Air knife and water-cooling block combined saw belt quenching cooler

A water-cooled, composite technology, applied in quenching devices, furnaces, heat treatment equipment, etc., can solve the problems of slow cooling speed of the tooth tip, small gas flow, large maintenance, etc., to achieve excellent hardness, strength and structure, cooling The effect of stable speed and improved hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

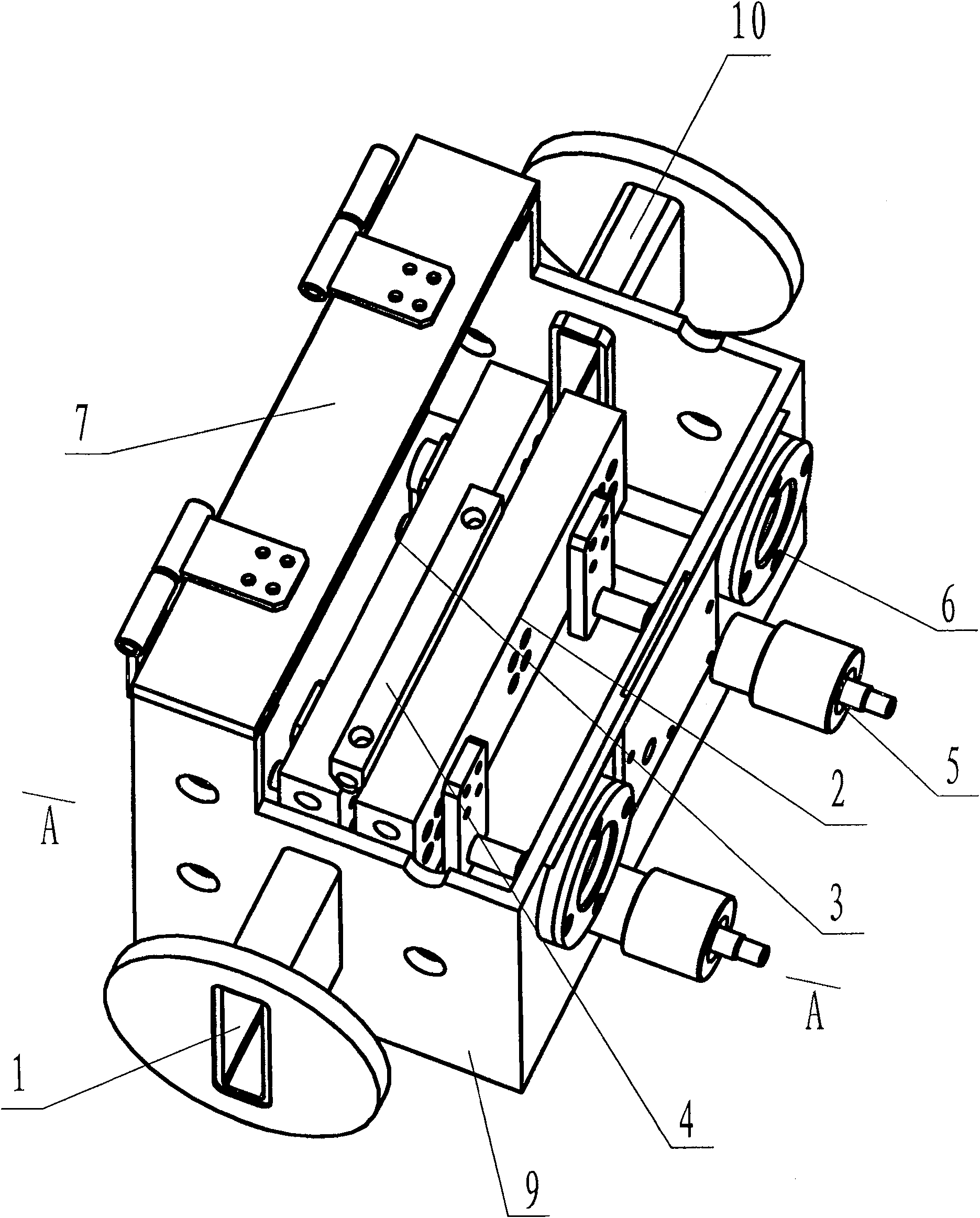

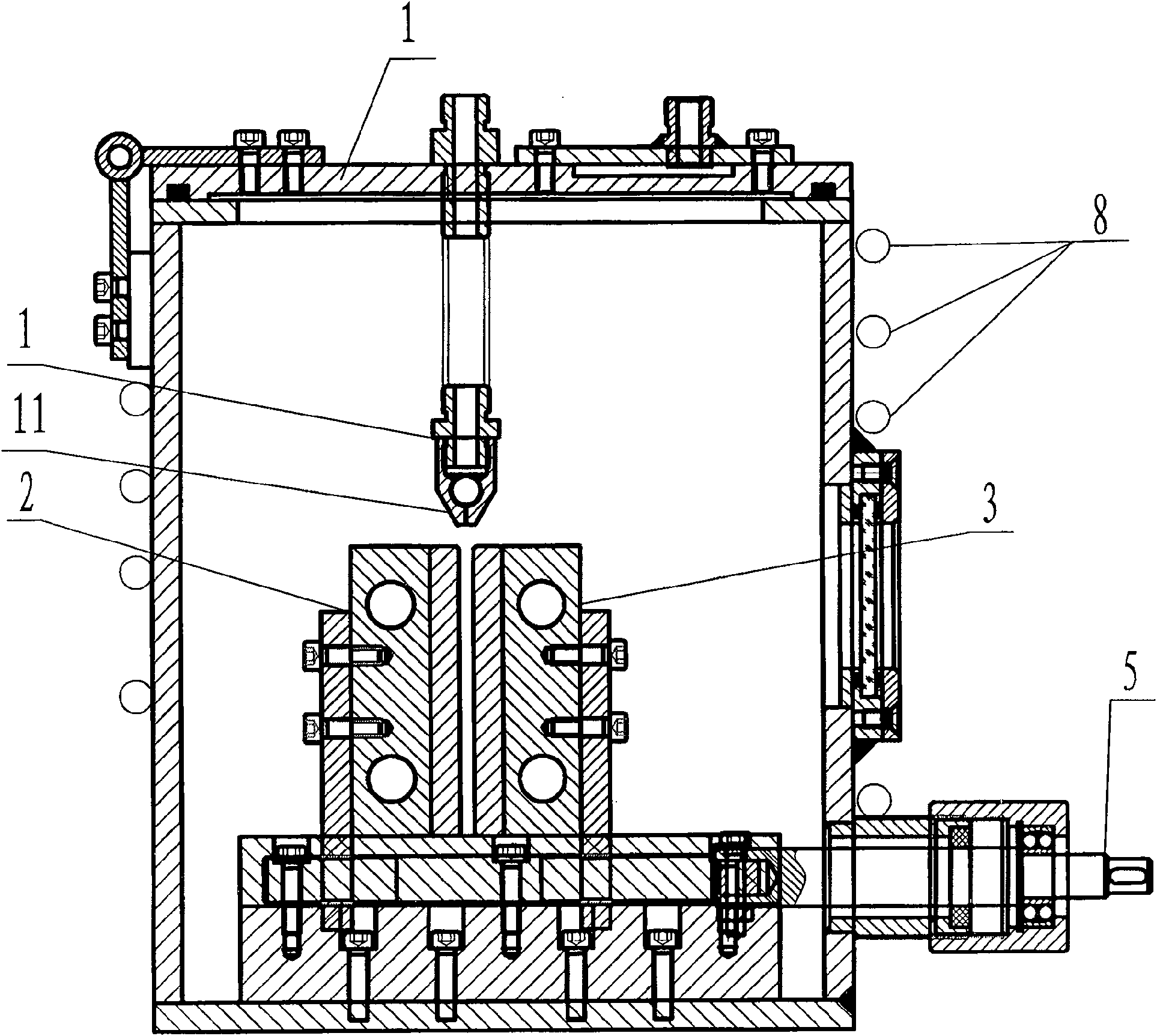

[0016] Such as Figures 1 to 2 As shown, the air knife and water cooling block composite saw band quenching cooler of the present invention has a closed box 9 with a box cover 7, and the two ends of the closed box 9 are respectively provided with corresponding saw band inlets 1 and saw band outlets. 10. Two parallel water cooling metal blocks 2, 3 are arranged in the closed box 9 between the saw band inlet 1 and the saw band outlet 10, and the two water cooling metal blocks 2, 3 There is a gap for the saw band to pass through; an air knife 4 is installed above the gap between the two water-cooled metal blocks 2, 3, and the bottom of the air knife 4 has a corresponding to the two water-cooled metal blocks 2 , a row of air nozzles 11 in the gap between 3 (see figure 2 ), the rear end of the air nozzle is communicated with the air inlet interface of the air knife through the air knife internal air passage; figure 2 ).

[0017] It is best to use high wear-resistant sealing ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com