Pipe coke oven

A tubular and coking technology, used in coke ovens, petroleum industry, etc., can solve the problems of difficulty in coking out coke and high crushing rate of coke, so as to reduce the cost of coking, optimize the coking process, and achieve the effect of cleaner production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

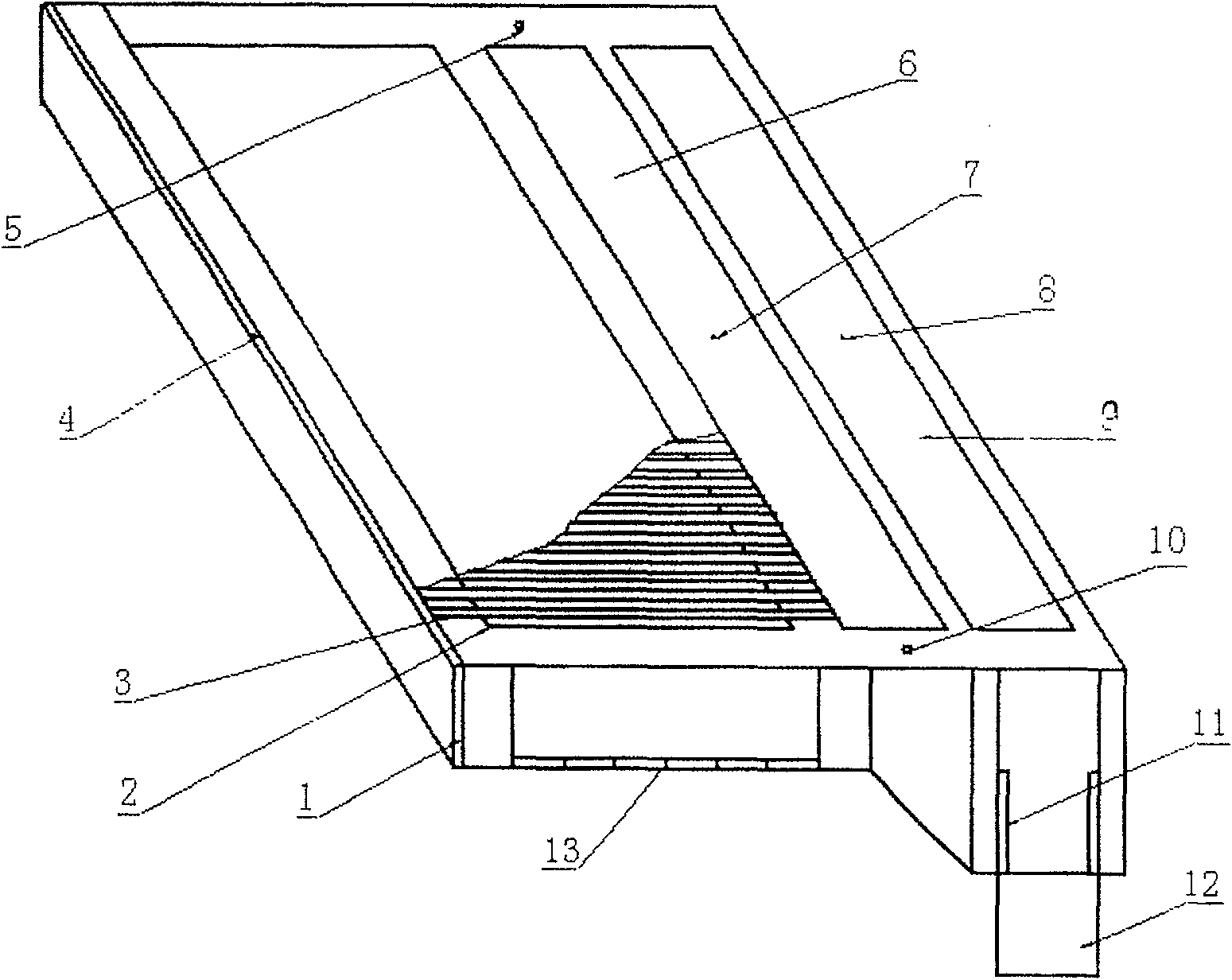

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail

[0018] figure 1 Among them, the gas collection chamber (1) is located at the charging end of the coking furnace and communicates with the tubular carbonization chamber (3), and the top of which is provided with a gas collection pipe (4) for collecting the charging of the coking furnace and during the carbonization process. A small amount of overflowing gas is sent to the combustion chamber (2) as fuel, and the gas collection chamber (1) has a hole corresponding to the size of the tubular carbonization chamber (3), and is equipped with a movable valve. The charging device is loaded into the tubular carbonization chamber (3) through the gas collection chamber (1), and at the same time pushes the carbonized coke into the coke discharge chamber (6).

[0019] The tubular carbonization chamber (3) consists of a plurality of pipes arranged from top to bottom to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com