Method of preparing multistage silicon nano component

A technology of silicon nanometers and devices, which is applied in the field of preparing multilevel silicon nanometer devices, can solve the problems of limiting the application and development of multilevel devices, complex preparation steps, and slow processing speed, and achieve low cost, broad application prospects, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

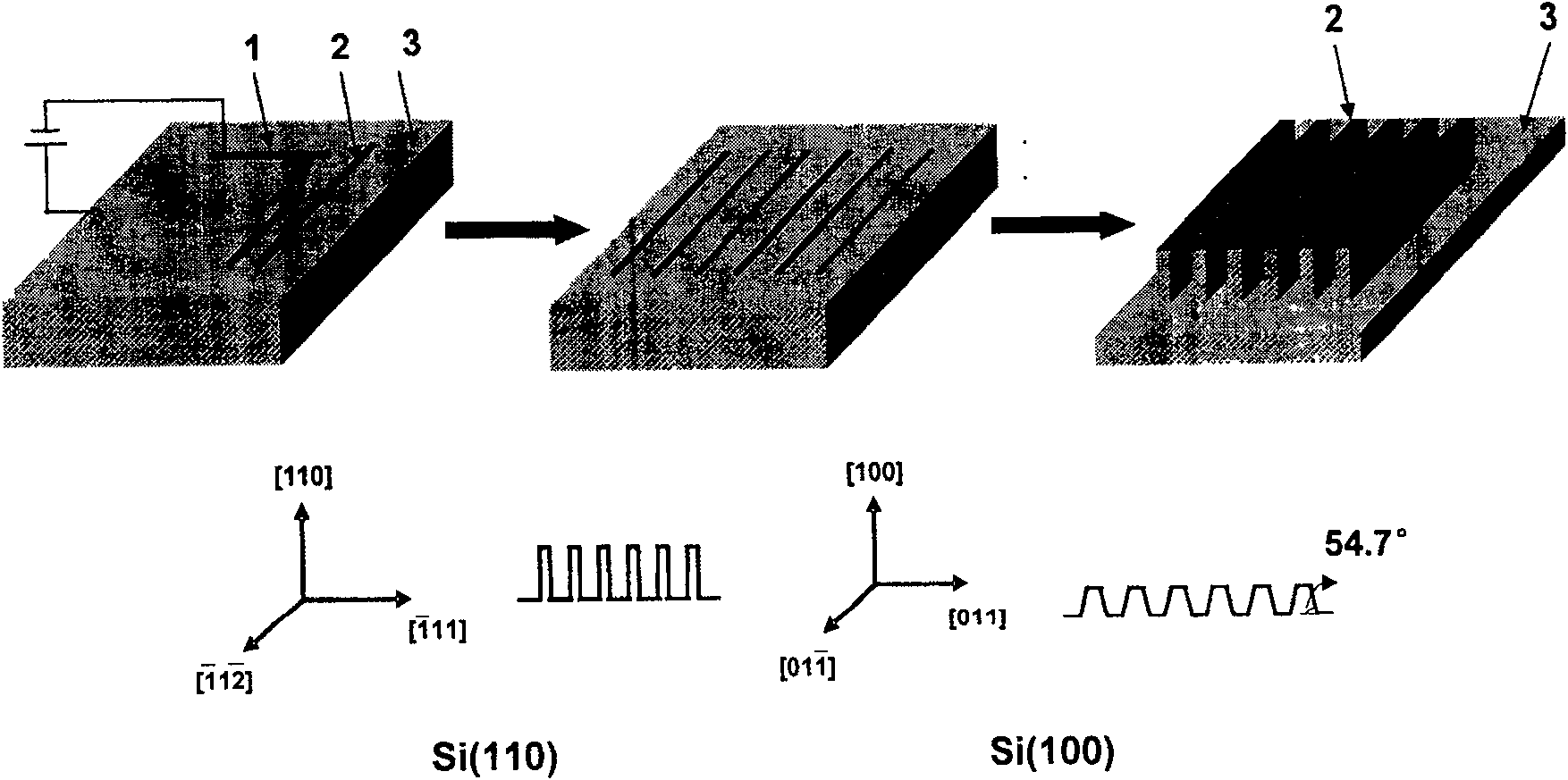

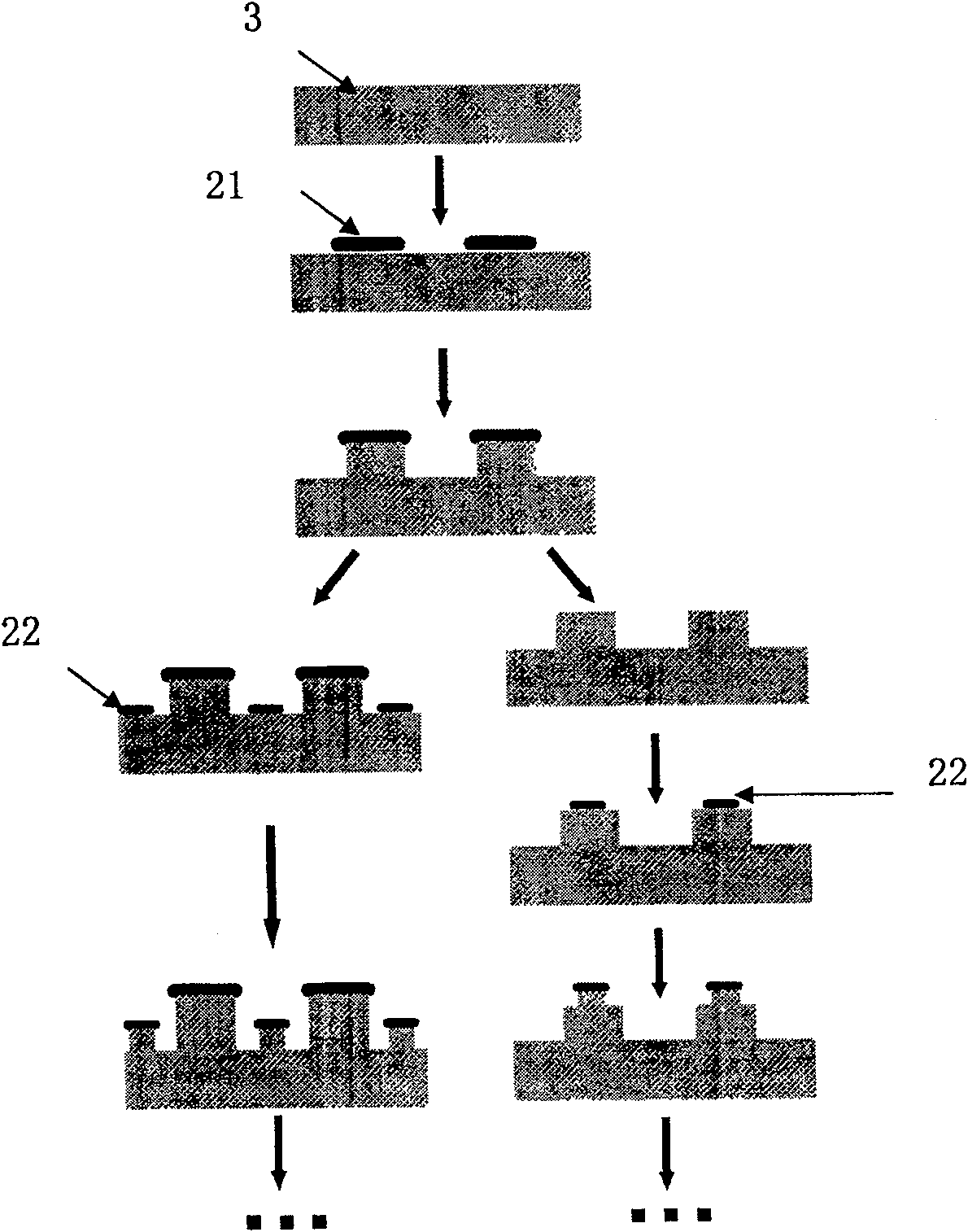

Method used

Image

Examples

Embodiment 1

[0035] (1) Cut the commercially purchased Si(110) silicon wafer (Beijing Institute of Nonferrous Metals) into small pieces of 1cm×1cm, making one side parallel to the Si{111} crystal plane; , ultrasonic cleaning with deionized water for 3 minutes; use Piranha solution [concentrated H 2 SO 4 :H 2 o 2 =7:3 (volume ratio)] Treat the Si sheet at 90°C for 10 minutes, take it out and clean it with deionized water; treat the cleaned Si sheet with 1% (mass percent concentration) HF aqueous solution for 1 minute, and deionized Rinse with water; use high-purity N 2 blow dry.

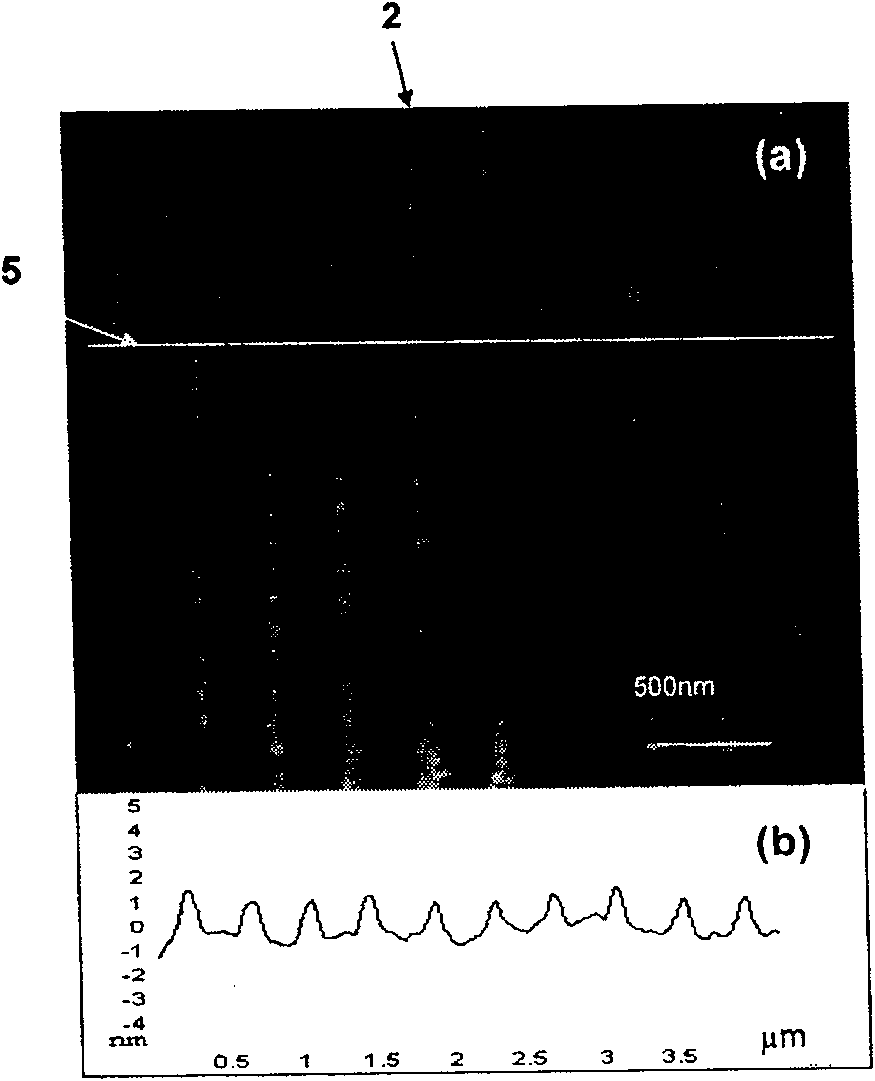

[0036] (2) Put the Si sheet processed in step (1) on the sample stage of a commercial scanning probe microscope (SPM, Dimension3100, Digital Instrument Corporation), and the relative humidity of the environment is 60%; select the area to be processed, and design the corresponding pattern (a set of parallel lines) and set the tip path; apply a bias voltage (tip bias-6V, tip movement speed 40 μm / s) between the ...

Embodiment 2

[0040] (1) Select commercially purchased Si(100) silicon wafers (Beijing Institute of Nonferrous Metals), and the rest of the treatment is the same as the step (1) of Example 1.

[0041] (2) Except for the following specific conditions, other operations are the same as step (2) of Example 1: the relative humidity of the environment is 60%; the pattern is designed as a group of squares; the needle tip bias is -6V, and the needle tip movement speed is 1 micron / second.

[0042] (3) Put the sample treated in step (2) into the prepared wet etching solution [20% KOH aqueous solution, 50°C], and the control time is 120s; quickly take it out and put it in deionized water, wash, blow Dry.

[0043] (4) Scanning and imaging the processed structure with a scanning probe microscope (SPM, Dimension3100) again. As a result, an inverted pyramid structure was obtained as shown in Fig. 4(b), the width of the top line was 79.0nm, the width of the bottom line was 176.2nm, with inclined side wall...

Embodiment 3

[0045] (1) with the step (1) of embodiment 2

[0046] (2) except the following specific conditions, all the other operations are with the step (2) of implementation example 1: 40% of the relative humidity of the environment; the designed pattern is a combined pattern (a group of parallel lines, a group of periods is a grid of 1 micron, a A group of square grids with a period of 500nm, a group of diamond-shaped grids with a side length of 1 micron); the tip bias voltage is -12V, and the tip movement speed is 10 microns / second.

[0047] (3) Put the sample treated in step (2) into the prepared wet etching solution [20% KOH aqueous solution, 50°C], and the control time is 30s; quickly take it out and put it in deionized water, wash, blow Dry.

[0048] (4) Scanning and imaging the processed structure with a scanning probe microscope (SPM, Dimension3100) again. The result is shown in Figure 4(c), and the following combined patterns are obtained: a group of parallel lines, a group ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com