Preparation method of TiO2 microspheres with special hollow structure

A technology of hollow structure and microspheres, applied in the direction of nanotechnology, titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of damage, high cost, environmental pollution microsphere structure, etc., and achieve simple process, high yield, and reliable strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

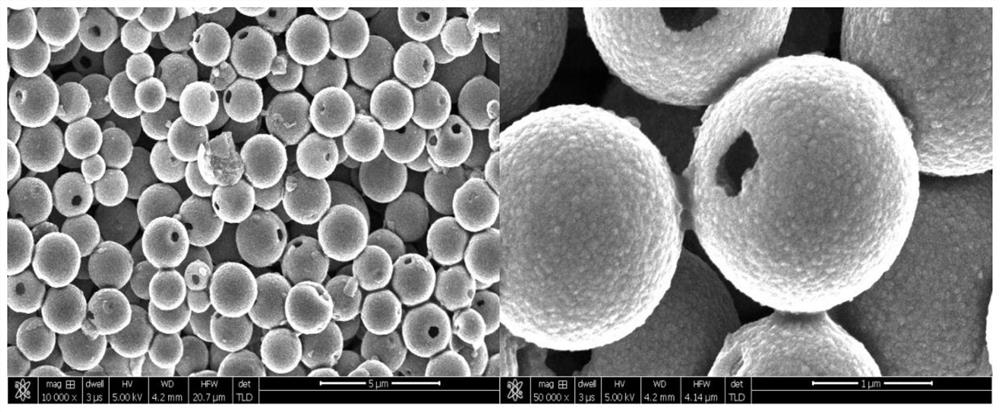

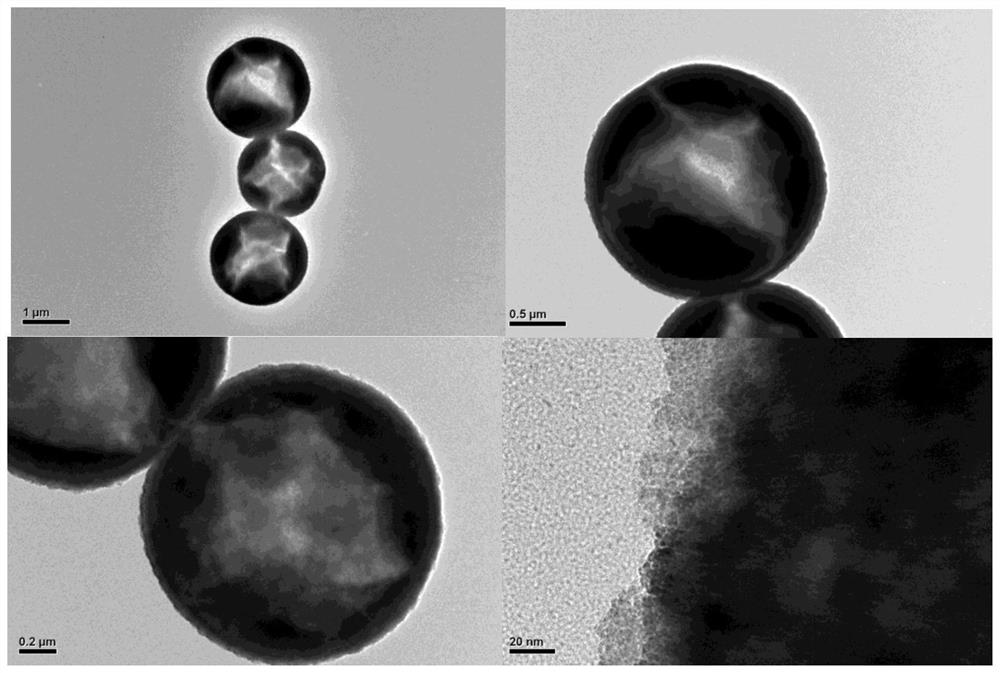

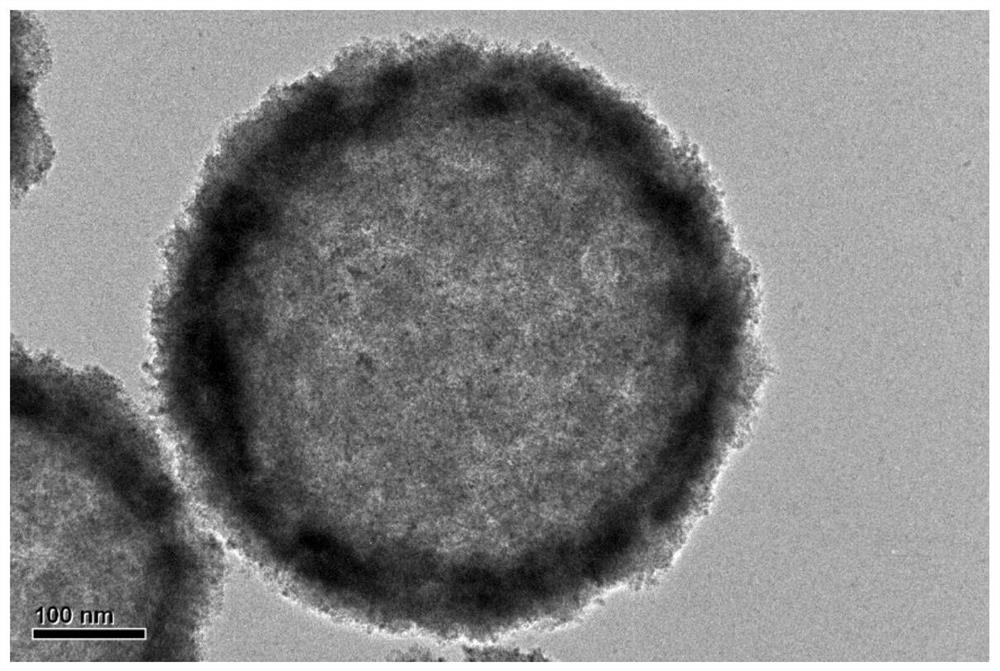

[0019] After mixing 10mL of acetylacetone and 40mL of diethyl ether, add 2mL of tetra-n-butyl titanate, stir evenly, add it to the reaction kettle, react with solvent heat at 200°C for 12h, cool naturally, centrifuge, wash and dry to obtain special TiO with hollow structure 2 Microspheres, 1-3 μm in diameter.

Embodiment 2

[0021] After mixing 15mL of acetylacetone and 35mL of diethyl ether, add 2mL of tetra-n-butyl titanate, stir evenly, add it to the reaction kettle, and conduct a solvothermal reaction at 180°C for 15h. After natural cooling, centrifuge, wash and dry to obtain special TiO with hollow structure 2 Microspheres, 1-3 μm in diameter.

Embodiment 3

[0023] After mixing 20mL of acetylacetone and 30mL of diethyl ether, add 2mL of tetra-n-butyl titanate, stir evenly, add it into the reaction kettle, and conduct a solvothermal reaction at 220°C for 10 hours. After natural cooling, centrifuge, wash and dry to obtain special TiO with hollow structure 2 Microspheres, 1-3 μm in diameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com