Production of trimeric-cyanamide cyanurate fire-retardant nylon material

A technology of melamine cyanurate and flame-retardant nylon, which is applied in the field of polymer flame-retardant material preparation, can solve problems such as complex methods and high raw material costs, and achieve the effects of simple operation process, good fluidity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Mix the materials, 100 parts of nylon 6, 6 parts of melamine cyanurate, and 0.3 part of antioxidant 1010 in a high-speed mixer,

[0027] 2) Extrusion process: After the materials are mixed evenly, the materials are put into the twin-screw extruder, the extrusion temperature is 230°C, the rotation speed of the host is 480r / min, and the reaction is 1 to 2 minutes. Granules were dried in vacuum at 80°C for 8 hours. Relative density 1.123g / cm 3 , the melt flow rate is 1.61 (g / 10min), the flame retardant effect reaches UL94V-1 level, and the mechanical properties are shown in Table 3.

Embodiment 2

[0029] 1) The materials, 100 parts of nylon 6, 10 parts of melamine cyanurate, and 0.3 parts of antioxidant 1010, were mixed evenly in a high-speed mixer.

[0030] 2) Extrusion process: after the materials are mixed evenly, put the materials into the twin-screw extruder, the extrusion temperature is 225°C, the rotation speed of the host is 480r / min, react for 1 to 2 minutes, and go through stretching, cooling, cutting Granules were dried in vacuum at 100°C for 5 hours. Relative density 1.113g / cm 3 , the melt flow rate is 1.72 (g / 10min), the flame retardant effect reaches UL94V-0 level, and the mechanical properties are shown in Table 3.

Embodiment 3

[0032] 1) The materials, 100 parts of nylon 6, 16 parts of melamine cyanurate, and 0.3 parts of antioxidant 1010, were mixed evenly in a high-speed mixer.

[0033] 2) Extrusion process: After the materials are mixed evenly, the materials are put into the twin-screw extruder, the extrusion temperature is 230°C, the rotation speed of the host is 480r / min, and the reaction is 1 to 2 minutes. Granules were dried in vacuum at 100°C for 5 hours. Relative density 1.084g / cm 3 , the melt flow rate is 1.88 (g / 10min), the flame retardant effect reaches UL94V-0 level, and the mechanical properties are shown in Table 3.

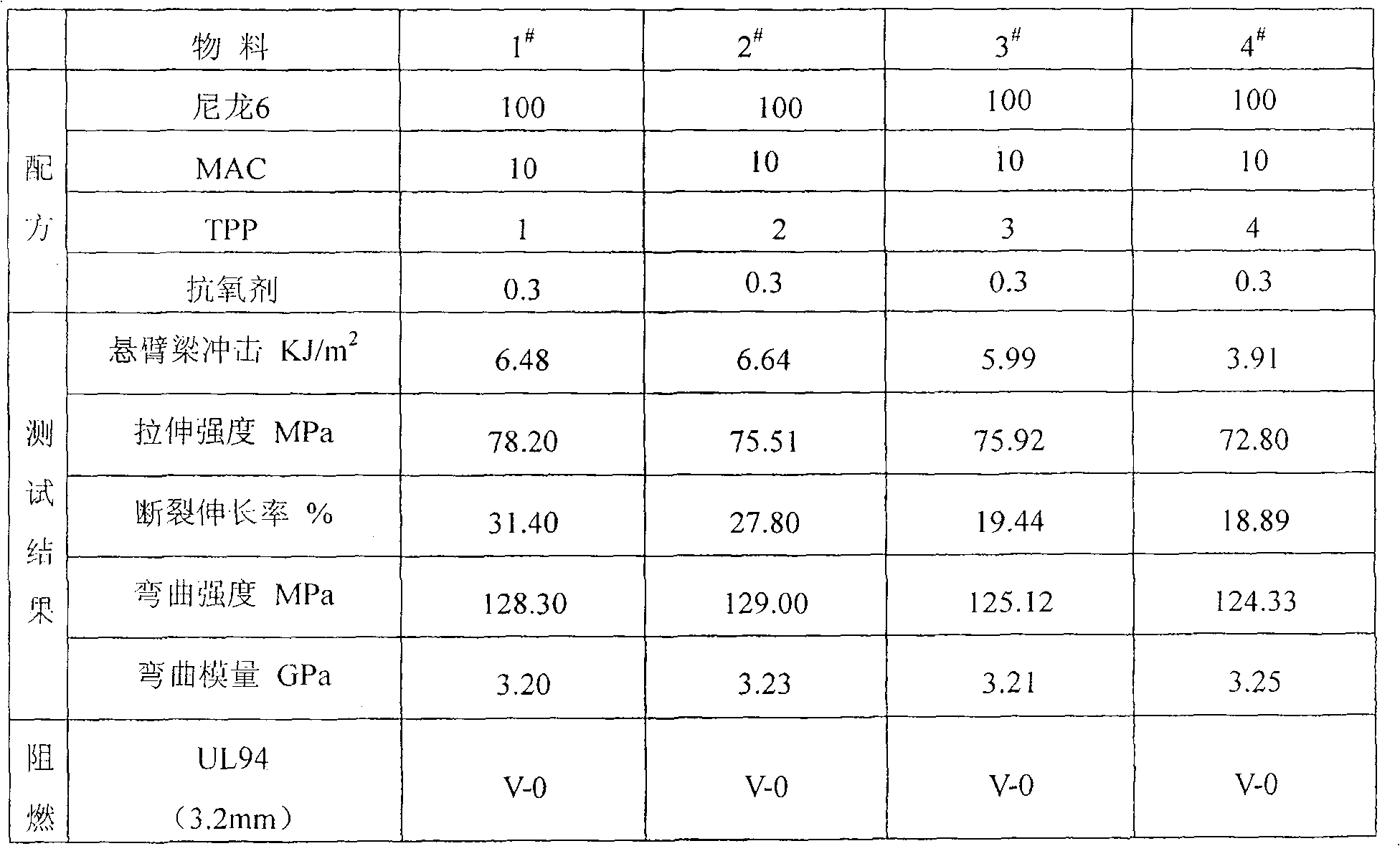

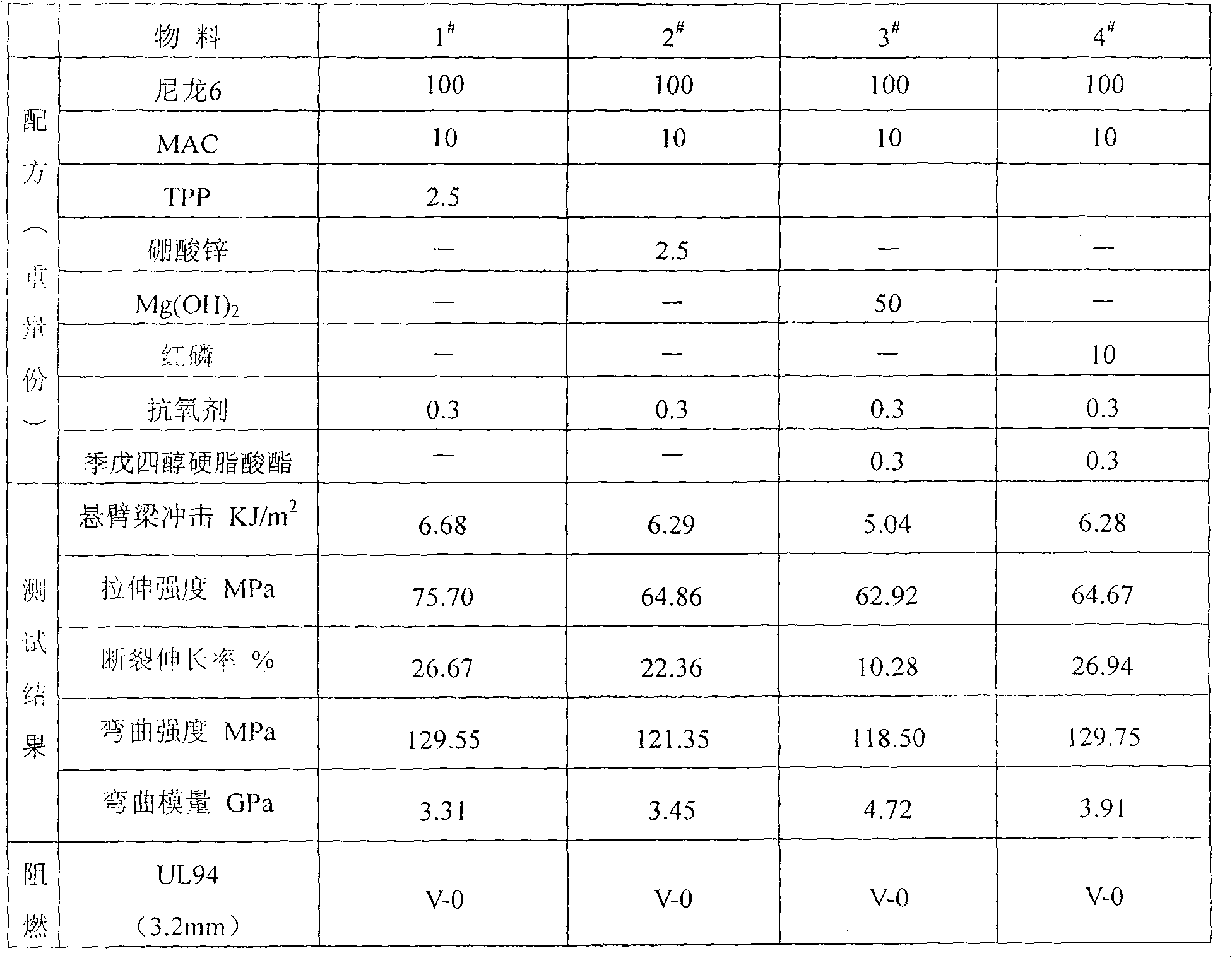

[0034] table 3

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com