High-toughness manganese-containing aluminum alloy

A manganese-aluminum alloy and high-strength technology, which is applied in the field of high-strength and tough aluminum alloys, can solve the problems of increasing hot cracking tendency macro-segregation, reducing the plastic toughness of aluminum alloys, and deteriorating the comprehensive properties of materials, so as to promote uniform plastic deformation, increase strength, The effect of ensuring uniform plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

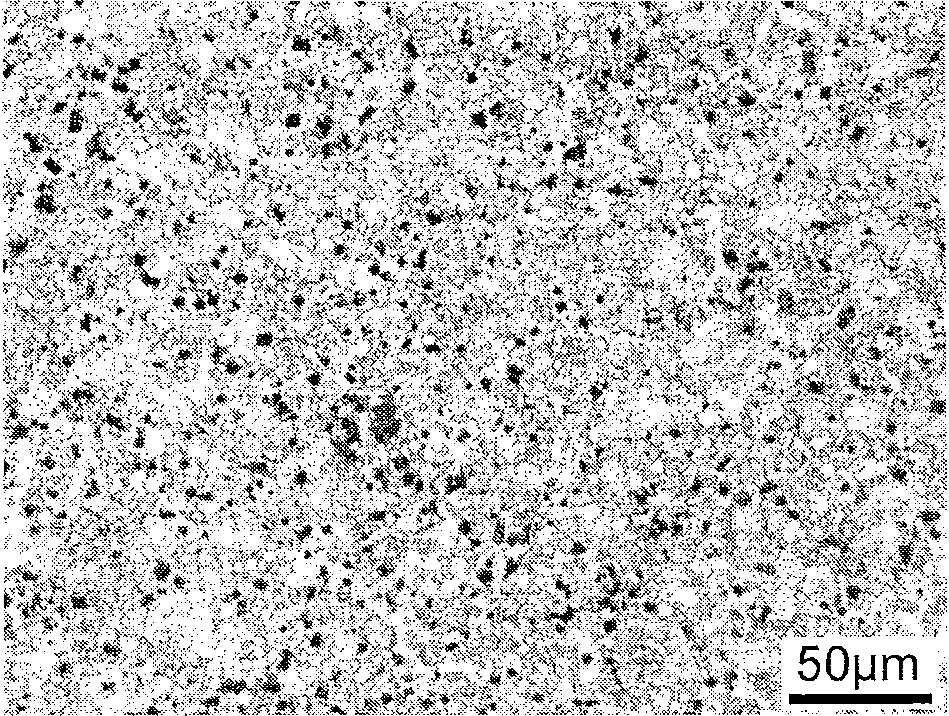

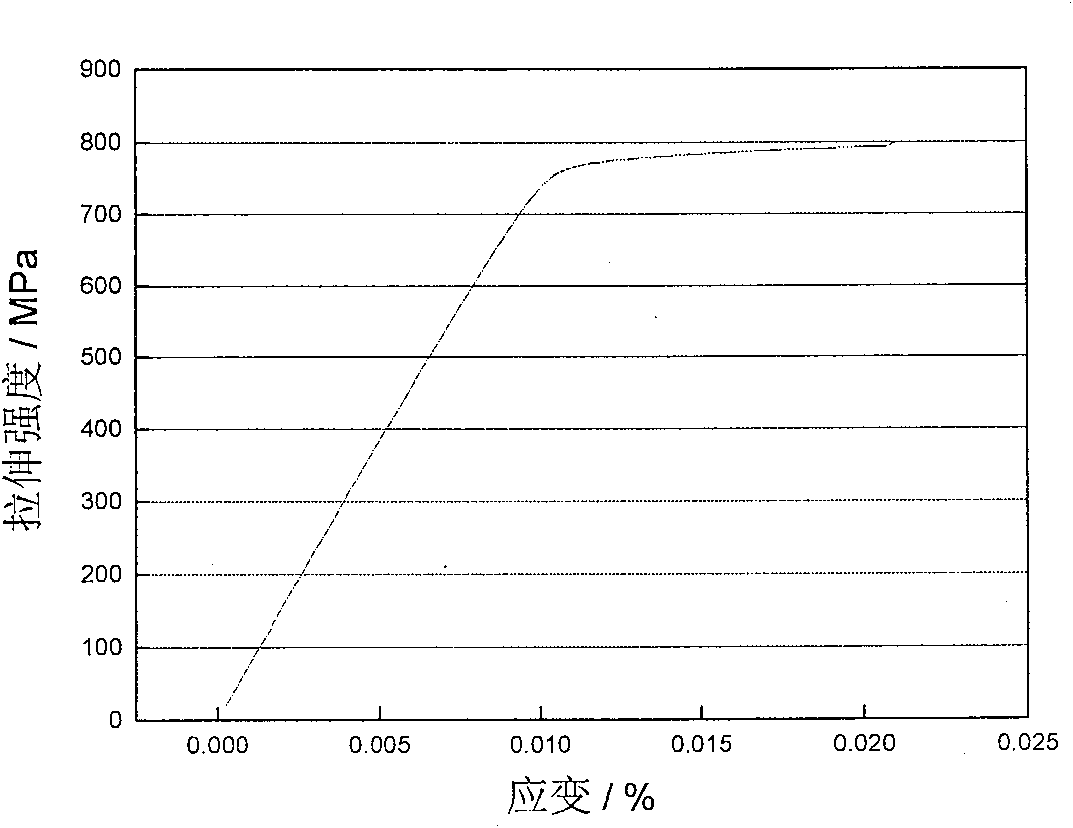

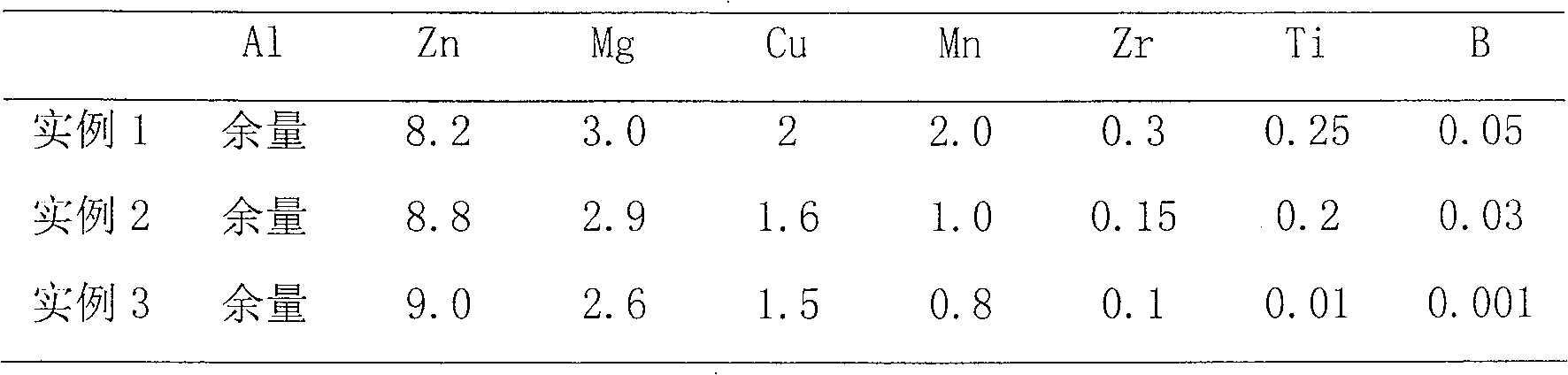

[0013] The composition used in the aluminum alloy example is shown in Table 1:

[0014] Table 1 example composition list (unit: wt %)

[0015]

[0016] Adopt the following preparation process:

[0017] 1. Preparation of manganese-containing high-strength and tough aluminum alloy deposition blanks by spray forming.

[0018] According to the composition of the prepared high-strength and tough aluminum alloy, put the commercially available aluminum-based master alloy into the induction melting furnace, and then vacuumize it. After reaching a certain vacuum degree, wash the furnace twice with high-purity nitrogen gas and then melt the aluminum alloy. After all the aluminum alloys are melted, they are spray-formed to produce deposited blanks of manganese-containing high-strength and tough aluminum alloys. The specific process parameters are as follows: melt temperature 850 ° C, atomization pressure 0.5 MPa, diversion nozzle diameter 3 mm, receiving distance 450 mm, The eccent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com