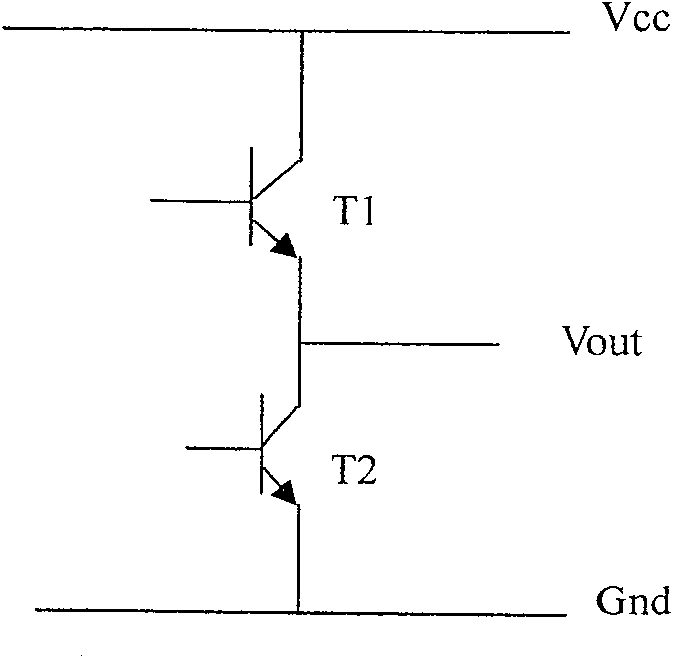

Technique for preparing bipolar type long-direction NPN tube using phosphorus-buried and deep phosphorus-buried technique

A bipolar, deep phosphorous technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high antimony buried layer resistance, affecting the output power of power amplifier circuits, and small antimony diffusion coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

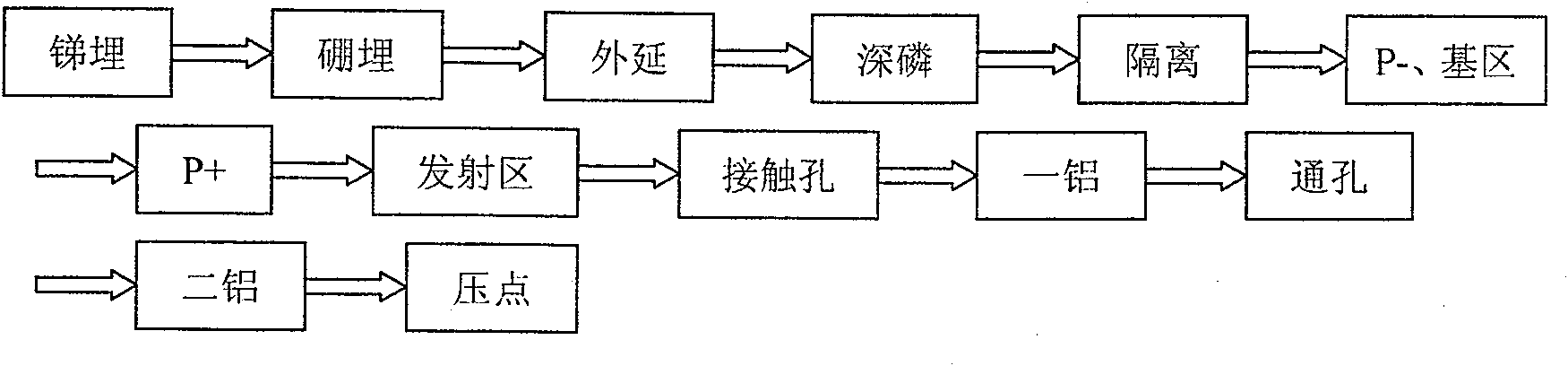

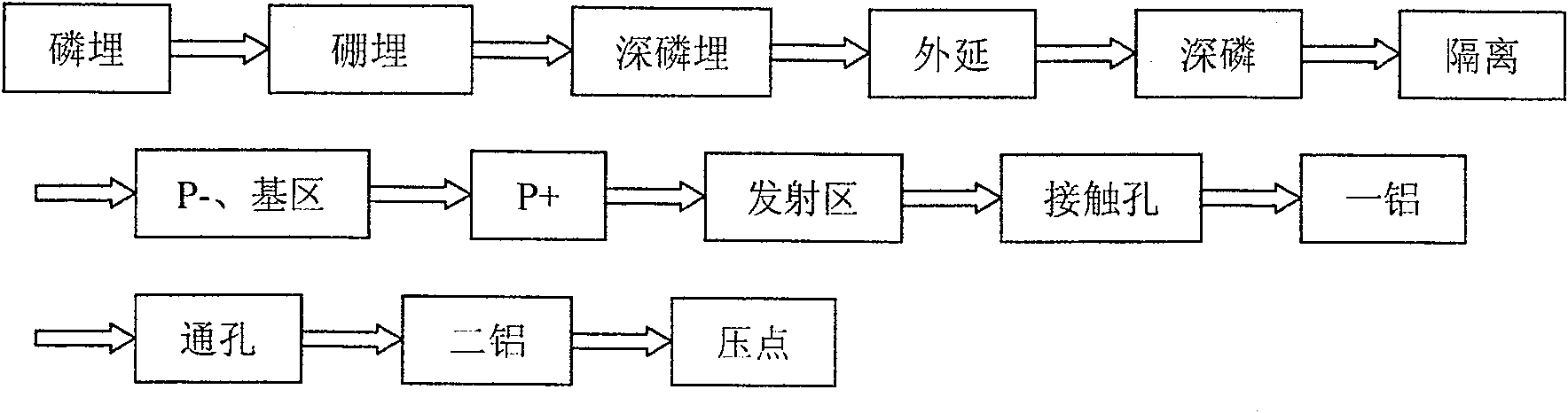

Method used

Image

Examples

specific Embodiment approach

[0058] The specific implementation of the bipolar process using phosphorus buried and deep phosphorus buried technology is as follows:

[0059] 1. Feeding: P type, crystal orientation ,

[0060] 2. Oxidation: Thickness

[0061] 3. Phosphorus buried photolithography and corrosion; engrave the vertical NPN tube N buried area window,

[0062] 4. Phosphorus buried implantation: the implantation energy is 80KeV, and the implantation dose is 1E15; the impurity is phosphorus, and the N-buried area of the NPN tube is injected with phosphorus,

[0063] 5. Phosphorus buried annealing: the annealing condition is 1200°C for 300 minutes N2+120 minutes O2,

[0064] 6. Boron buried photolithography and implantation: the implantation area is the isolation trench area, the implantation energy is 80KeV, the implantation dose is 5E14, and the impurity is boron.

[0065] 7. Deep phosphorus buried lithography and implantation: the implantation area is a deep phosphorus area, the implantatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com