Substitution material in use for testing construction machinery for asphalt pavement, and its prodn. tech

A technology of asphalt pavement and construction machinery, which is applied in the field of substitute materials, can solve the problems of flying mineral powder, increasing the actual workload of the test, and the fluidity of dry material cannot fully and truly reflect the fluidity of hot asphalt mixture. Economic and social benefits, shortening product replacement cycle, and reducing road maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

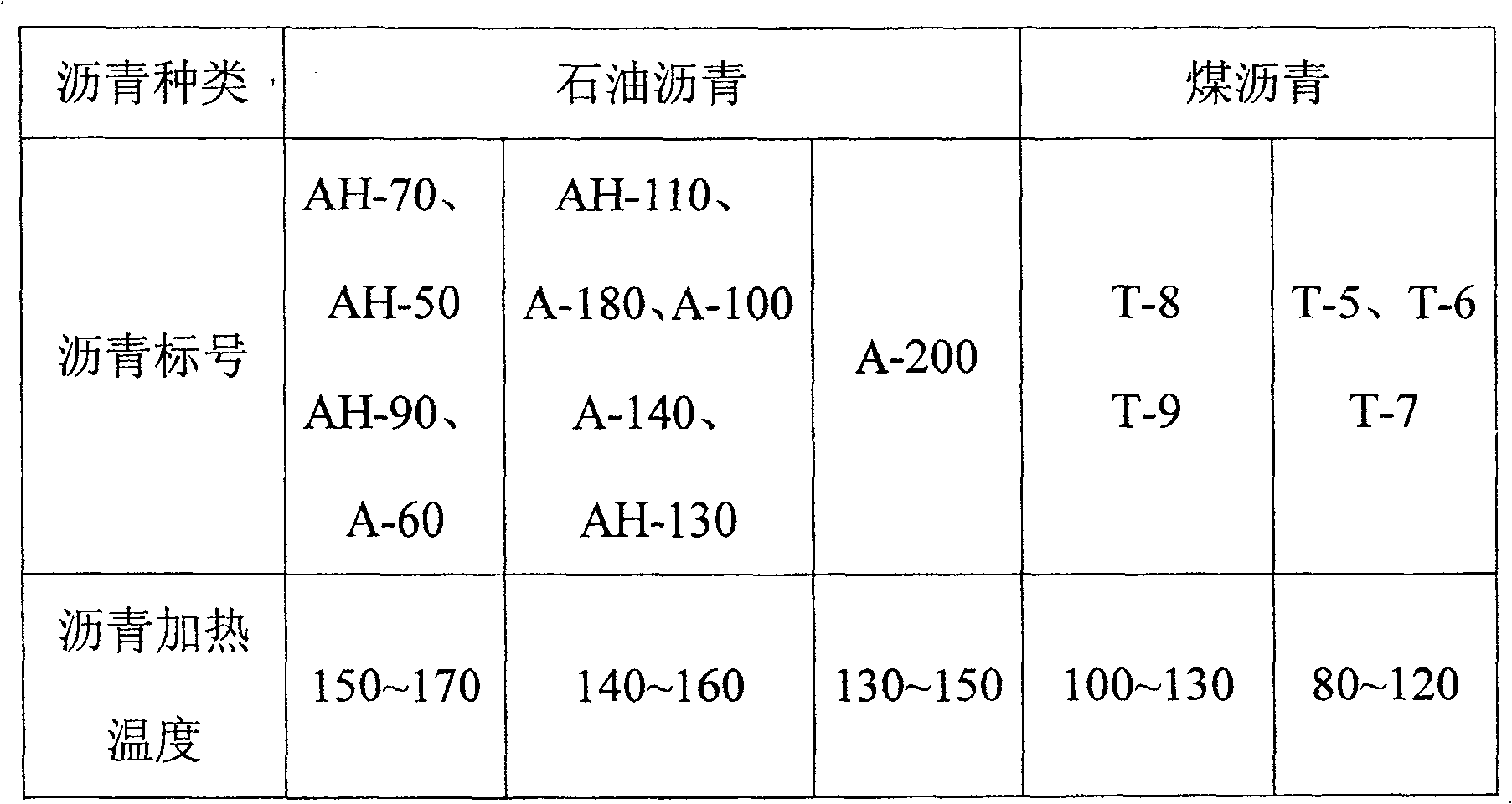

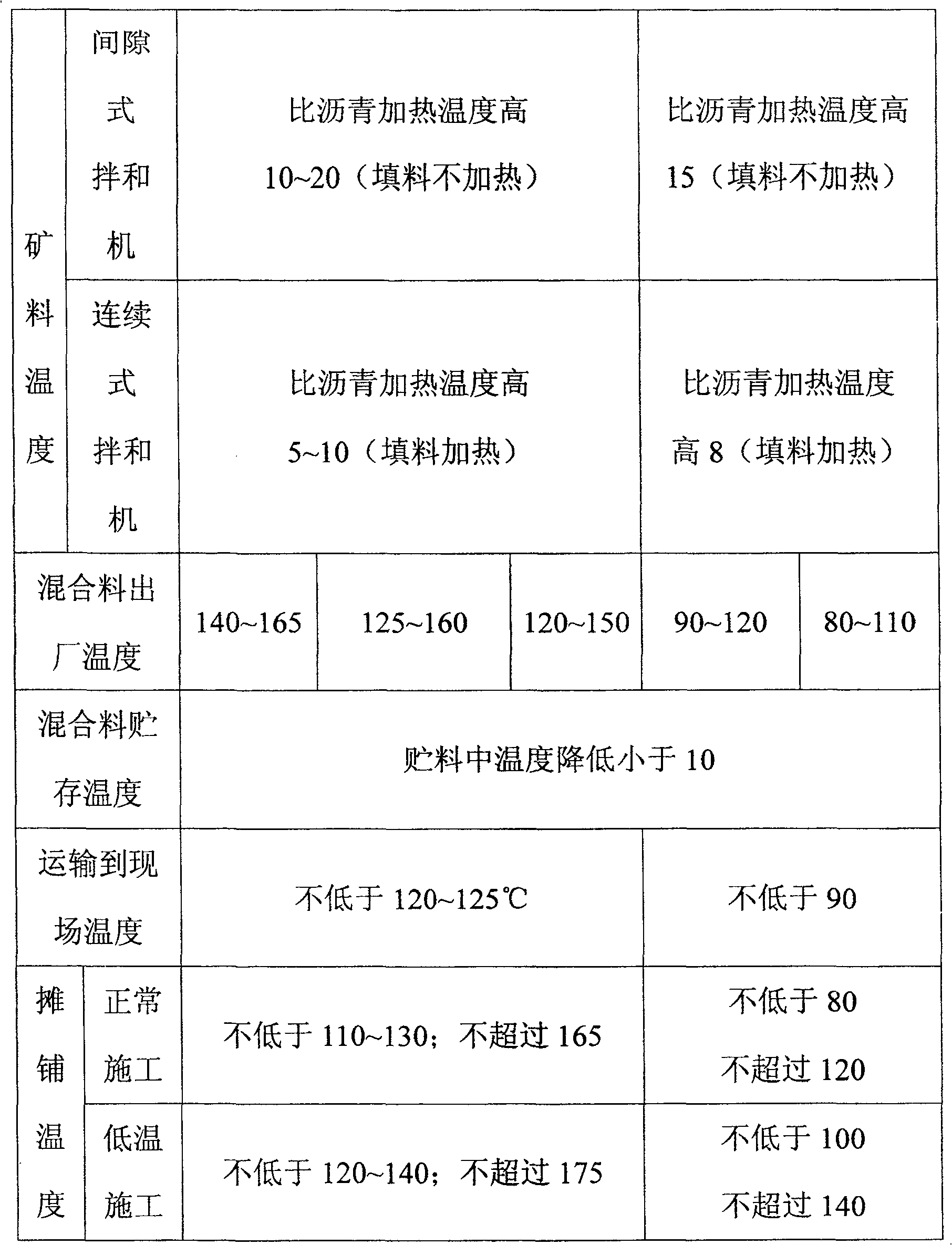

[0036] Example 1: Preparation of 135°C asphalt mixture (asphalt grade is Donghai brand AH-70, ore grading is AC-20I) test substitute material at room temperature (25°C).

[0037] The viscosity value of Donghai brand AH-70 bitumen at 135°C is 0.44Pa·s obtained from relevant standards. Therefore, 0.44Pa·s is taken as the target viscosity value.

[0038] Through the quasi-slump experiment on hot asphalt mixture at 135℃, the target slump value is 189mm.

[0039] According to the target viscosity value of 0.44Pa s, select a lubricating oil with the closest viscosity at 25°C, that is, select a medium-duty industrial valve with the code name N220 (that is, the ISO viscosity grade is 220) from GB 5903-1995. Type gear oil (ie L-CKC220). Actually, the lubricating oil selected may be any lubricating oil with a viscosity slightly less than 0.44 Pa·s.

[0040] Stir lubricating oil L-CKC220 and mineral material graded as AC-20I according to the oil-stone ratio of 3% to form a lubricating...

Embodiment 2

[0043] Embodiment 2: quasi-slump test.

[0044] 1. Purpose and scope of use:

[0045] 1) Measure the slump of the mixture to evaluate the workability of the mixture. If necessary, it can also be used to evaluate the change of workability of the mixture with the resting time of the mixture.

[0046] 2) It is suitable for plastic and fluid mixtures with the maximum particle size of the aggregate not exceeding 40mm and the slump of 10mm to 230mm.

[0047] 2. Instruments and equipment:

[0048] 1) Slump cylinder: made of iron sheet with a thickness of 2mm to 3mm, and the inner wall of the cylinder must be smooth;

[0049] 2) Two 300mm steel rulers, 40mm aperture sieve, charging funnel, trowel, small shovel, thermometer, etc.

[0050] 3. Experimental steps:

[0051] 1) Mix the mixture evenly. If the particle size of the aggregate exceeds 40mm, it should be removed by wet sieving, or it can be removed manually.

[0052] 2) Rinse the slump cylinder and keep it moist, put it on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com