Device for testing deflagrability of condensed fire detonator under condition of high termerature and high pressure

A test device, high temperature and high pressure technology, applied in the direction of measuring device, fuel oil test, chemical analysis by combustion, etc., can solve the problems of inconvenient temperature environment, small size of the closed explosive device, difficulty in meeting the requirements of deflagration test, etc., and achieve the device structure Simple, convenient experimental operation, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

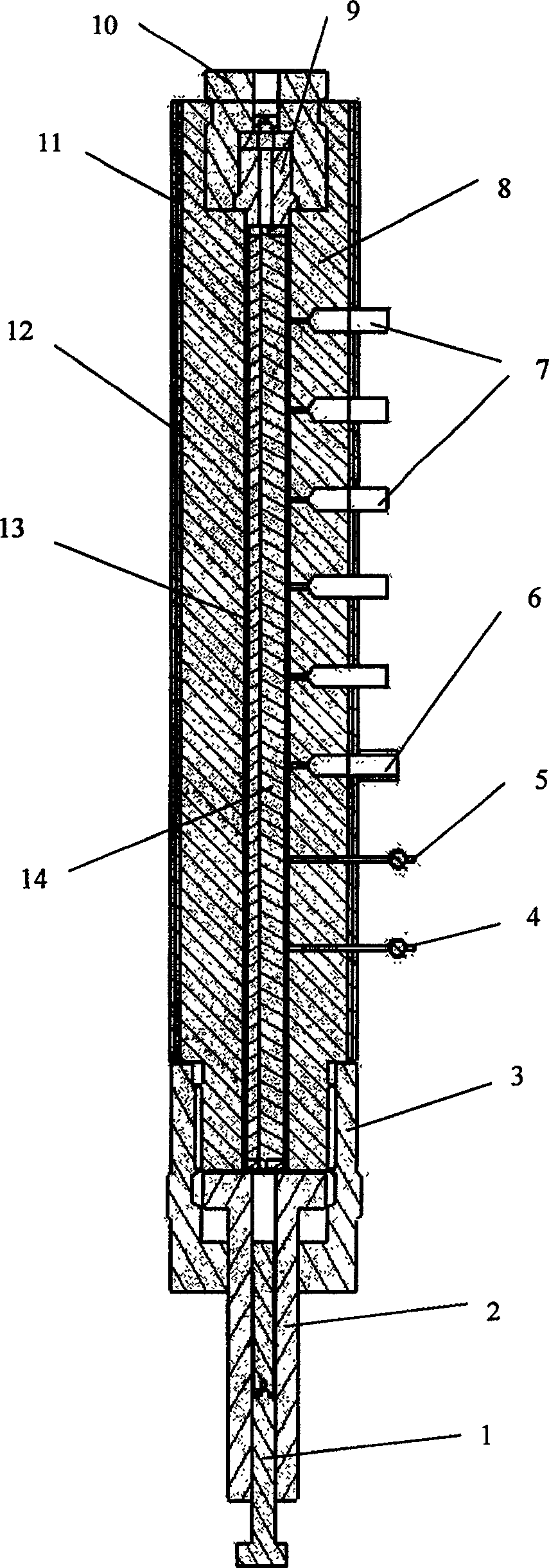

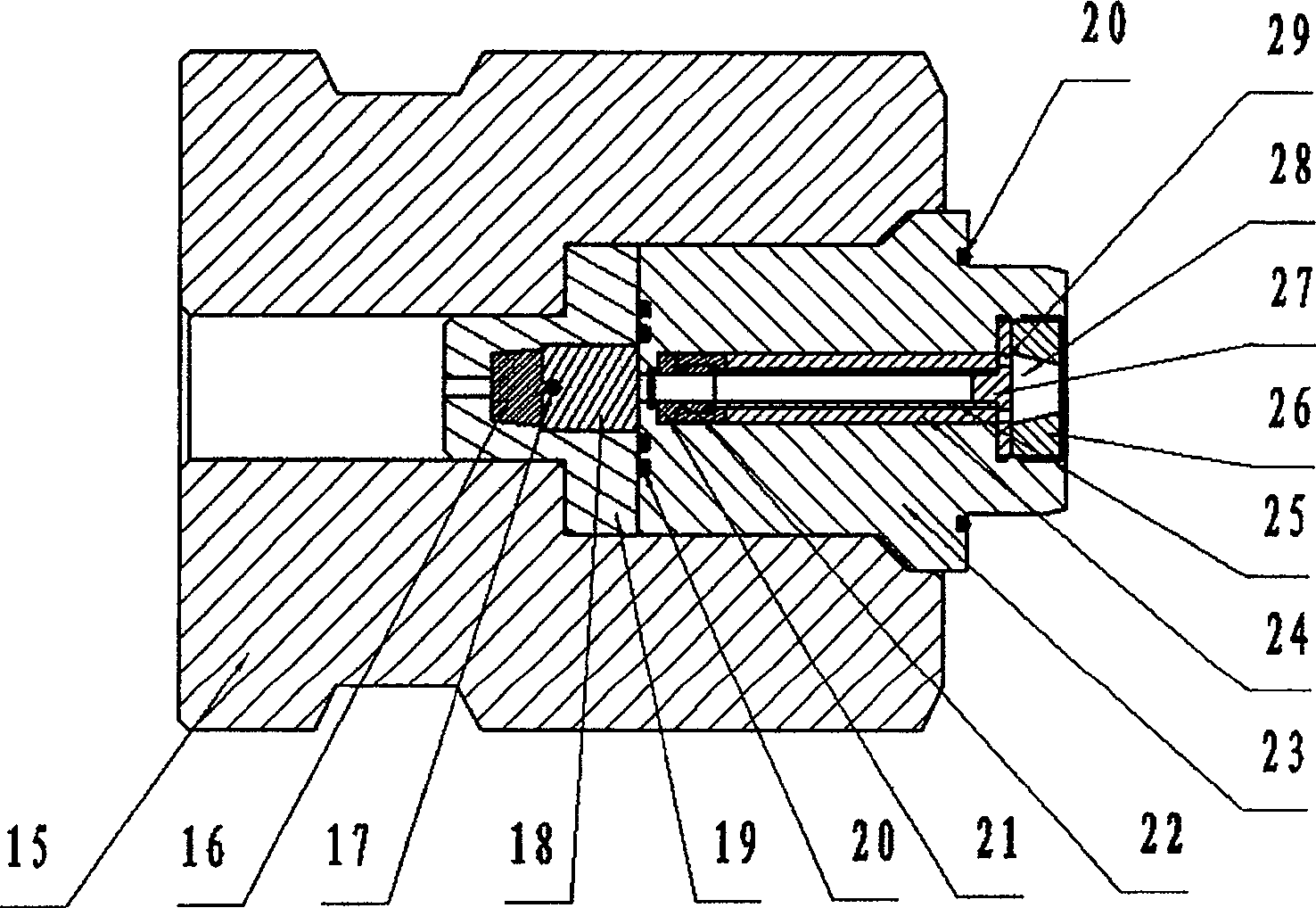

[0015] Embodiment 1: choose a high-pressure vessel with a length of 3 meters, which is a thick-walled cylinder in structure, with an outer diameter of 200 millimeters and an inner diameter of 50 millimeters. The material must have certain strength and certain toughness. In the present embodiment, it is 60Si2CrVA steel. Such a high-pressure experimental vessel can withstand a pressure of 300MPa. Make an experimental cylinder with a length of 2.8 meters and a diameter of 49.5 mm. The material of the experimental cylinder is 35CrMo, and a groove is made on the cylinder. The width of the groove is 6 mm and the depth is 30 mm. This slot is used to hold condensed explosives. A heating chip with a power of 5000W / m is placed outside the thick-walled cylinder to heat the thick-walled cylinder. The heating sheet is wrapped with asbestos cloth as a heat insulation layer to reduce heat dissipation. Drill a small hole with a diameter of 5 mm every 200 mm on the side busbar of the thick-...

Embodiment 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the photodiodes placed on the small holes at different positions in Embodiment 1 are replaced with thermocouples. And other parts are identical with embodiment 1.

[0022] In this embodiment, when the deflagration front of the condensed explosive arrives, the thermocouple can measure the temperature signal due to the heat release from the chemical reaction of the explosive. By calculating the arrival time of temperature signals of thermocouples at different positions, the deflagration velocity of condensed explosive can be calculated.

Embodiment 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the photodiodes placed on the small holes at different positions in Embodiment 1 are replaced with metal probes. And other parts are identical with embodiment 1.

[0024] In this embodiment, when the deflagration front of the condensed propellant and explosive arrives, due to the chemical reaction of the propellant and explosive, the reaction product of the propellant and explosive is ionized and conductive, so that the metal probe can detect the ionization and conduction signal of the reaction product of the propellant and explosive. The deflagration velocity of the condensed explosive can be calculated by calculating the arrival time of the conductive signal of the metal probe at different positions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com