High temperature resistant low speed bearing

A high-temperature-resistant, low-speed technology, applied in the field of bearings, can solve problems such as increased bearing wear, heat accumulation, and easy locking of bearings, and achieve the effects of saving production and maintenance costs, reducing wear and consumption, and preventing axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

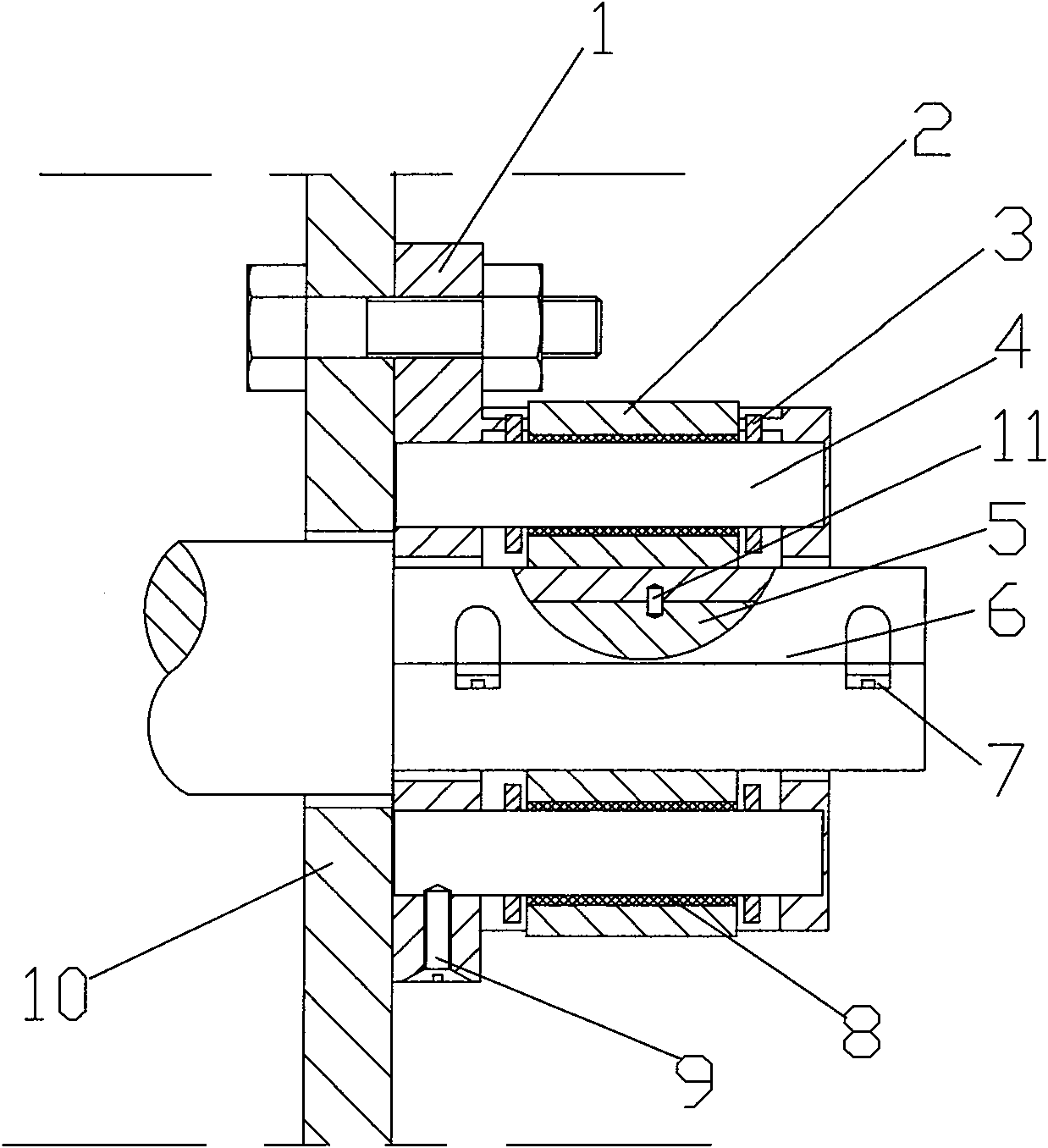

[0019] The accompanying drawing is a schematic structural view of the present invention, as shown in the figure: the high temperature resistant low-speed bearing of this embodiment includes a bracket-shaped bearing seat 1, and the base of the bracket-shaped bearing seat 1 is fixedly arranged on a non-rotating part 10 of a rotating machine , including six roller shafts 4 and rollers 2 sleeved on the roller shafts 4, metal plastic bushings 8 are fixed on the inner surface of the rollers 2, the radial clearance between the rollers 2 and the roller shafts 4 is 0.5mm, and the roller shafts 4 The retaining ring 3 is fixed at both ends of the roller 2, and the axial gap between the retaining ring 3 and the roller 2 is 1.5 mm; six roller shafts 4 are evenly distributed around the rotating shaft 5 in parallel with the rotating shaft 5, and the two ends of the roller shaft 4 are carried on the bracket Both ends of the bearing seat 1; the outer circle of the roller 2 and the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com