Silica gel- water adsorption refrigerating device without vacuum switch valve

A vacuum-free, water adsorption technology, applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems of reduced average cooling capacity, reduced reliability, cooling capacity loss, etc., and achieves improved operational reliability, structural Simple and reliable, the effect of automatic system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

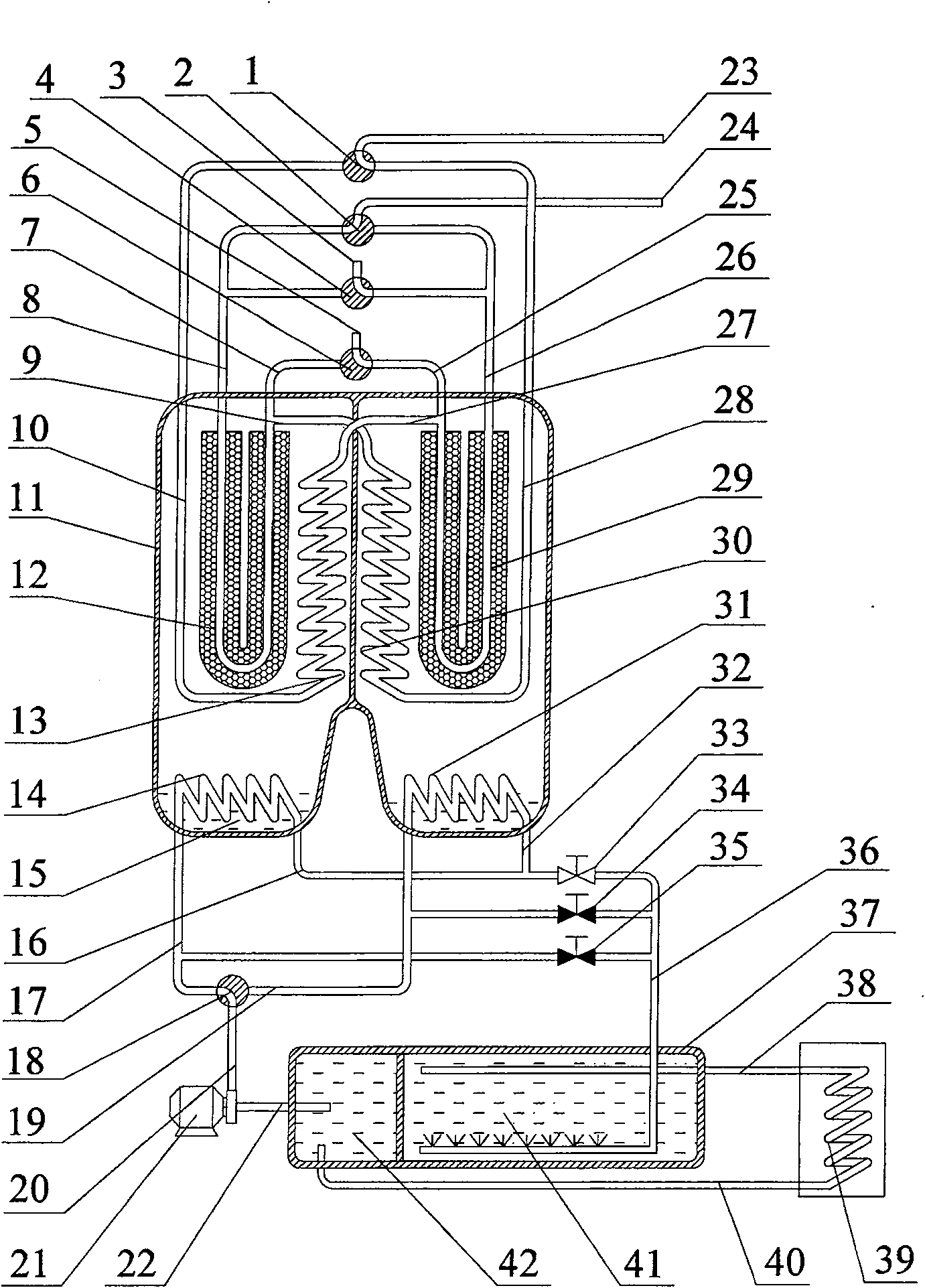

[0014] Such as figure 1 As shown, this embodiment includes: cooling water inlet three-way valve 1, cooling water outlet three-way valve 2, hot water outlet connecting pipe 3, hot water outlet three-way valve 4, hot water inlet connecting pipe 5, hot water inlet three-way valve 6. Left adsorption bed inlet connection 7, left adsorption bed outlet connection 8, right condenser outlet connection 9, left condenser inlet connection 10, shell 11, left adsorption bed 12, left condenser 13, left evaporator 14, refrigerant 15. Left evaporator outlet connection 16, left evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com