Rigidity-variable full-automatic power vibration-absorber

A technology of dynamic vibration absorber and variable stiffness, which is applied to devices for vibration reduction and noise control of electrical equipment, and in the field of machinery. It can solve the problem of insufficient vibration absorption effect of semi-active control vibration absorbers, high control energy, and narrow control bandwidth of passive control vibration absorbers. and other problems, to achieve the effect of easy control method, low energy consumption and small additional mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

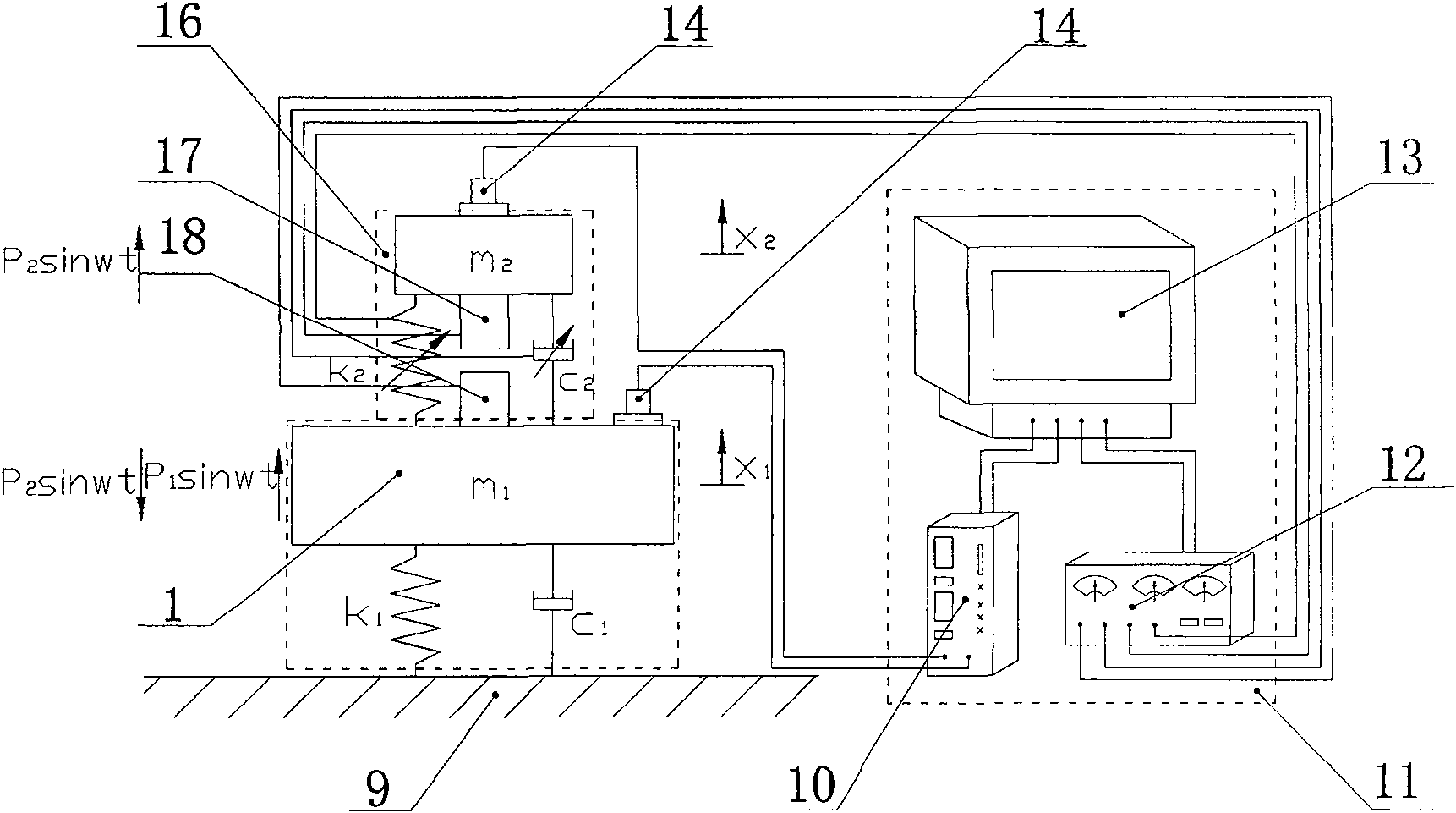

[0033] The fully active dynamic shock absorber with variable stiffness includes an execution part 16, a control part 11 and a sensor 14, and the shock absorber control part 11 includes a charge amplifier 10, a power amplifier 12 and a data acquisition and processing system 13, see figure 1 .

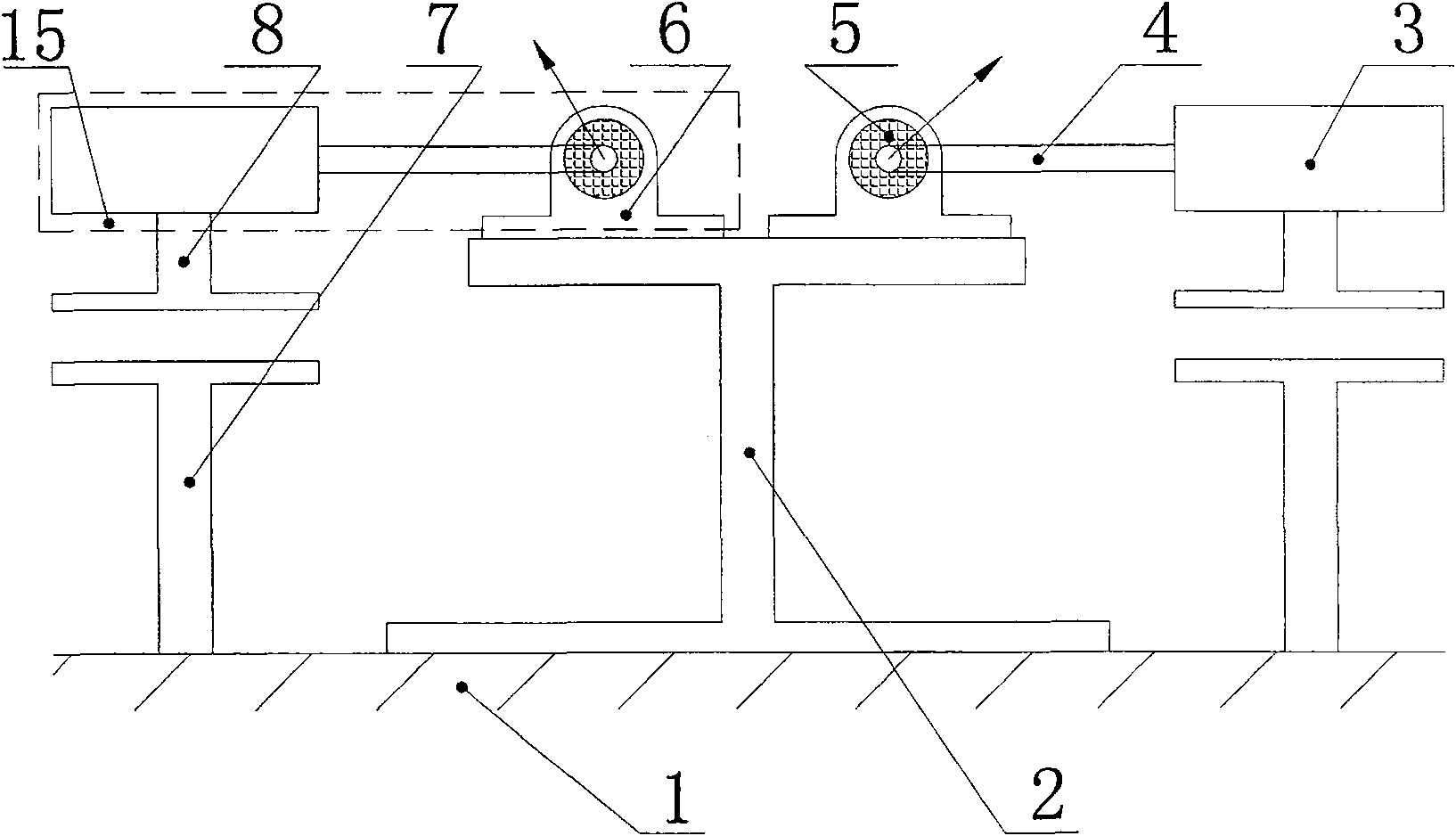

[0034] Such as figure 2 , Figure 4The executive components of the electric field force-driven rotary fully active dynamic vibration absorber with variable stiffness are composed of a vibration damping object 1; a base frame 2; a moving mass block 3; an annular guide rod 4; a magnetorheological elastomer 5; ; Capacitor pole plate 8 connected to the moving mass for providing active force; Capacitor pole plate 7 connected to the vibration reduction object for providing active force; Exciting coil 21; Bearing 24; Outer ring magnetic ring 25; device 26. The lower end of the base frame 2 is fixed on the damping object 1 with threads, and the upper end of the base frame 2 is connected with...

Embodiment 2

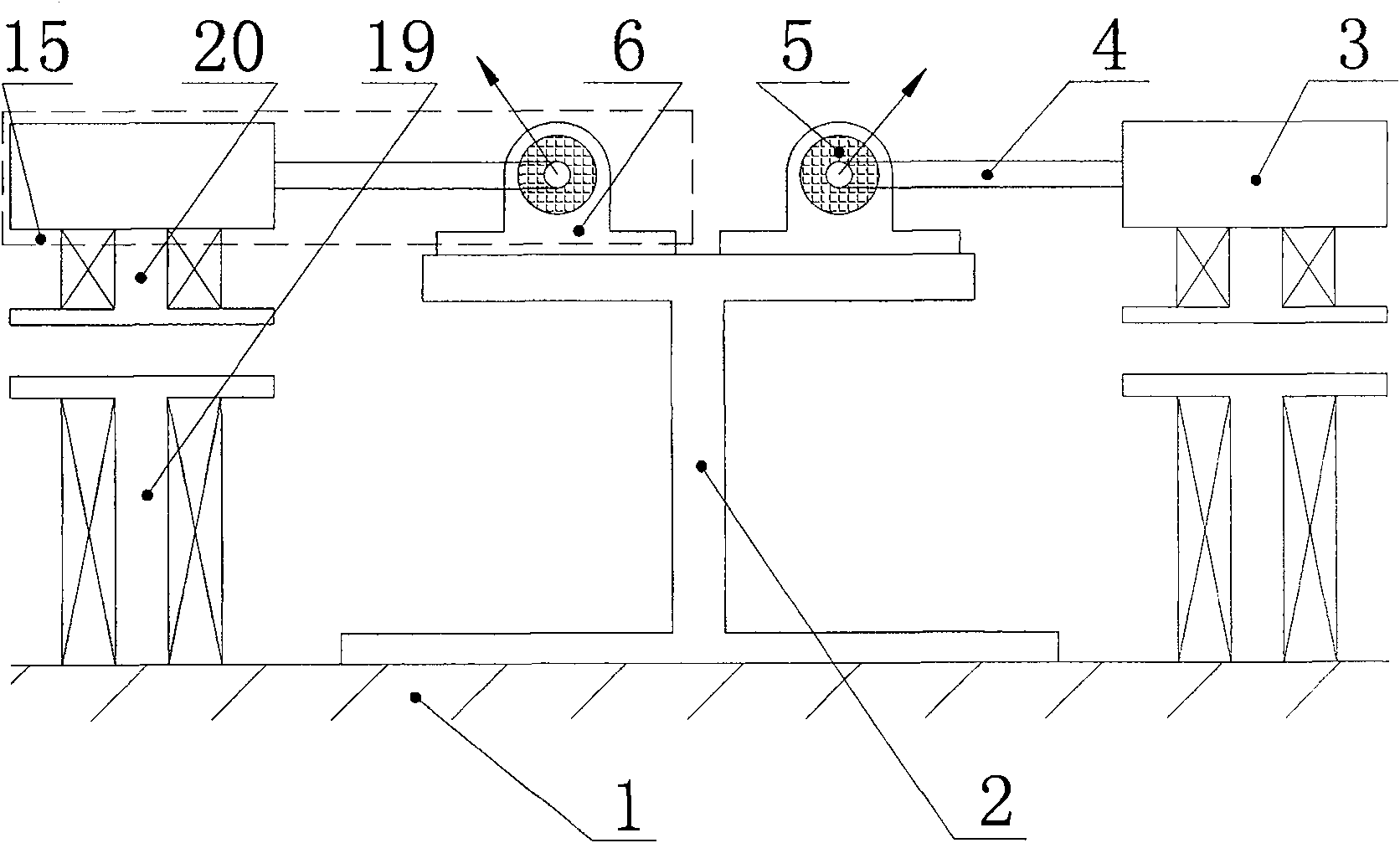

[0039] Such as image 3 , Figure 4 The executive components of the magnetic field force-driven rotary fully active variable stiffness dynamic shock absorber are composed of a vibration damping object 1; a base frame 2; a moving mass block 3; an annular guide rod 4; a magnetorheological elastomer 5; ; The energized coil 20 that is connected to the moving mass block for providing active force; The energized coil 19 that is connected with the vibration reduction object for providing active force; Exciting coil 21; Bearing 24; Outer ring magnetic ring 25; 26 composed. The lower end of the base frame 2 is fixed on the damping object 1 with threads, and the upper end of the base frame 2 is connected with the base 6 with bolts, and the ring guide rod 4 is connected with the base 6 through the bearing 24 so that the ring guide rod 4 can only Rotate around the axis, the outer ring magnetic ring 25 is fixed together with the base 6 through threaded connection, the magnetorheological ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com