Method for producing electron-level phosphoric acid

An electronic-grade phosphoric acid and phosphoric acid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve mild operating conditions, good economic benefits, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

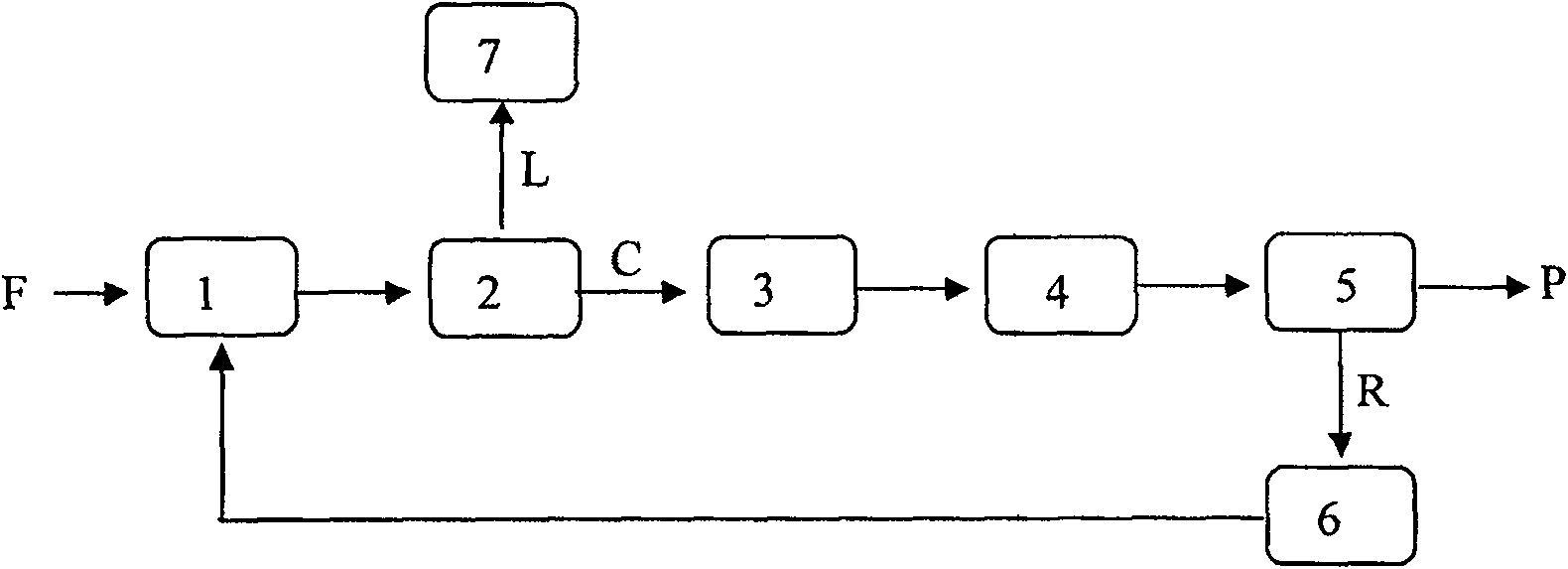

Method used

Image

Examples

preparation example Construction

[0024] Preparation of seed crystals:

[0025] Take 500g of electronic-grade phosphoric acid and add it to a 1000mL three-port boron glass crystallizer, connect it with a stirrer, a dryer, and a cooling system, rapidly cool down to ≤-25°C under stirring, and obtain seed crystals by explosive crystallization for use.

Embodiment 1

[0027] Take 600g mass ratio of 85% thermal food-grade phosphoric acid and add it to a 1000mL three-port boron glass crystallizer, connect the stirrer, drying pipe, cooling system, start stirring, the stirring rate is 400rpm, control the temperature of the material at 20 °C and add the above Prepare 90g of phosphoric acid crystals as seed crystals, then gradually cool down at a cooling rate of 4°C / h for 1h, then cool down at a rate of 2°C / h for 2h, cool to 12°C, grow crystals for 2h, and then centrifugally filter to obtain crystals for use in An appropriate amount of high-purity water or high-purity phosphoric acid solution was washed to finally obtain 415 g of phosphoric acid hemihydrate crystals, with a phosphoric acid yield of 64.22%. The test results are shown in Table 1.

[0028] Table 1 Embodiment 1 crystal product impurity content

[0029] Index Item

Impurity concentration

Index Item

Impurity concentration

Aluminum (Al)

0.5ppm

Iron (Fe...

Embodiment 2

[0034] Take 600g of 80% wet-purified phosphoric acid and add it to a 1000mL boron glass crystallizer, connect the stirrer, drying pipe, and cooling system, start stirring at a stirring rate of 400rpm, and add 120g of phosphoric acid crystals prepared above when the temperature drops to 6°C to make Seed crystals, keep the temperature for 1h, then cool down at a cooling rate of 8°C / h for 1h to -2°C, then cool down at a cooling rate of 4°C / h for 2.5h to -12°C, keep warm for 1h, and then centrifugally filter to obtain crystals with an appropriate amount After washing with high-purity water or high-purity phosphoric acid solution, 349 g of phosphoric acid hemihydrate crystals were finally obtained, and the yield of phosphoric acid was 54.25%.

[0035] Take 300g of the above-mentioned phosphoric acid hemihydrate crystal and add it to a 500mL boron glass crystallizer, add 20g of ultrapure water, connect the stirrer, drying pipe, and cooling system, start stirring, and the stirring rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com