Ash conversion method in alumina preparation

A technology of alumina and aluminum hydroxide, which is applied in alumina/aluminum hydroxide, alumina/hydroxide preparation, chemical instruments and methods, etc., can solve problems such as alumina loss, reduce energy consumption, reduce water consumption, etc. copies, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

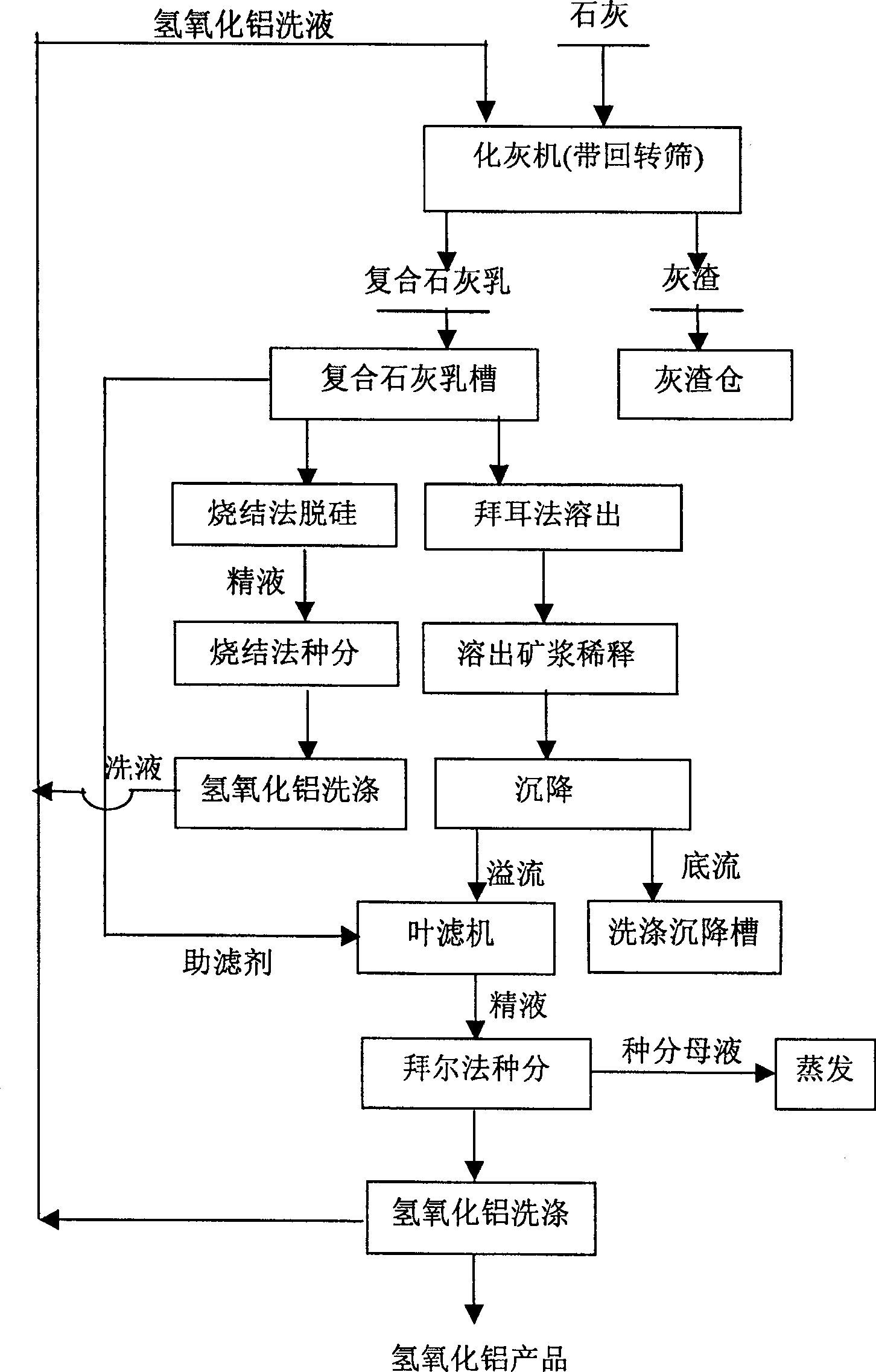

Image

Examples

example 1

[0014] Measure 100ml of the sintering method aluminum hydroxide washing solution, weigh 50g of dry lime powder; use the aluminum hydroxide washing solution to make dry lime powder at a temperature of 40°C for 10 minutes, and carry out physical and chemical analysis on the synthesized composite milk of lime. Its physical phase includes calcium hydroxide, calcium aluminate hydrate, calcium aluminum carbonate hydrate, etc. The effective calcium content of chemical analysis is 210g / L, and the deep desilication test is carried out on the primary semen of the sintering method with an effective calcium content of 6g / L. The desiliconization temperature was 92°C and the desiliconization time was 1.5 hours, and the silicon content index reached 1060.

example 2

[0016] Measure 200ml of the sintering method aluminum hydroxide washing solution, weigh 50g of dry lime powder, use the aluminum hydroxide washing solution at a temperature of 40°C to make dry lime powder for 30 minutes, and carry out physical and chemical analysis on the synthesized composite milk of lime. Its physical phase includes calcium hydroxide, calcium aluminate hydrate, calcium aluminum carbonate hydrate, etc. The effective calcium content of chemical analysis is 186g / L, and the deep desiliconization test is carried out on the sintering method with an effective calcium content of 6g / L. The desiliconization temperature was 92°C and the desiliconization time was 1.5 hours. The result was a silicon content index of 938.

example 3

[0018] Measure 300ml of the sintering method aluminum hydroxide washing solution, weigh 50g of dry lime powder, use the aluminum hydroxide washing solution at a temperature of 50°C to make dry lime powder for 10 minutes, and carry out physical and chemical analysis on the synthesized composite milk of lime. Its phases include calcium hydroxide, calcium aluminate hydrate, calcium aluminum carbonate hydrate, etc. The effective calcium content of chemical analysis is 181g / L, and the deep desiliconization test is carried out on the sintering method with an effective calcium content of 6g / L. The desiliconization temperature was 92°C, and the desiliconization time was 2.0 hours. The result was a silicon content index of 985.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com