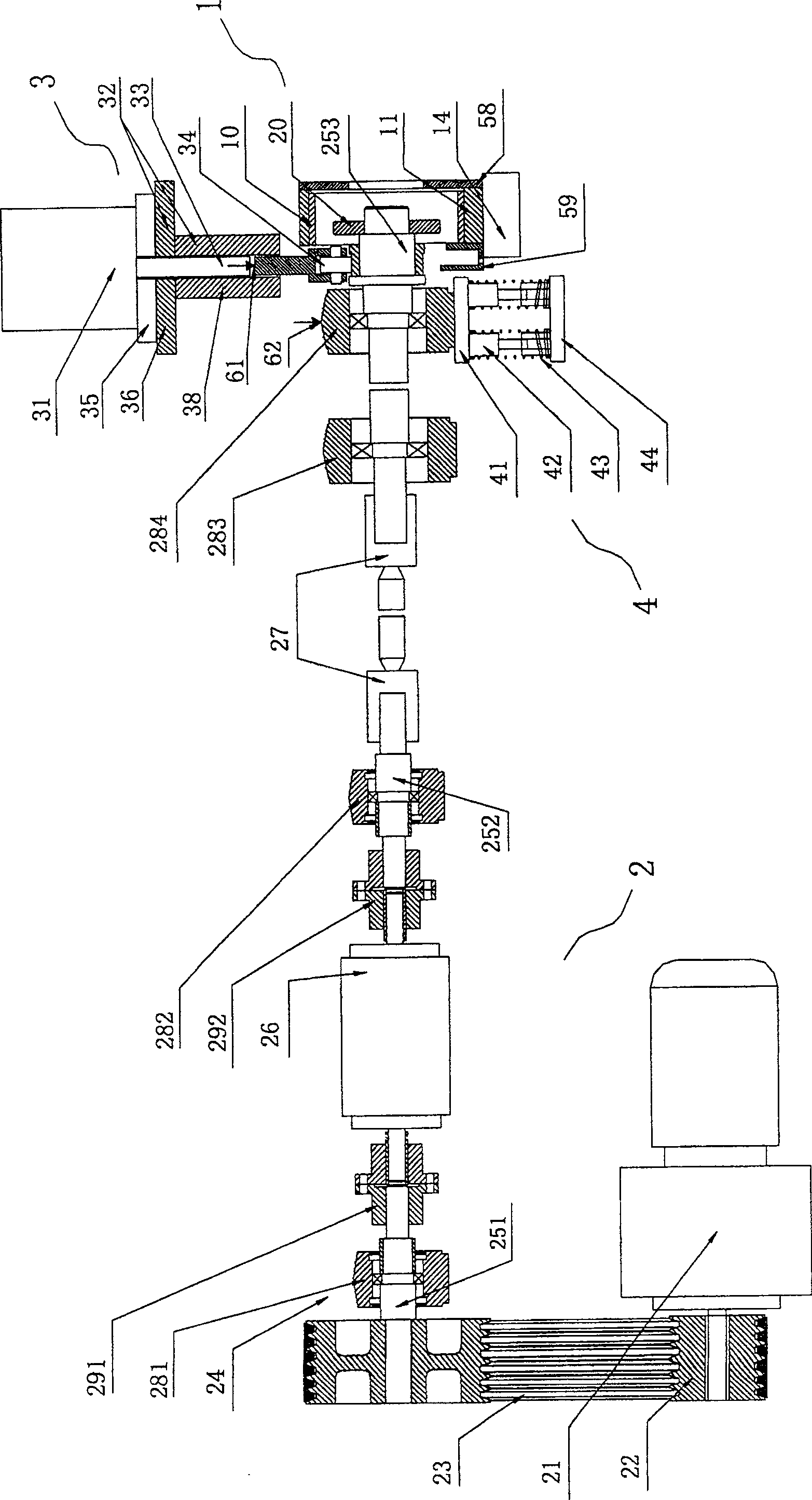

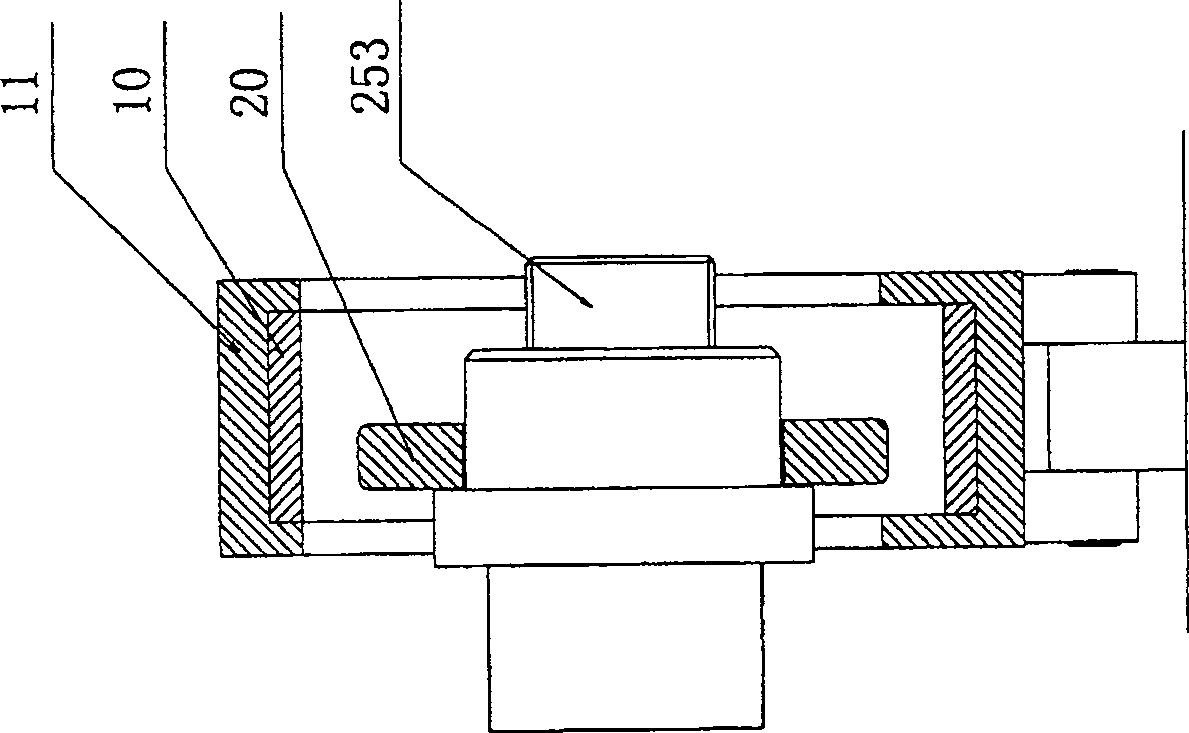

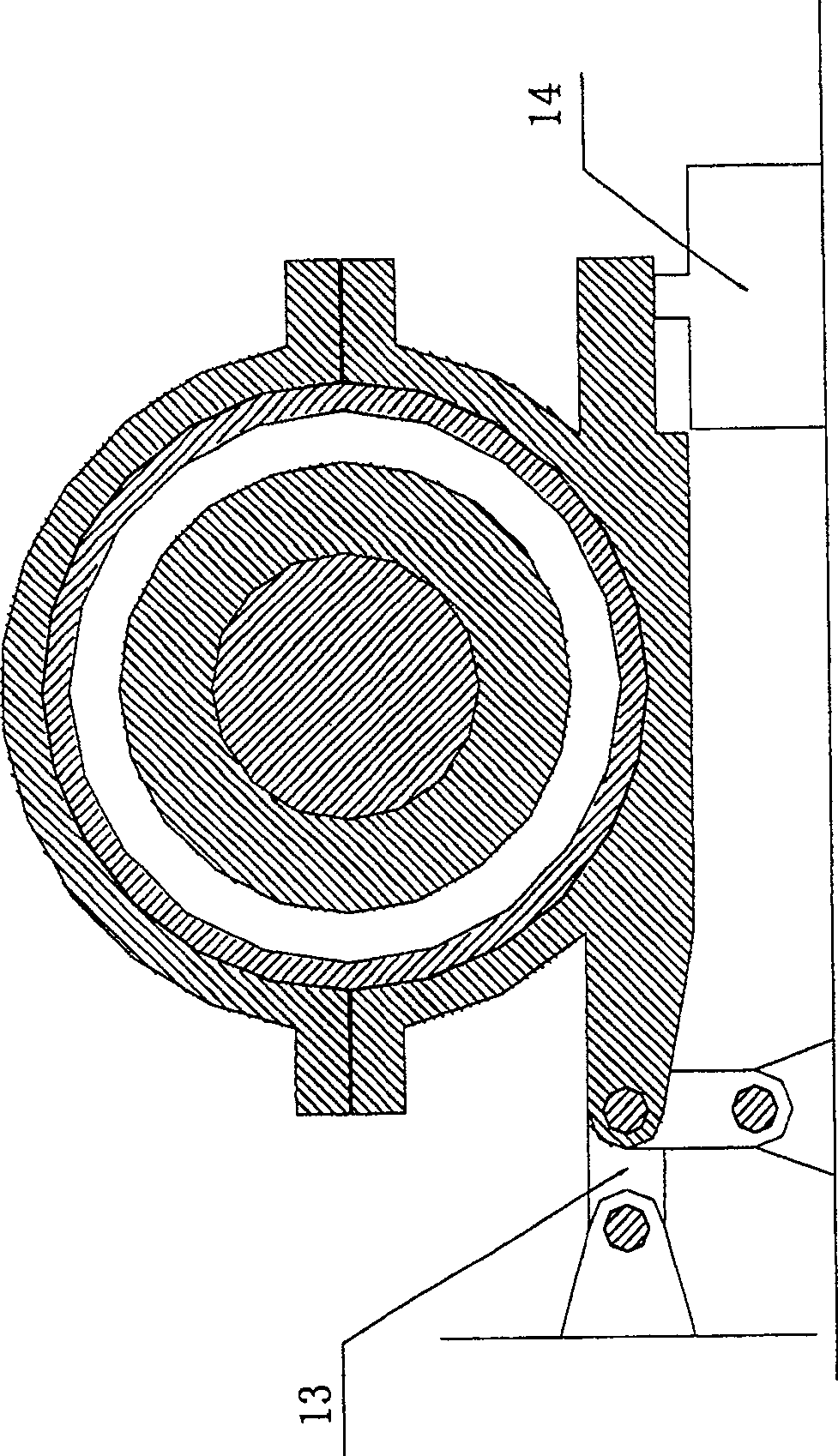

[0041]As shown in the figure, the oil drilling rod and pipe impact sliding wear test machine proposed by the present invention includes a clamping system 1, a transmission system 2 and an excitation system 3, wherein the clamping system 1 fixedly clamps the first test piece, One end of the transmission system 2 is equipped with a second test piece corresponding to the first test piece, the transmission system 2 drives the second test piece to rotate around the axis, and the vibration excitation system 3 is directed toward the second test piece. A radial impact force is provided to drive the second test piece to impact the first test piece fixed on the clamping system 1 while rotating, and transmit the torque to the second test piece through friction.

[0042] In a specific embodiment of the present invention, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com