Toilet cistern

A toilet and water tank technology, applied in the field of toilet sanitary ware, can solve the problems that are not conducive to the installation and opening and closing of the flushing and discharging mechanism, reduce the effective water storage capacity of the water tank, and occupy more limited space in the water tank, and achieve convenient layout and installation, simple structure, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

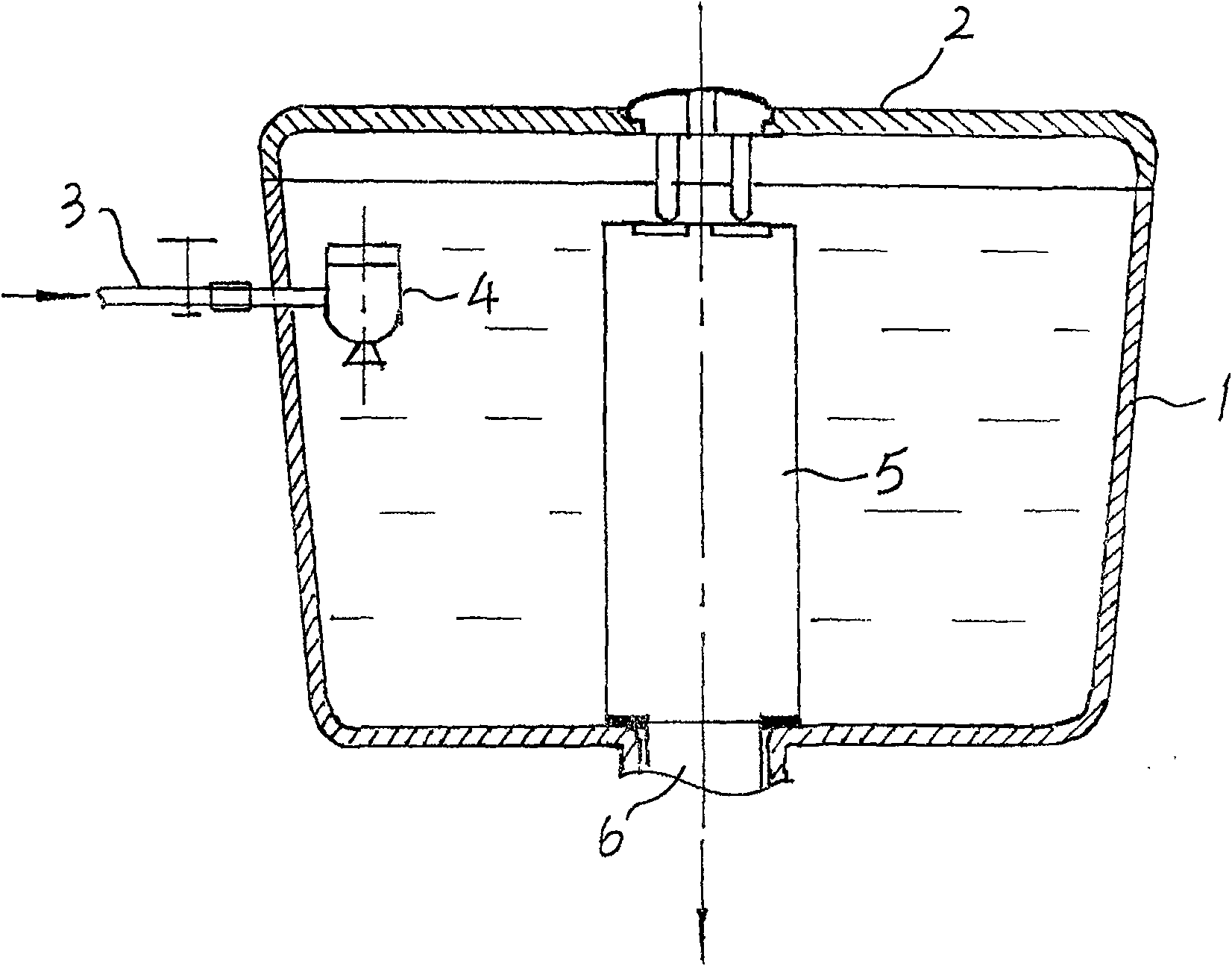

[0011] Embodiment 1 manufactures the standard type toilet water tank of this scheme, structure such as figure 1 Shown:

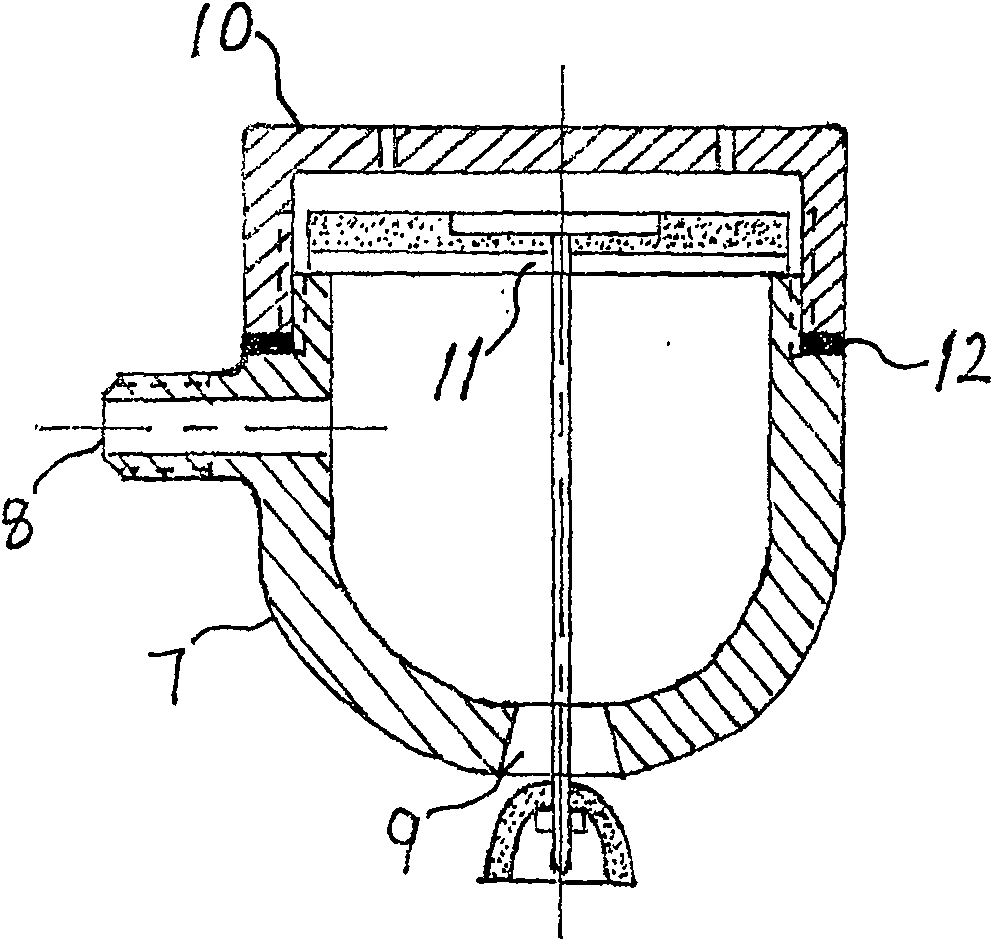

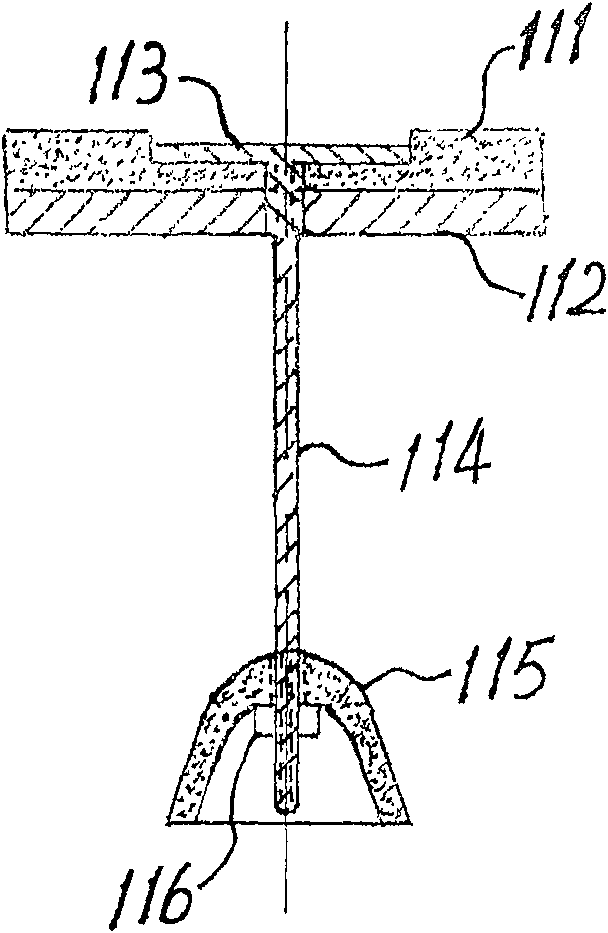

[0012] According to the traditional ceramic toilet manufacturing process, the water tank body 1, which is connected with the toilet body and has a tap water inlet and a flushing water outlet, and a water tank cover 2 with a mounting hole for the flushing and discharging operation button are made; self-made or purchased According to the prior art two grades (3 liters of urine, 6 liters of stool) of the prior art of national standard production flushing and discharging mechanism 5 and supporting parts are stand-by; figure 2 , image 3 The shown structure is made into a miniature pressure differential water level automatic control valve 4; the water inlet 8 of the miniature pressure differential water level automatic control valve body 7 is connected with the municipal tap water pipe network with a tap water pipe joint 3 with a switch, and then suspended and ...

Embodiment 2

[0013] Embodiment 2 Retrofitting the conventional toilet water tank of the prior art into the toilet water tank of the present invention

[0014] In order to popularize and apply the toilet water tank of this program, it is unrealistic and unscientific to scrap the produced toilet equipped with the float lever type water tank, or to require the user to update and replace. And retrofitting is doable and easy. The specific modification method is to keep the existing technology or the part of the flushing and discharging device of the toilet water tank in use unchanged, remove the water level control mechanism of the floating ball, buoy or other structures, and then according to the tap water inlet orientation of various types of water tanks, connect from From the water inlet of the micro-pressure differential water level automatic control valve valve body to the tap water connection pipe 3 of the water tank water inlet, the micro-pressure differential water level automatic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com