Dual heating mode flash sintering method combining current heating with radiant heating

A radiation heating and rapid sintering technology, which is applied in the field of dual heating mode rapid sintering of current heating combined with radiation heating, can solve the problems of high energy consumption, difficulty in obtaining dense materials, long sintering time, etc., and achieves wide application and large-scale practical application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

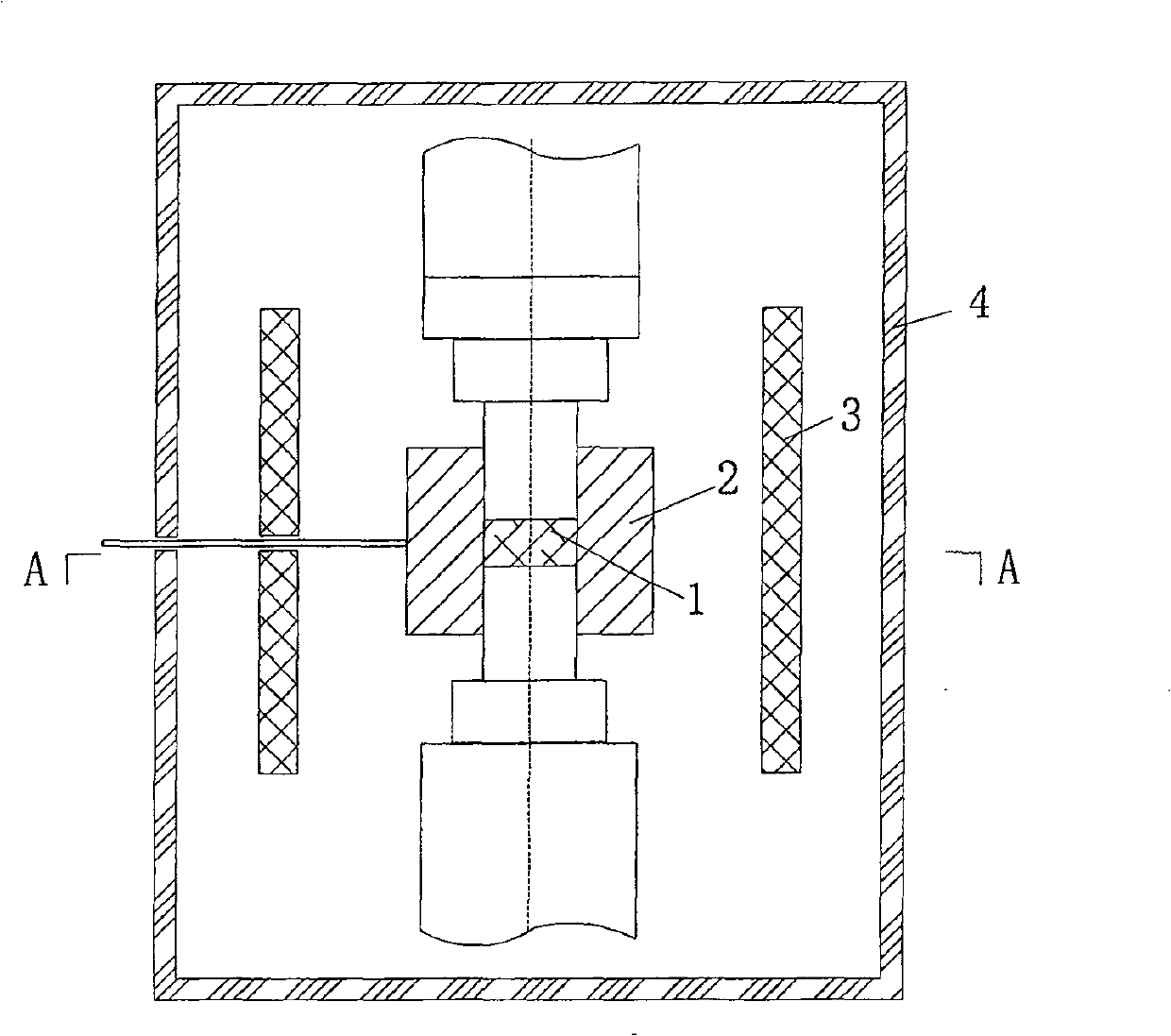

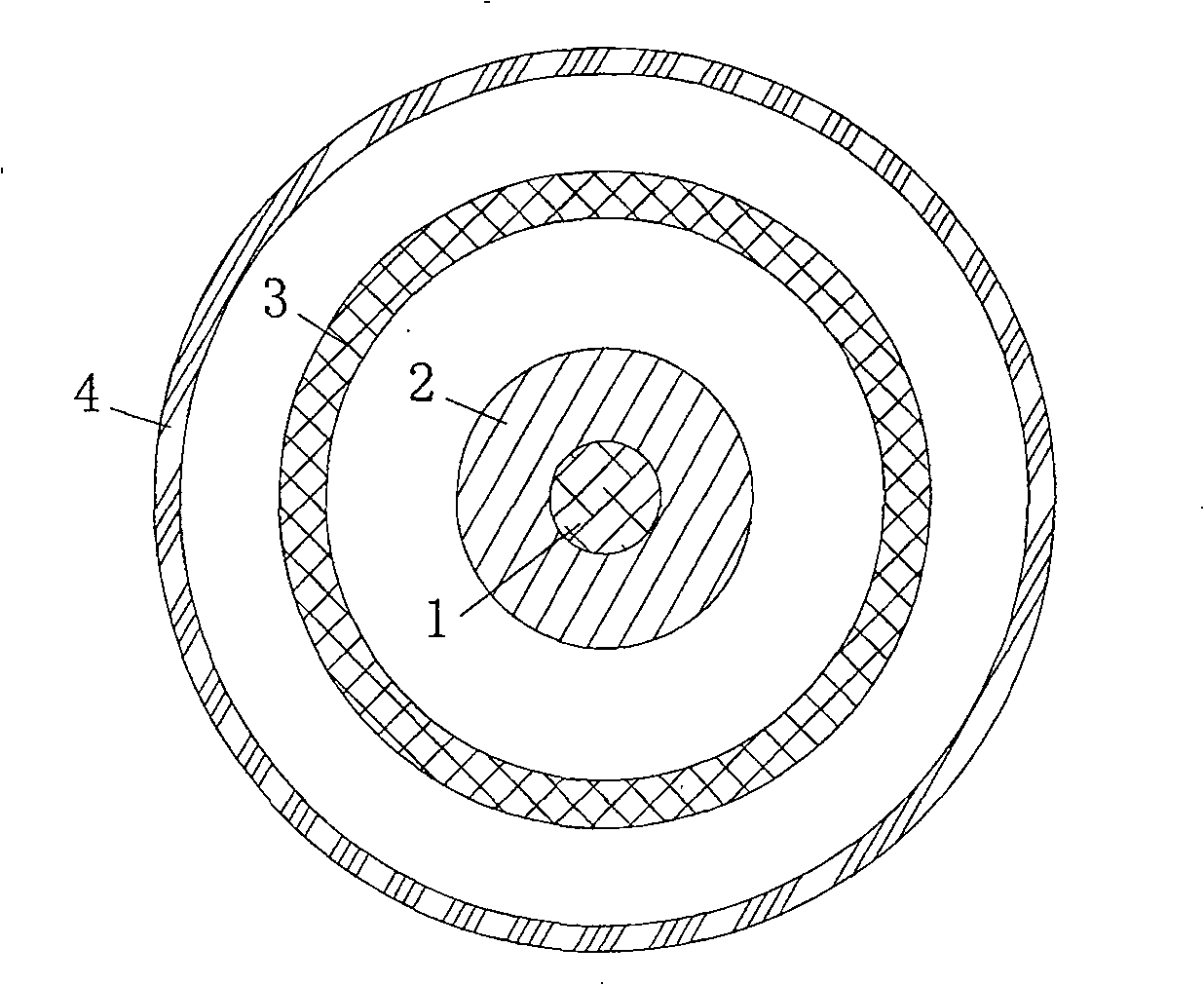

[0022] A dual heating mode rapid sintering method of current heating combined with radiation heating, 1. First, in the current sintering equipment, a radiation heating device is configured according to the current heating power supply power and radiation heating power supply power ratio of 5:1 (such as figure 1 , figure 2 shown); the installation position of the radiation heating heating element 3 of the radiation heating device is between the outer side of the mold 2 and the cavity wall 4 of the current sintering equipment, and 10 layers of high temperature are set between the radiation heating heating element and the cavity wall of the current sintering equipment The heat insulation layer and the high temperature heat insulation layer are made of carbon fiber felt; the height of the radiation heating element matches the height of the mold at a ratio of 1:2, the radiation heating element is square, and the radiation heating device has an independent power supply and temperatu...

Embodiment 2

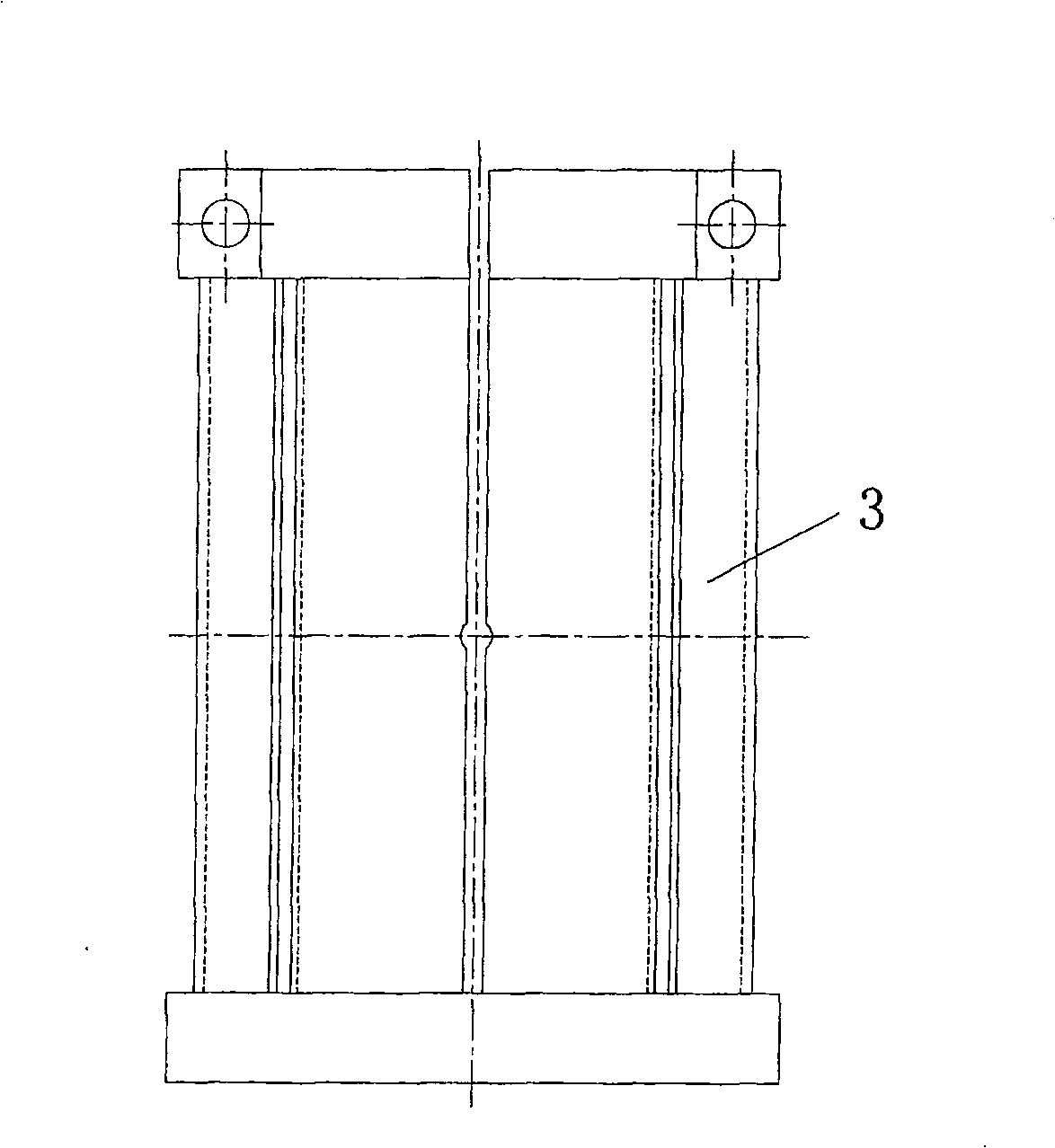

[0025] A double heating mode rapid sintering method of current heating combined with radiation heating, 1. First, in the current sintering equipment, a radiation heating device is configured according to the current heating power supply power and the radiation heating power supply power ratio of 20:1 (such as figure 1 , figure 2 , image 3 , Figure 4 shown); the installation position of the radiation heating heating element 3 of the radiation heating device is between the outer side of the mold 2 and the cavity wall 4 of the current sintering equipment, and four layers of high temperature are set between the radiation heating heating element and the cavity wall of the current sintering equipment The heat insulation layer and the high temperature heat insulation layer are made of carbon fiber felt; the height of the radiation heating element matches the height of the mold at a ratio of 1:1, the radiation heating element is cylindrical, and the radiation heating device has an...

Embodiment 3

[0029] A dual heating mode rapid sintering method of current heating combined with radiation heating, 1. Firstly, in the current sintering equipment, a radiation heating device (such as figure 1 , figure 2 shown); the installation position of the radiation heating heating element 3 of the radiation heating device is located between the outer side of the mold 2 and the cavity wall 4 of the current sintering equipment, and a layer of high temperature is set between the radiation heating heating element and the cavity wall of the current sintering equipment The heat insulation layer and the high temperature heat insulation layer are made of carbon fiber felt; the height of the radiation heating element matches the height of the mold at a ratio of 3:2, the radiation heating element is distributed, and the radiation heating device has an independent power supply and temperature measurement system.

[0030] 2. The Al-Mg alloy (sample 1) was prepared by the rapid sintering method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com