Silicon solar cell with hot spot laser etching ring and preparing method thereof

A technology of silicon solar cells and solar cells, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of rising cost of solar cells, failure of leakage current to meet standards, and no treatment methods, etc., to achieve low cost and reduced surface leakage current Small size, the effect of reducing battery production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, the preparation method of the crystalline silicon solar cell with hot spot laser engraving ring, its process steps are as follows:

[0019] 1. Find out the position and size of the hot spot on the silicon wafer surface of the crystalline silicon solar cell with the hot spot and mark around the hot spot;

[0020] 2. Freeze the battery silicon wafer;

[0021] 3. Use a laser beam to etch a circle around the hot spot to isolate the hot spot from the metal electrode junctions of other parts of the battery.

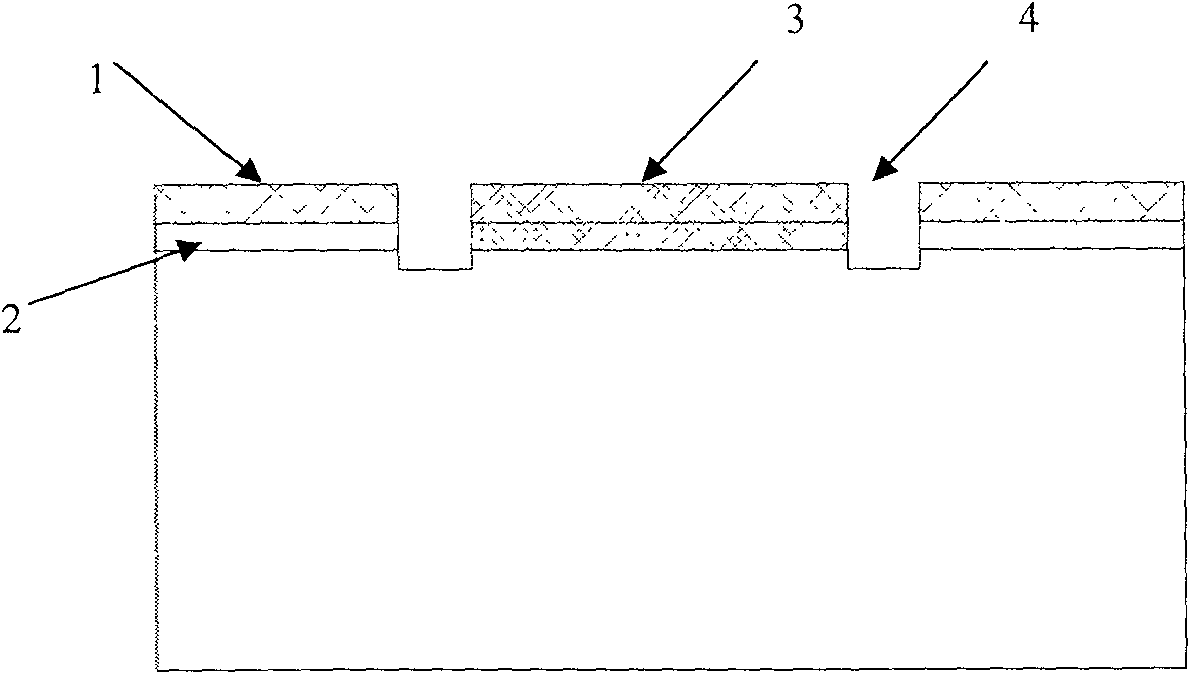

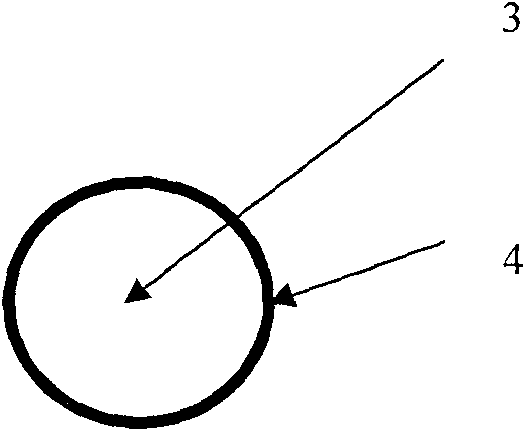

[0022] The silicon solar cell produced according to the above method has a metal electrode layer 1 and a Pn junction layer 2 on the surface, and a laser etching ring 4 is provided around the hot spot 3 on the surface, and the laser etching ring connects the hot spot and the metal of other parts of the battery. The electrode junctions are isolated. Since the laser etching ring separates the hot spot from the metal electrode, and the resistance of the Pn ju...

Embodiment 2

[0023] Embodiment 2 is basically the same as Embodiment 1, except that the battery to be processed is a thin-film solar cell, and step 2 is to apply water around the hot spot as a coolant. The depth of the laser etched ring penetrates the Pn junction, isolating the hot spot from the Pn junction in the rest of the cell.

Embodiment 3

[0024] Embodiment 3 is basically the same as Embodiment 1, except that step 2 is to apply alcohol around the hot spot as a cooling agent.

[0025] Such as figure 1 with figure 2 As shown, the silicon solar cell produced according to the above method has a metal electrode layer 1 and a Pn junction layer 2 on the surface, and a laser etching ring 4 is provided around the hot spot 3 on the surface, and the depth of the laser etching ring penetrates the Pn junction, Isolate the hot spot from the Pn junction, so the hot spot does not generate cell surface leakage current or produces minimal cell surface leakage current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com