Photoresist coating system

A glue coating and lithography technology, applied in the field of photoresist coating systems, can solve the problems of pipeline blockage, failure to spray, and lengthened production cycle, so as to reduce the rework rate and reject rate, reduce production costs, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] During the coating process of photoresist, the amount of photoresist sprayed may deviate easily due to air bubbles, pipeline aging or mechanical failure. However, the existing photoresist coating system has no means of monitoring the spraying results, and only relies on the photoresist after coating. Sampling measurement of the thickness of the thin layer of resist to verify whether the spraying amount of photoresist is normal, and the deviation of the actual spraying amount cannot be found in time, resulting in the difference in the spraying amount of photoresist (or the thickness of the thin layer of photoresist) between batches. Repeatability is not guaranteed, and the rework rate and scrap rate are also high.

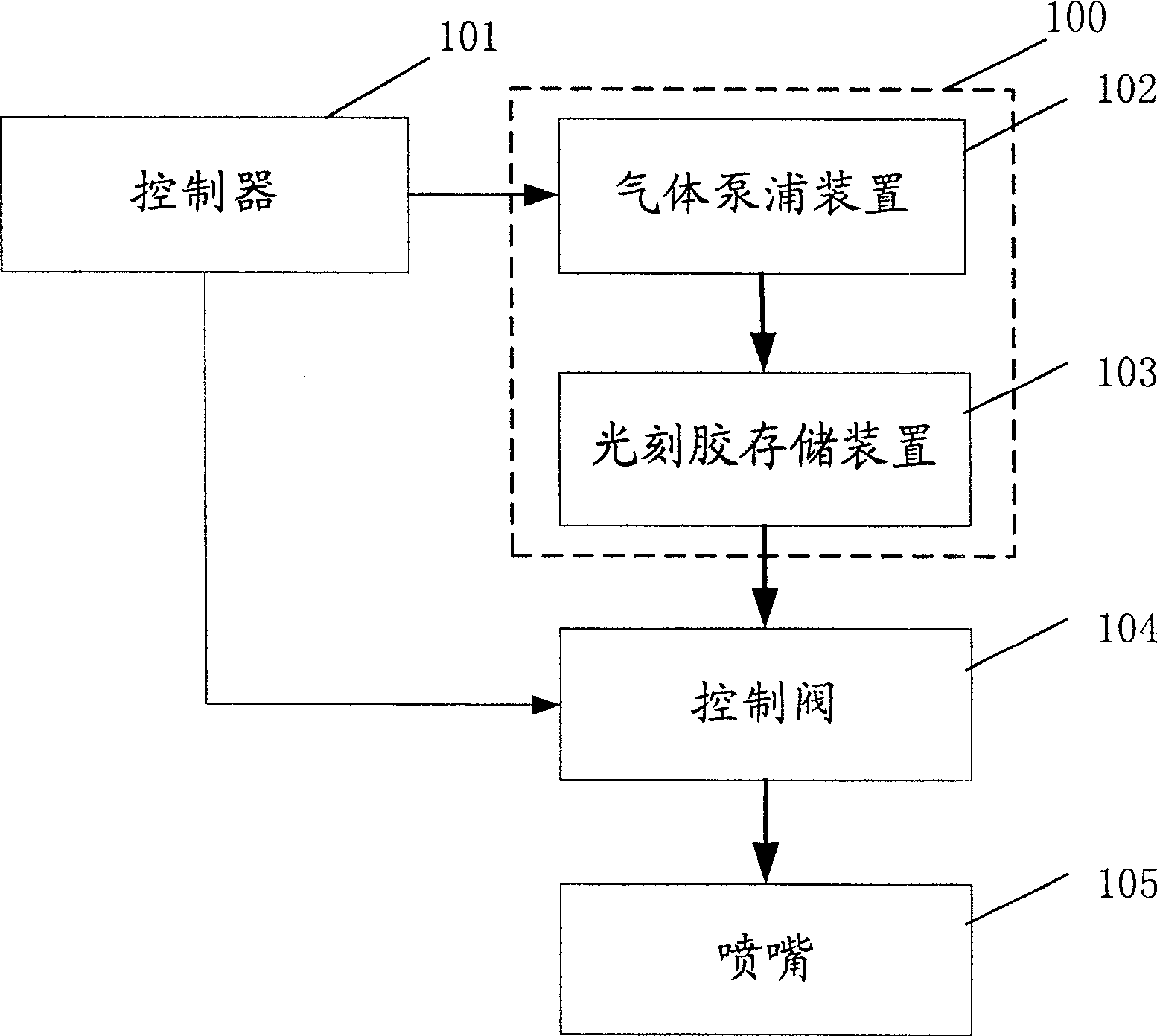

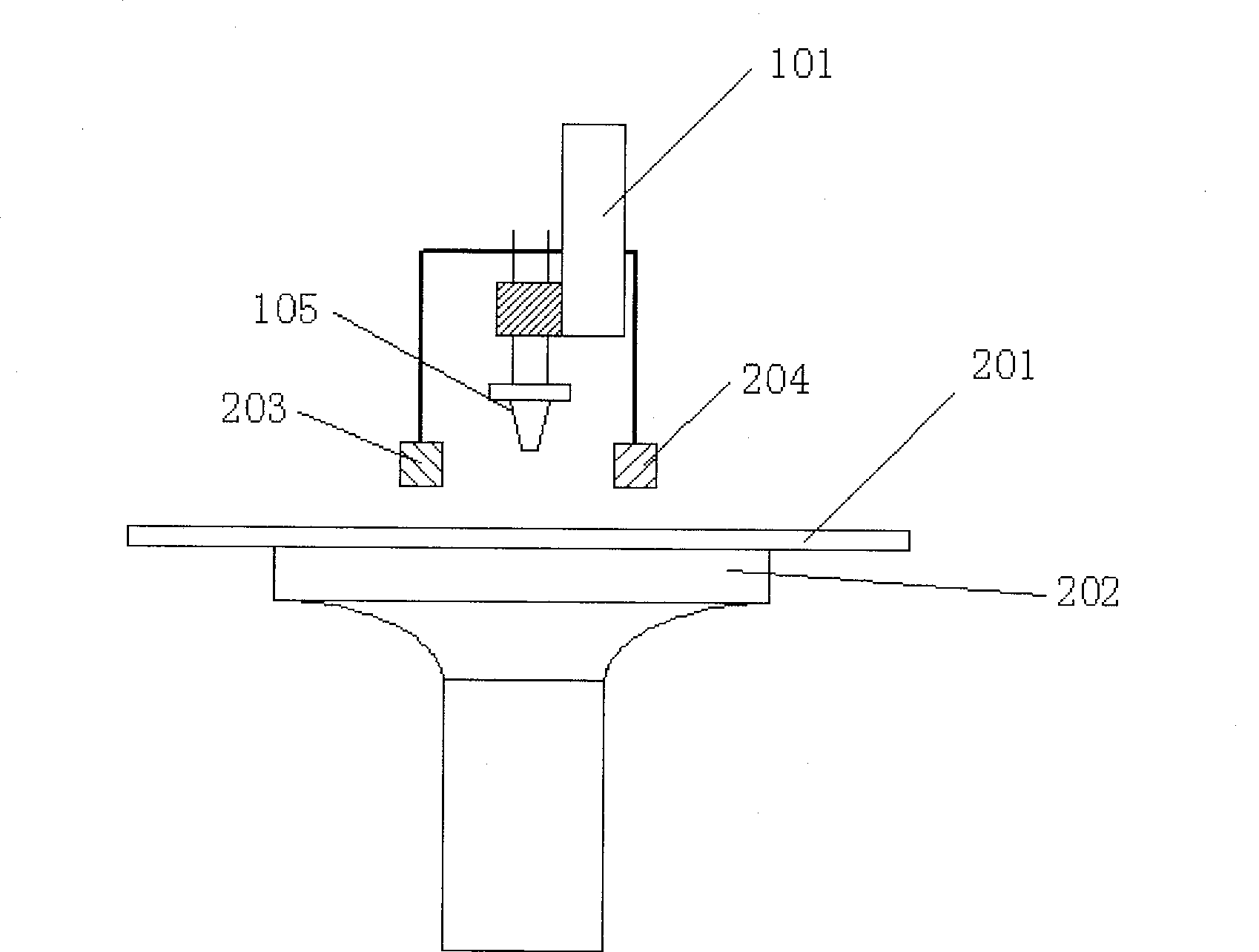

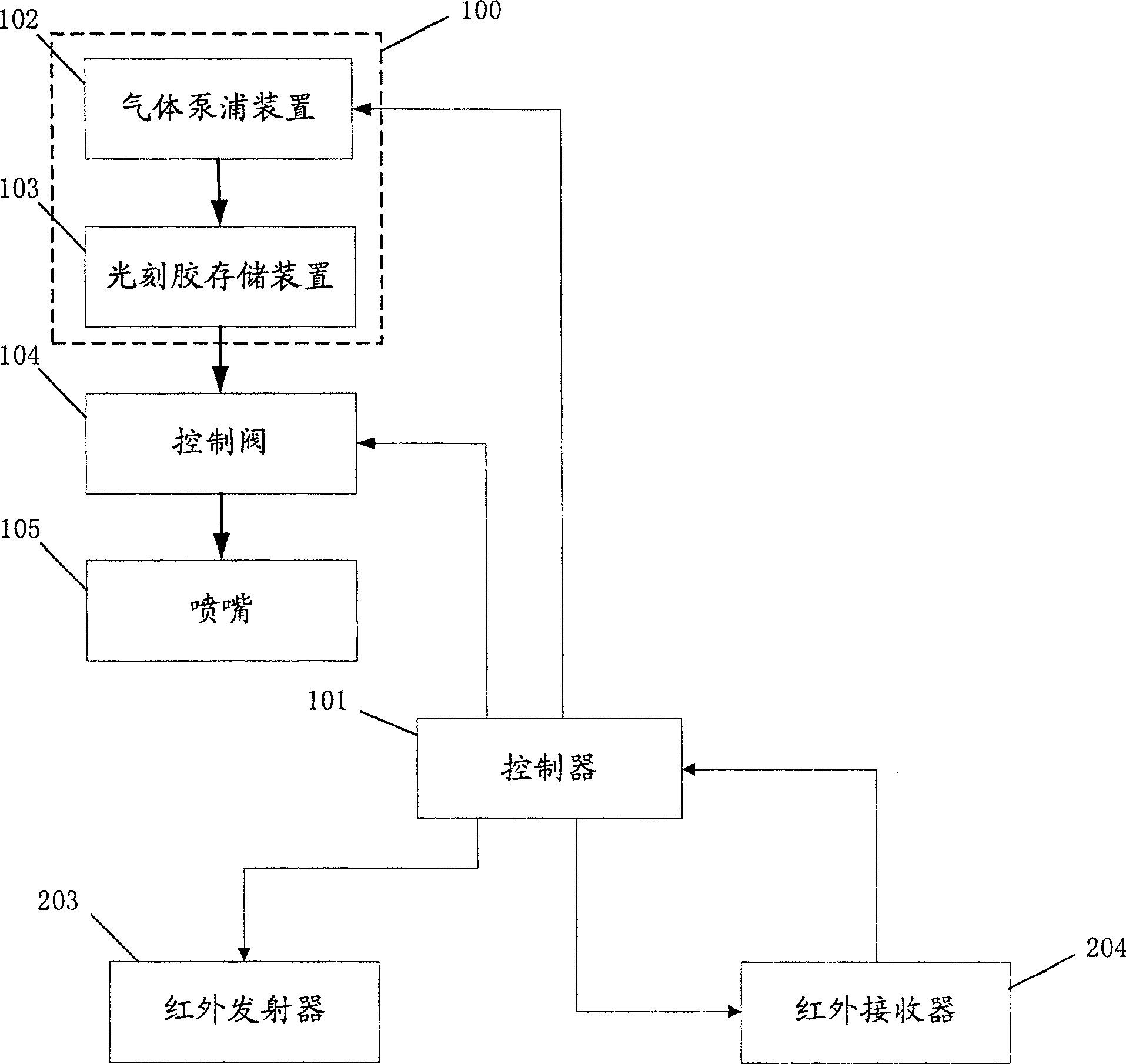

[0029] The ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com