Blind screw hole cleaning machine

An internal thread and washing machine technology, applied in mechanical equipment, engine components, cleaning methods and utensils, etc., can solve the problems of unreliability, low efficiency, poor effect, etc., and achieve small footprint, high production efficiency, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

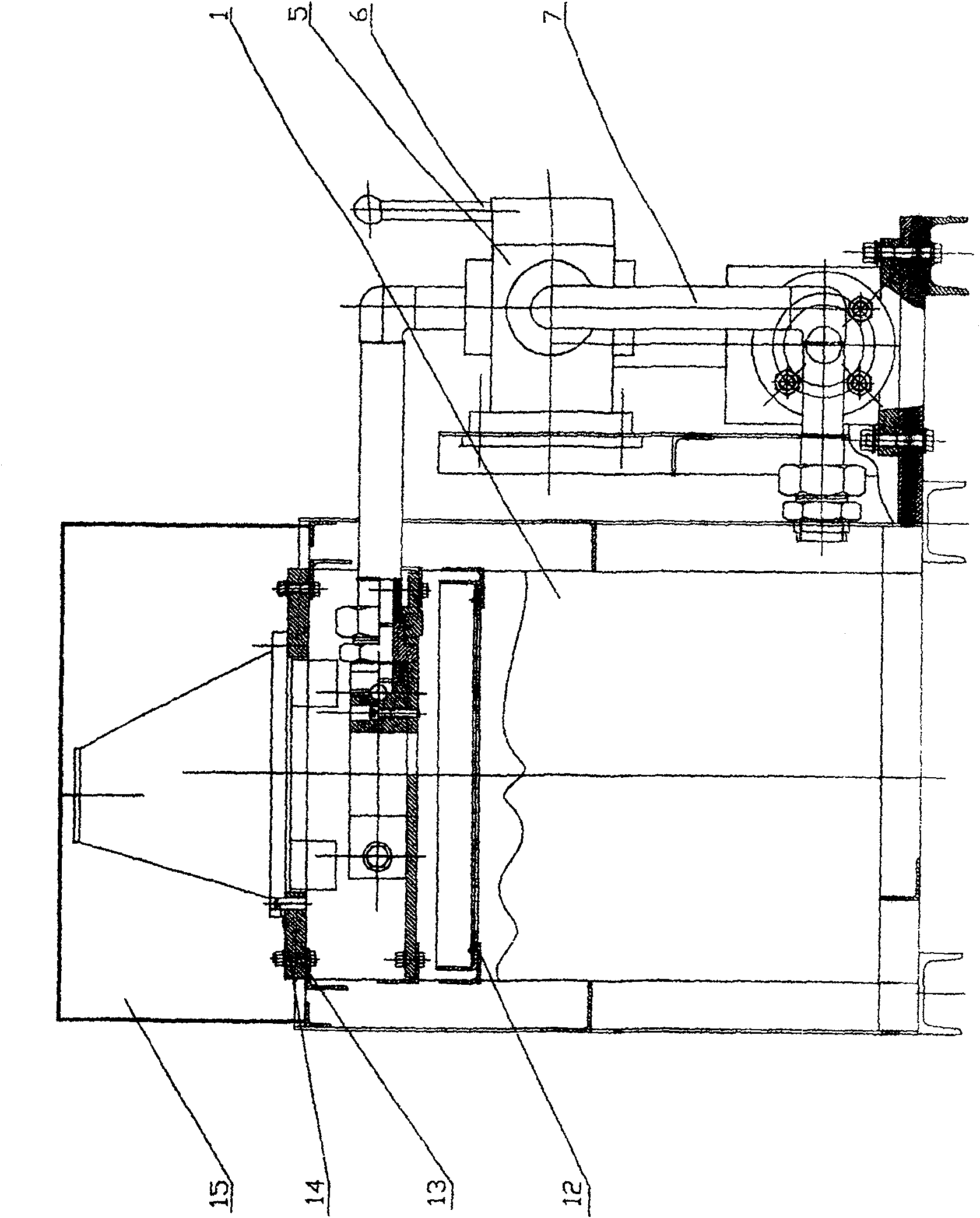

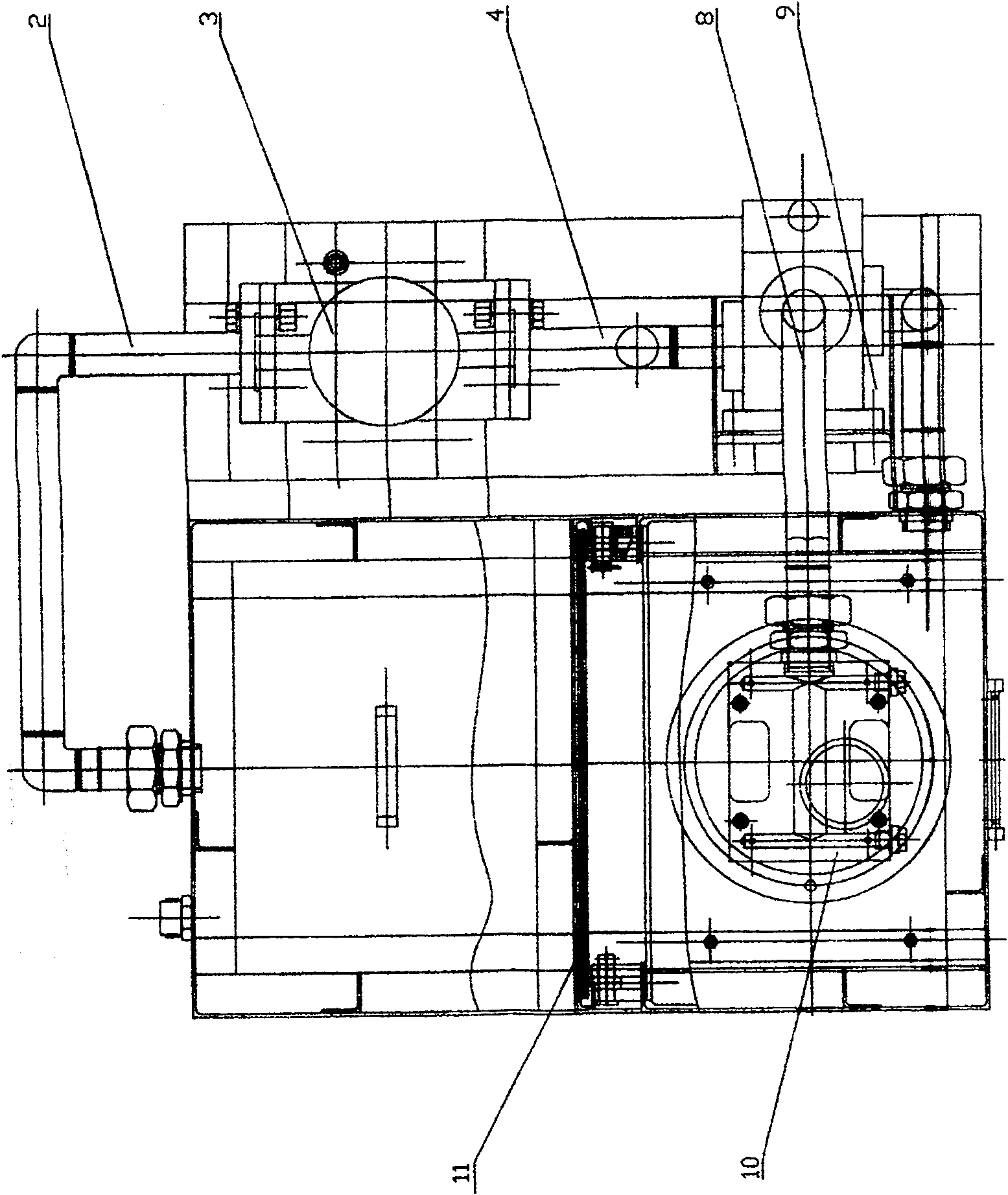

[0017] Example 1: Taking the 3CE main reducer housing of the rear axle of the Transit as an example, the bearing cover of the main reducer housing has a 4-M14 threaded hole with a depth of 35°, and the threaded hole is a blind hole.

[0018] The internal thread blind hole cleaning machine includes a frame, a water tank 1, a centrifugal pump 3, a connecting water pipe 4, an electrical control switch 9 and a water spray system 10, the water tank 1 is connected to the water inlet of the centrifugal pump 3 through the water inlet pipe 2, and the centrifugal pump The water outlet of 3 is connected with the water inlet of the two-position three-way assembly 5 through the connecting water pipe 4, and the water outlet of the two-position three-way assembly 5 is connected with the water spray system 10 through the water spray inlet pipe 8. The water return port of the three-way assembly 5 is connected to the water tank through the return pipe 7, and the built-in valve port of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com