CAN bus line communication detecting method for aluminum cell control system

A technology of CAN bus and detection method, which is applied in the field of communication detection, can solve problems such as affecting electrolysis production, completion of technical indicators and improvement of efficiency, separation of electrolytic cells from automatic control and monitoring environment, and great influence of line impedance with temperature changes, etc. Achieve the effect of solving the difficulty of judging and processing, shortening the maintenance time and improving the maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

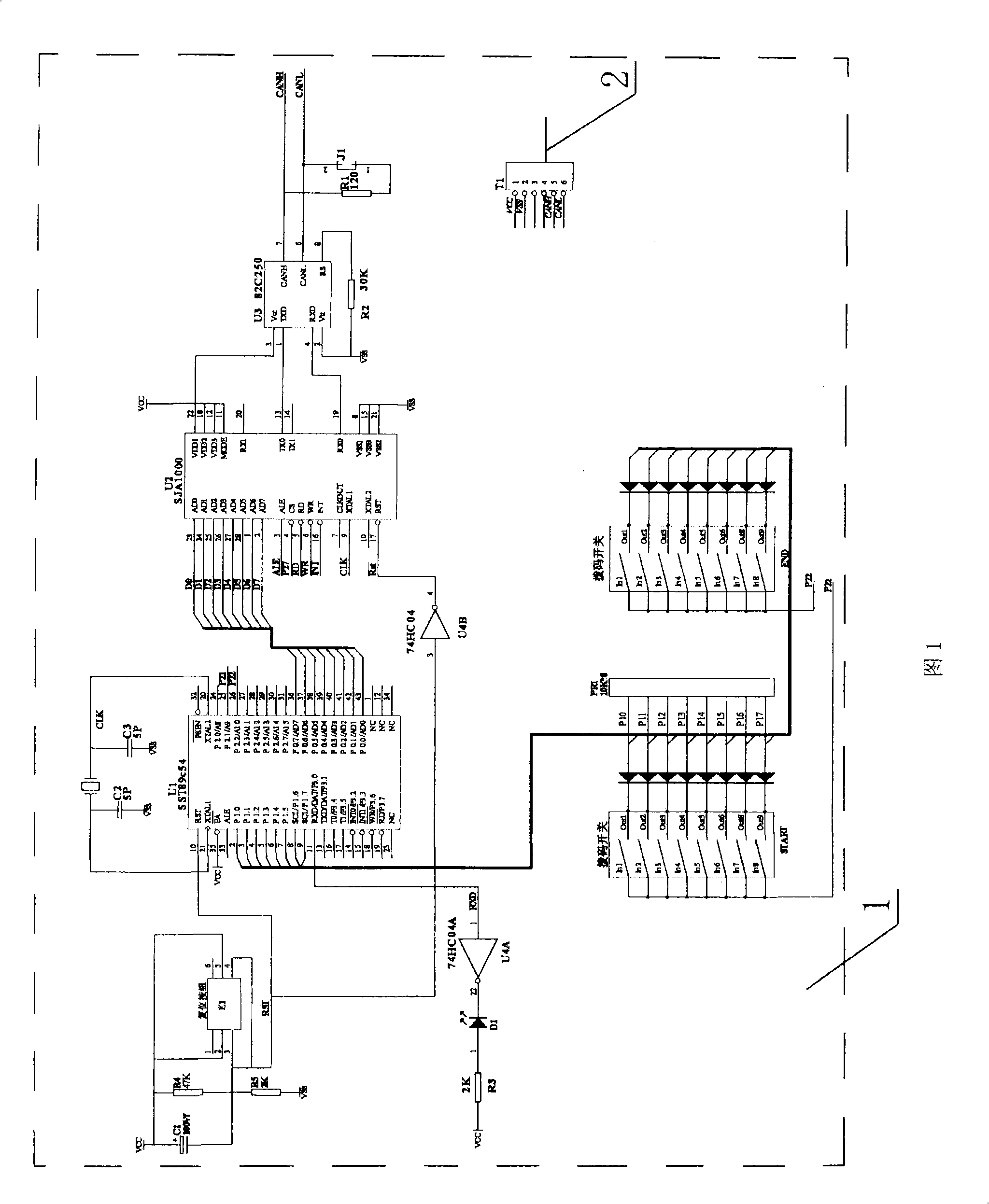

Image

Examples

Embodiment 1

[0023] The detection function of the CAN bus communication detection method of the aluminum electrolytic tank control system of the present invention is realized by the method of combining software and hardware through the CAN bus communication detector 1 of the aluminum electrolytic tank control system. Through software programming, read the slot number of the selected slot control machine in a certain interval, and carry out cyclic detection of its CAN bus communication status, output a pulse signal with a frequency of 2Hz when the communication is normal, and use this signal to drive the CAN bus communication status indicator The circuit judges whether the CAN bus communication of the detected slot control machine is normal or not according to the on and off of the indicator light, and finally achieves the purpose of rapid detection and timely maintenance. Write the CAN bus communication detection program code into the ROM memory of U1. After judging the communication status...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com