Non-symmetric structure grid velocity compensation method and velocity compensation-type bending coplane waveguide

An asymmetric structure, speed compensation technology, applied in the microwave field, can solve problems such as cost increase and volume integration reduction, and achieve the effect of reducing process and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

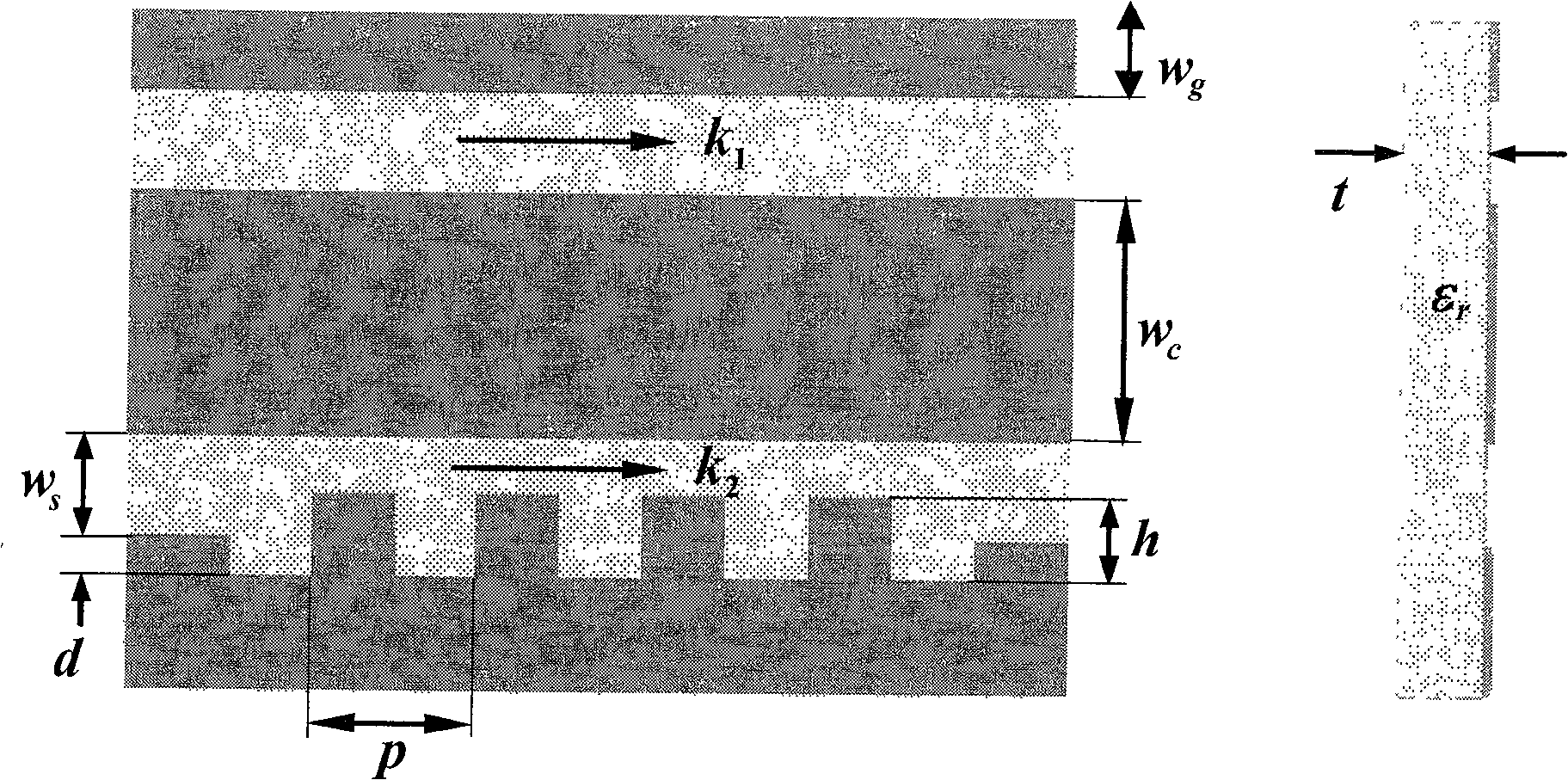

[0037] Embodiment 1: as figure 1 as shown, figure 1 The structure and parameters of the coplanar waveguide grating structure are given. Different coplanar waveguide grating structures can be obtained by changing its structural parameters. Depend on figure 1 It can be seen that k 1 and k 2 are the propagation constants of the electromagnetic wave on the non-grid structure and the grid structure, respectively. In order to prove the change of the grid structure to the propagation speed of electromagnetic waves and understand the effect of different structures, the simulation software is used to calculate the k 2 k 1 ratio, as shown in Table 1. The specific structure is set as follows: w c = 0.25mm, w g = 1 mm, w s = 0.1mm, t = 0.0625mm, ε r =12.9, Z c =50Ω. Among them, Z c is the characteristic impedance of the coplanar waveguide. It can be seen from the table that k 2 / k 1 Both are greater than 1, indicating that the grid structure does have a slow wave effect. ...

Embodiment 2

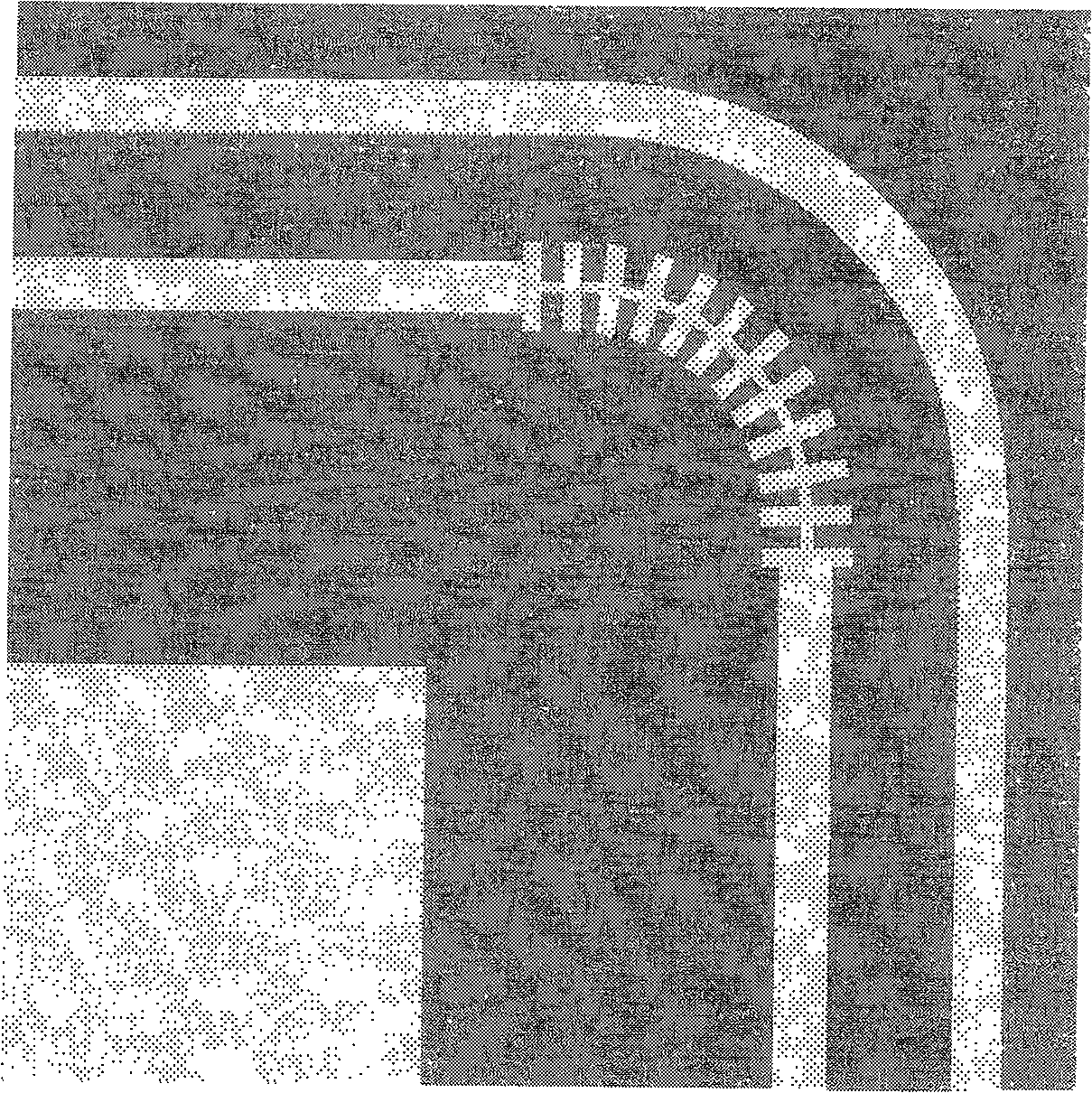

[0044] Embodiment 2: as figure 2 As shown, a rectangular grid velocity-compensated curved coplanar waveguide.

[0045] When the grid structure in Table 1 is specifically applied to a discontinuous coplanar waveguide, the slot with a shorter path on the coplanar waveguide should be set as a grid structure. Taking the 90° curved coplanar waveguide as an example to illustrate the specific implementation, since the path length of the outer slot is greater than that of the inner slot, the inner slot should be made into a grid structure. figure 2 The structure and parameters of the 90° curved coplanar waveguide grating structure are given.

[0046] Formulas (1) and (2) give the calculation formulas for determining the grid length (the parameters in the formula are shown in Table 1):

[0047] k 2 S=k 1 (S+ΔS)(1)

[0048] S = ΔS k 2 k ...

Embodiment 3

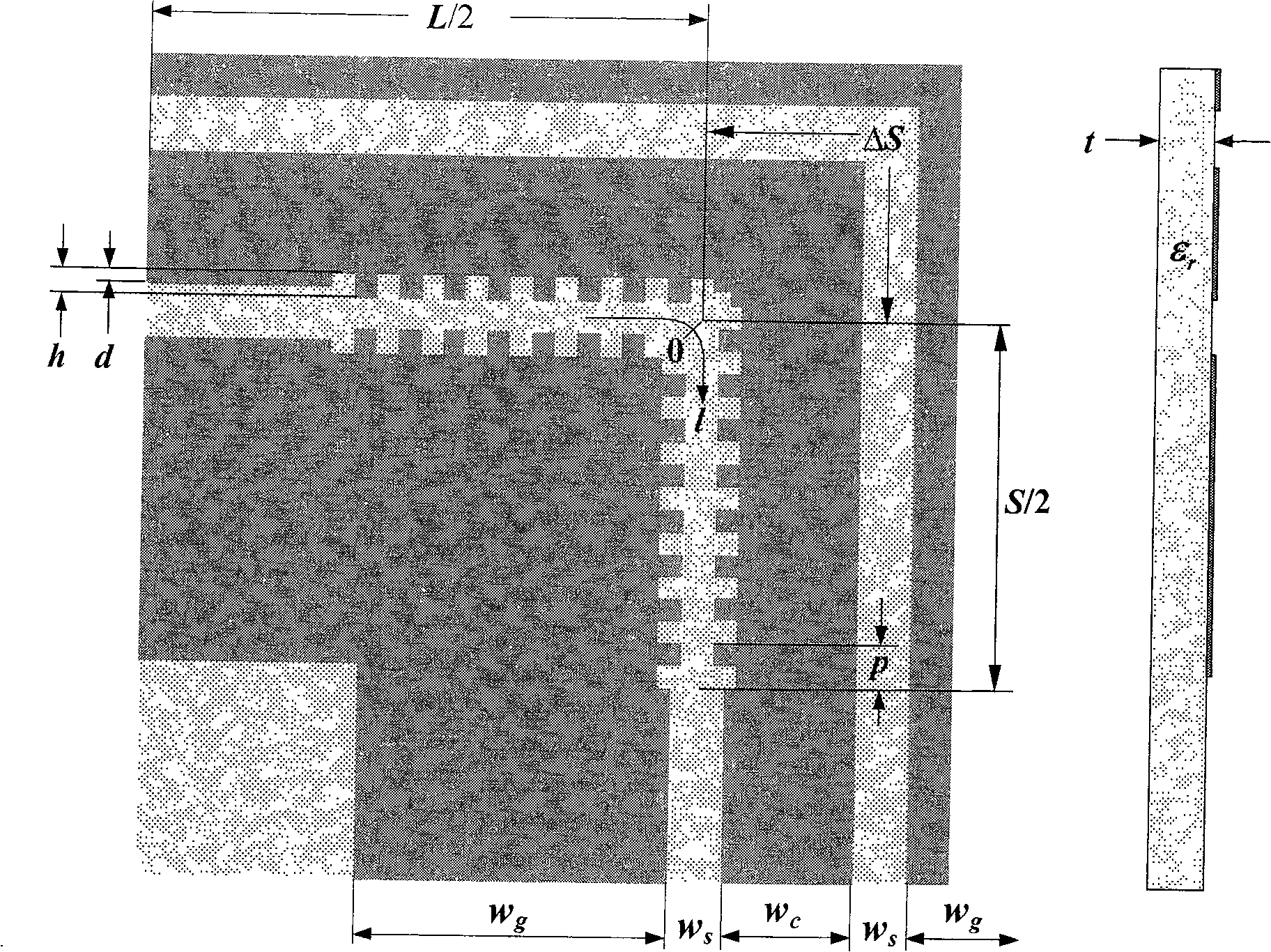

[0053] Embodiment 3: as image 3 As shown, the deformed grid velocity compensation type 90° arc-shaped curved coplanar waveguide structure.

[0054] Since the structure is arc-shaped at the bend, the grid structure changes accordingly, forming a deformed grid.

[0055] Numerical calculation results

[0056] The 90° curved coplanar waveguides with grid structure types A1, C3, D2 and D3 are analyzed and calculated by simulation software, and some numerical calculation results are obtained. The specific structural settings are as follows: L=7.65mm; C3: S=4.7mm; D2: S=3.1mm; D3: S=4.925. Other structural parameters are shown in Table 1. Figure 8 , Figure 9 The S of these four structures are given respectively 11 , S 21 The magnitude of the parameter varies with frequency. Depend on Figure 8 , Figure 9 It can be seen that the reflection coefficient S 11 reduced, the transfer coefficient S 21 It increases in the higher frequency region, indicating that the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com