Rare earth Dy<3+>-doped indium tungstate nano material, preparation method and application thereof

A nanomaterial, indium tungstate technology, applied in luminescent materials, chemical instruments and methods, tungsten compounds, etc., can solve the problems of poor morphology repeatability and low yield, and achieve good morphology repeatability and yield. High, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] InCl 3 (1.9 mmol), Na 2 WO 4 2H 2 O (3.0 mmol) and Dy (NO 3 ) 3 ·5H 2 O (0.1 mmol) was dissolved in a mixed solvent of n-hexane (1.0 mL) and N,N-dimethylacetamide (6.0 mL), added tetrabutylammonium bromide (TBAB, 1.0 mmol), and transferred to 20 mL reaction kettle, stir evenly initially, then add 20 μL of n-propylamine dropwise, continue to stir evenly, adjust the pH to about 7.5, then react at a constant temperature of 180°C for 12 hours, naturally cool to room temperature, centrifuge to get the solid product and successively wash with ethanol After repeated washing with cyclohexane, the rare earth Dy can be obtained by drying 3+ Doped indium tungstate nanomaterials.

Embodiment 2

[0020] will InCl 3 (1.98 mmol), Na 2 WO 4 2H 2 O (3.0 mmol) and Dy (NO 3 ) 3 ·5H 2 O (0.02 mmol) was dissolved in a mixed solvent of n-hexane (2.0 mL) and N,N-dimethylacetamide (4.0 mL), added tetrabutylammonium bromide (TBAB, 1.0 mmol), and transferred to 20 mL reaction kettle, stir evenly initially, then add 40 μL n-propylamine dropwise, continue to stir evenly, adjust the pH to about 8.5, then react at a constant temperature of 170°C for 16 hours, naturally cool to room temperature, centrifuge to get the solid product and successively wash with ethanol After repeated washing with cyclohexane, the rare earth Dy can be obtained by drying 3+ Doped indium tungstate nanomaterials.

Embodiment 3

[0022] will InCl 3 (1.76 mmol), Na 2 WO 4 2H 2 O (3.0 mmol) and Dy (NO 3 ) 3 ·5H 2 O (0.24 mmol) was dissolved in a mixed solvent of n-hexane (2.0 mL) and N,N-dimethylacetamide (4.0 mL), added tetrabutylammonium bromide (TBAB, 1.0 mmol), and transferred to 20 mL reaction kettle, stir evenly initially, then add 40 μL n-propylamine dropwise, continue to stir evenly, adjust the pH to about 8.5, then react at a constant temperature of 170°C for 20 hours, naturally cool to room temperature, centrifuge to get the solid product and successively wash with ethanol After repeated washing with cyclohexane, the rare earth Dy can be obtained by drying 3+ Doped indium tungstate nanomaterials.

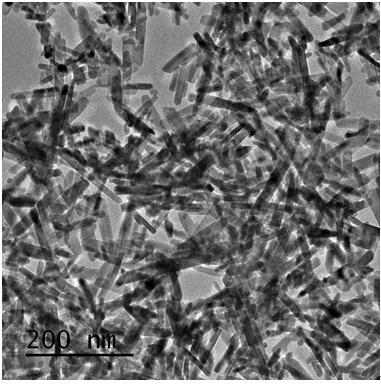

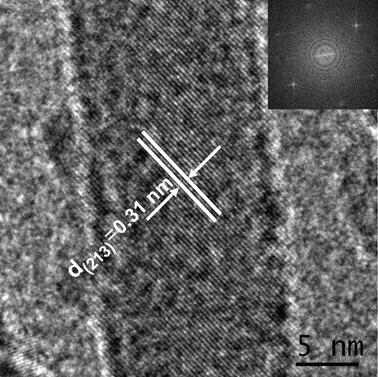

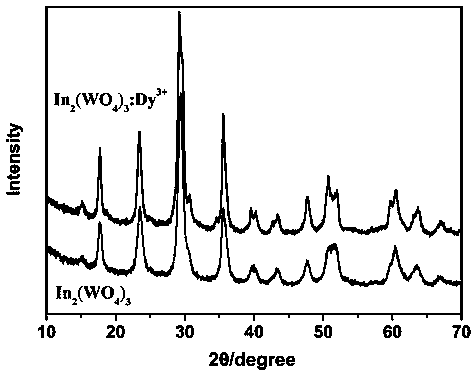

[0023] Get the rare earth Dy prepared by embodiment 1 3+ The doped indium tungstate nanomaterials were tested by XRD (Rigaku UltimaIII diffractometer, CuKa (λ= 1.5418Å), operating voltage 40 kV and 40 mA) and transmission electron microscope characterization (FEI TECNAIG2), while the emission s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com