Method of processing sewage utilizing fluidized bed technique, organism compatibility filling thereof and preparing method of filling

A fluidized bed, affinity technology, used in aerobic and anaerobic process treatment, chemical instruments and methods, sustainable biological treatment, etc., can solve the problem of low impact resistance, low removal rate, filamentous bacteria expansion, etc. problems, to achieve the effect of reducing swelling, increasing biomass, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

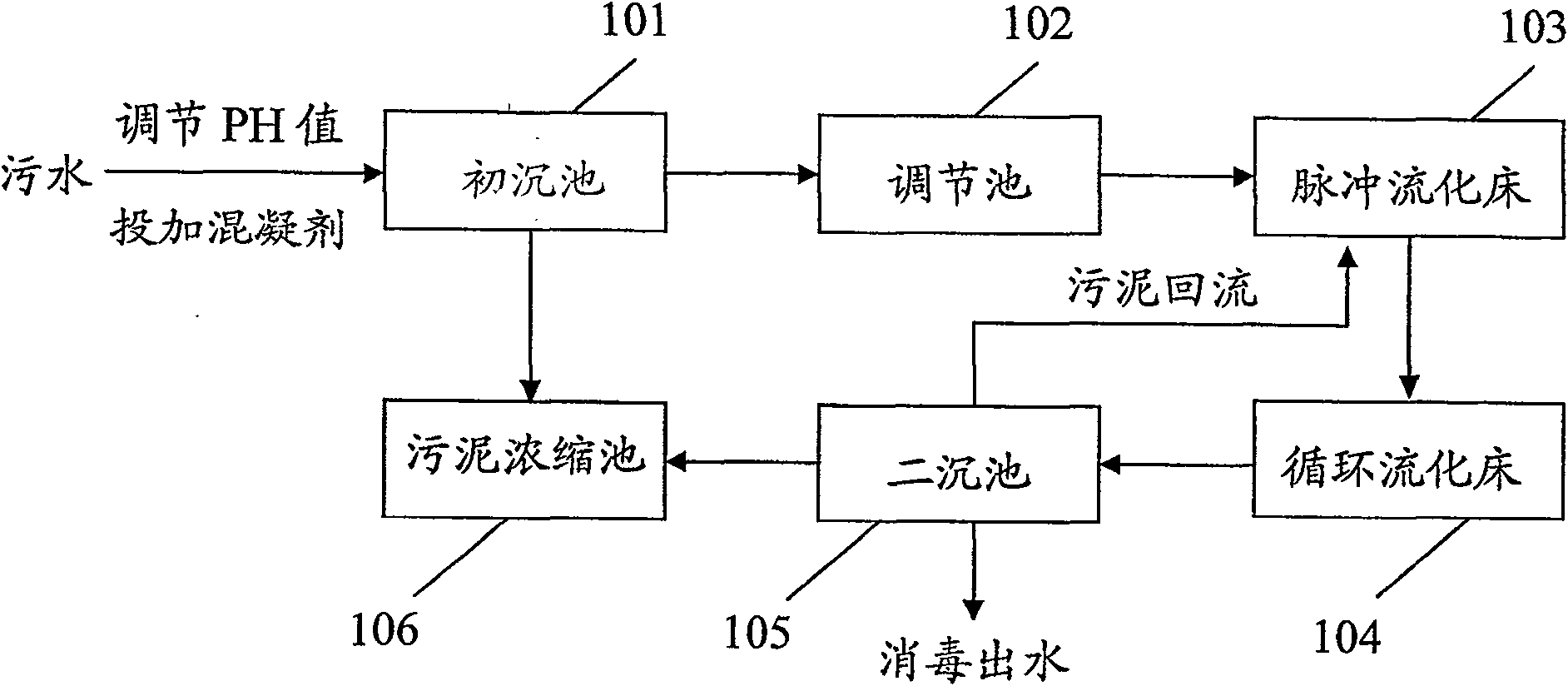

[0024] The invention provides a method for treating sewage by using a fluidized bed process, comprising the following steps:

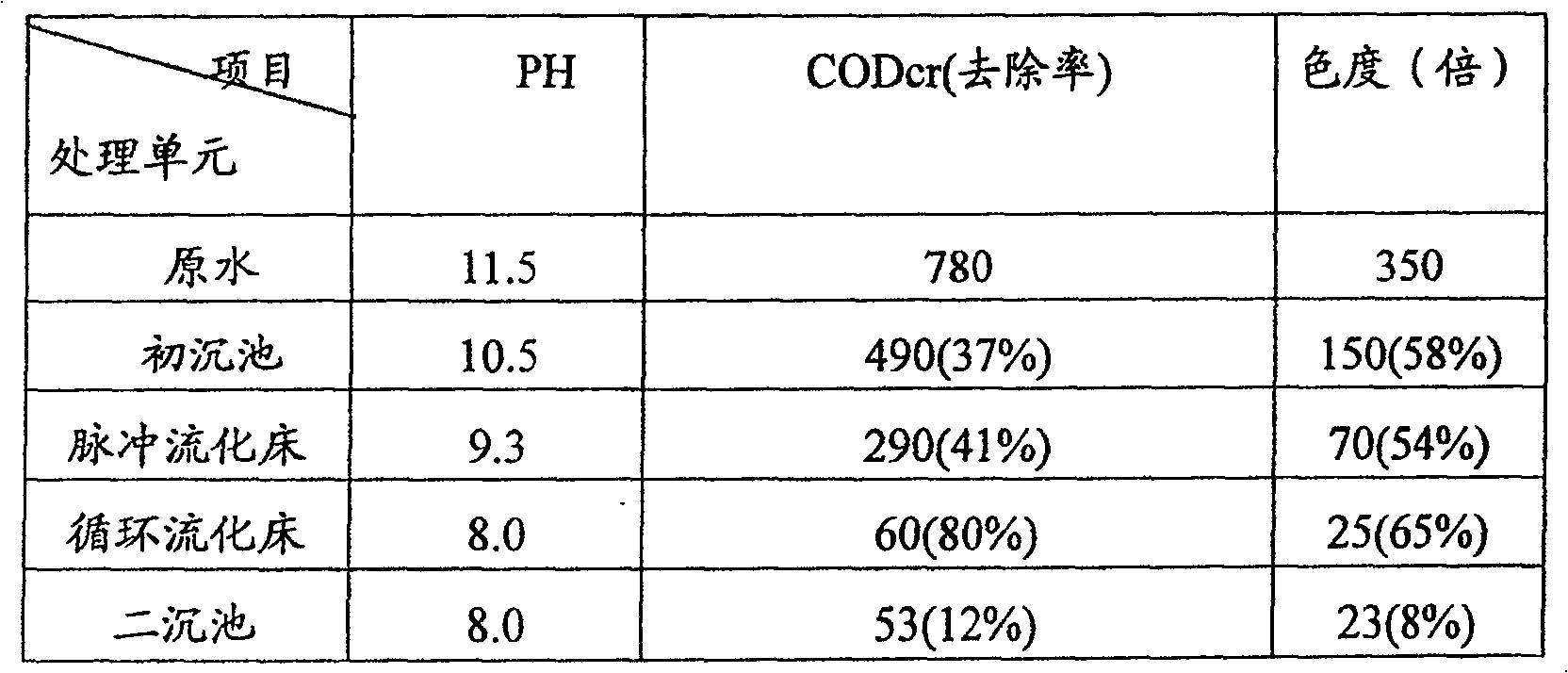

[0025] (1) Add high-efficiency bio-affinity fillers in the pulse fluidized bed and circulating fluidized bed, the sewage first enters the pulsed fluidized bed for anaerobic biochemical treatment, and then enters the circulating fluidized bed for aerobic biochemical treatment;

[0026] (1) Sewage after biochemical treatment is separated from mud and water through secondary settling tank or air flotation. The separated sewage is discharged up to the standard, and the sludge is discharged into the sludge thickening tank or returned to the anaerobic tank or aerobic tank.

[0027] (2) Pre-treatment and post-treatment can be carried out according to the water quality of the sewage. Pretreatment is mainly to remove most of the substances that are toxic to microorganisms, some refractory and high-color substances; post-treatment such as disinfection.

[0028...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com