Method for preparing poultry cholera microcapsule vaccine

A technology for microcapsules and fowl cholera, which is applied in the field of bioengineering and achieves the effects of convenient use, long storage period and scientific method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

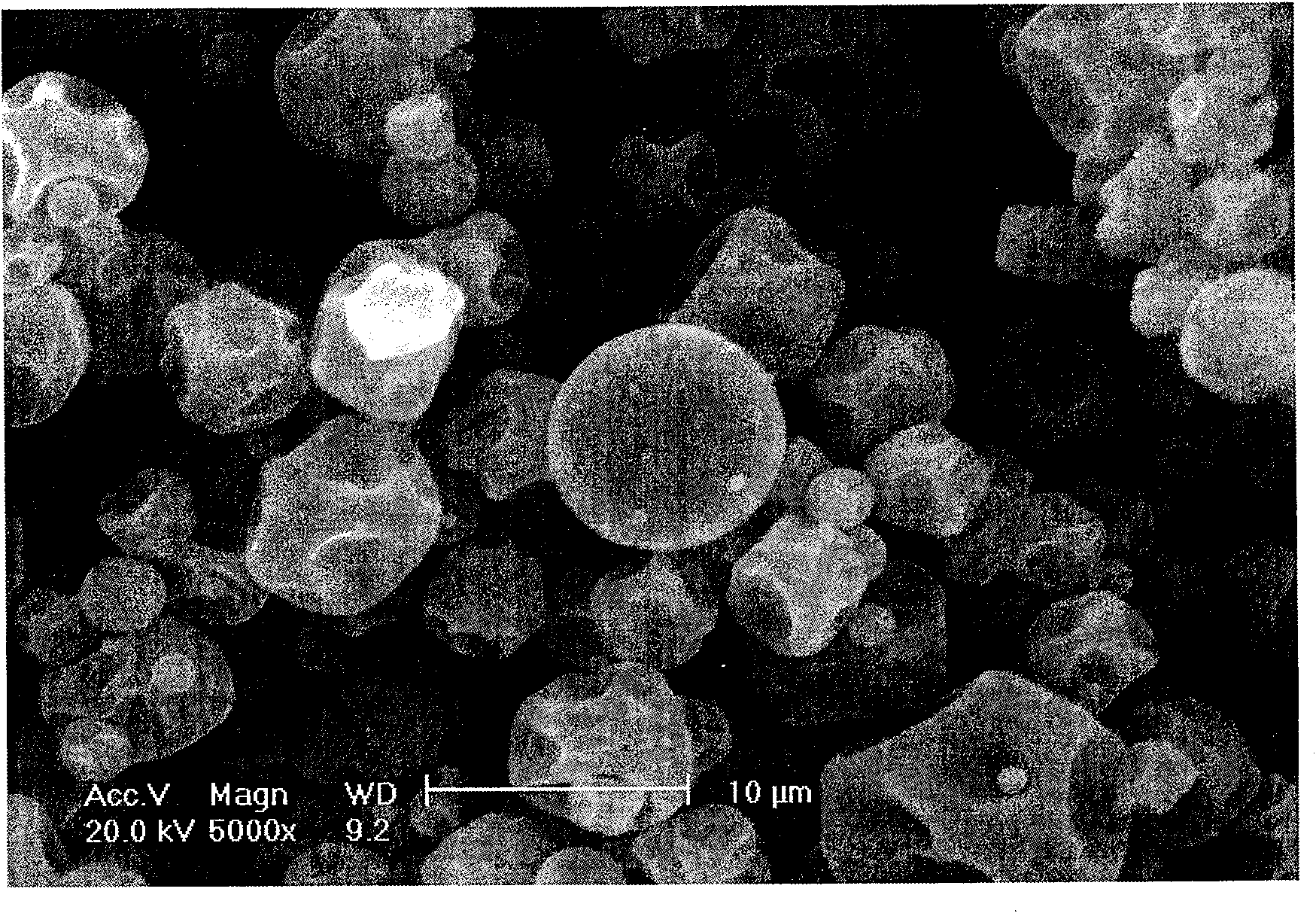

[0015] After rejuvenating the freeze-dried strains of Pasteurella multocida type A, select typical colonies and culture them to make seed liquid, use the flat bottle solid culture method to obtain semi-finished products with a bacterial count of more than 12 billion / ml, and pass the inactivation test Then mix with sodium alginate solution for primary emulsification, then mix this emulsion with chitosan solution for secondary emulsification, dehydrate the final emulsion through a spray dryer, and make microcapsule vaccine dry powder, each gram of vaccine contains bacteria The body size is 350 billion, and the vaccine particle size ranges from 2-9um (see attached figure 1 ). The test chickens produced an immune response 3 days after being inoculated with the vaccine, and within 6 months of immunization, the average protection rate was 80.67%.

Embodiment 2

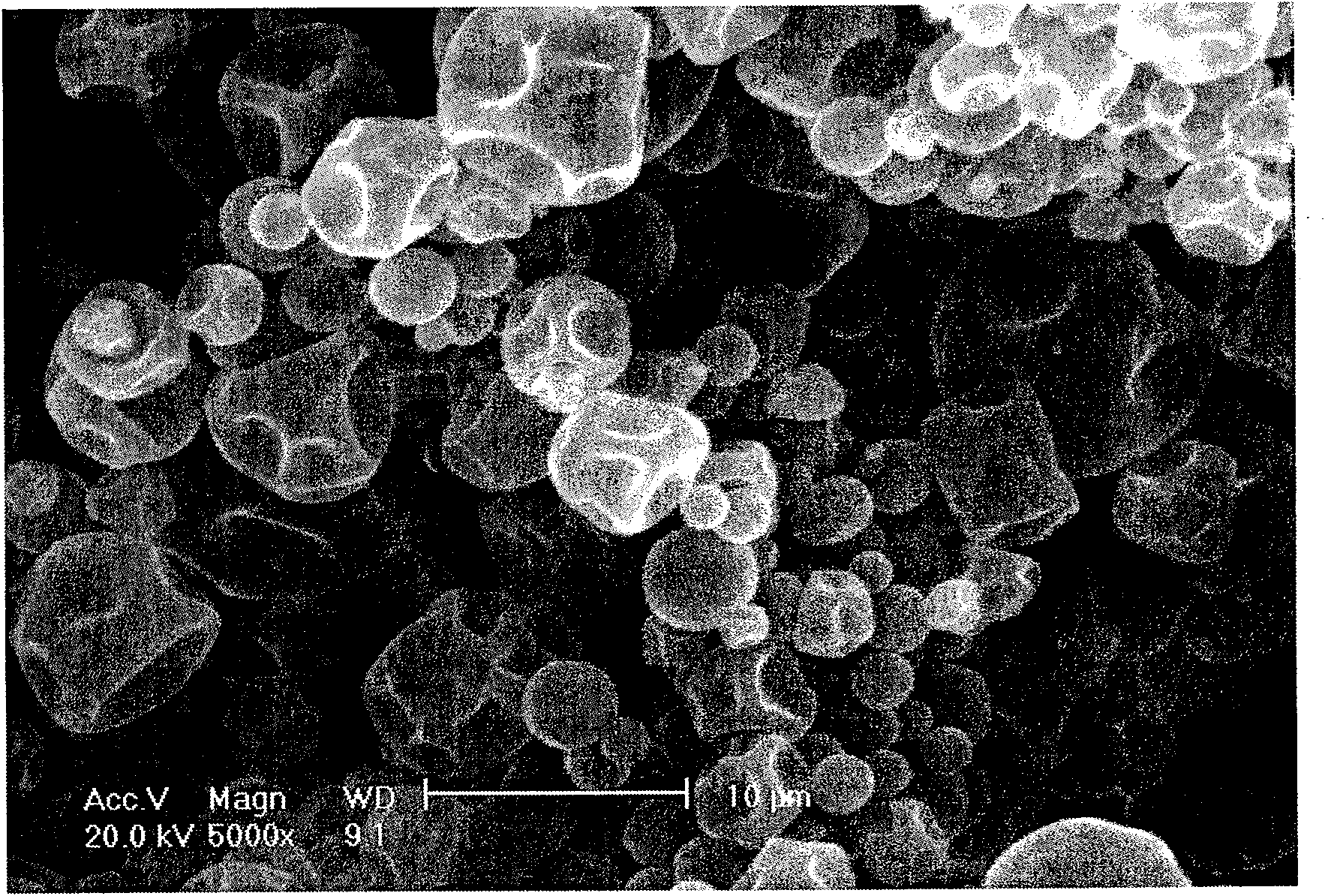

[0017] After the freeze-dried strain of Pasteurella multocida type A is rejuvenated, typical colonies are selected and cultured to make seed bacterial liquid, and the semi-finished product containing more than 9 billion bacteria / ml is obtained by deep aerated fermentation culture method, which is tested by inactivation Then mix with sodium alginate solution for primary emulsification, then mix this emulsion with chitosan solution for secondary emulsification, dehydrate the final emulsion through a spray dryer, and make microcapsule vaccine dry powder, each gram of vaccine contains bacteria The body size is 300 billion, and the vaccine particle size ranges from 1-12um (see attached figure 2 ). The test chickens produced an immune response 3 days after being inoculated with the vaccine, and within 6 months of immunization, the average protection rate was 76.32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com