Road surface structure of felexiable fibre emulsifying asphalt stable material as base and construction method thereof

A technology of emulsified asphalt and flexible fiber, which is applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problem that the paving temperature is not lower than 145°C, the initial pressure temperature is not lower than 135°C, and the final pressure temperature is average. Not lower than 80 ℃, affecting the durability of asphalt stabilized aggregates, fatigue cracking at the bottom of the layer, etc., to achieve the effect of improving the internal structure composition, reducing reflective cracks on the road surface, and enhancing crack resistance and deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

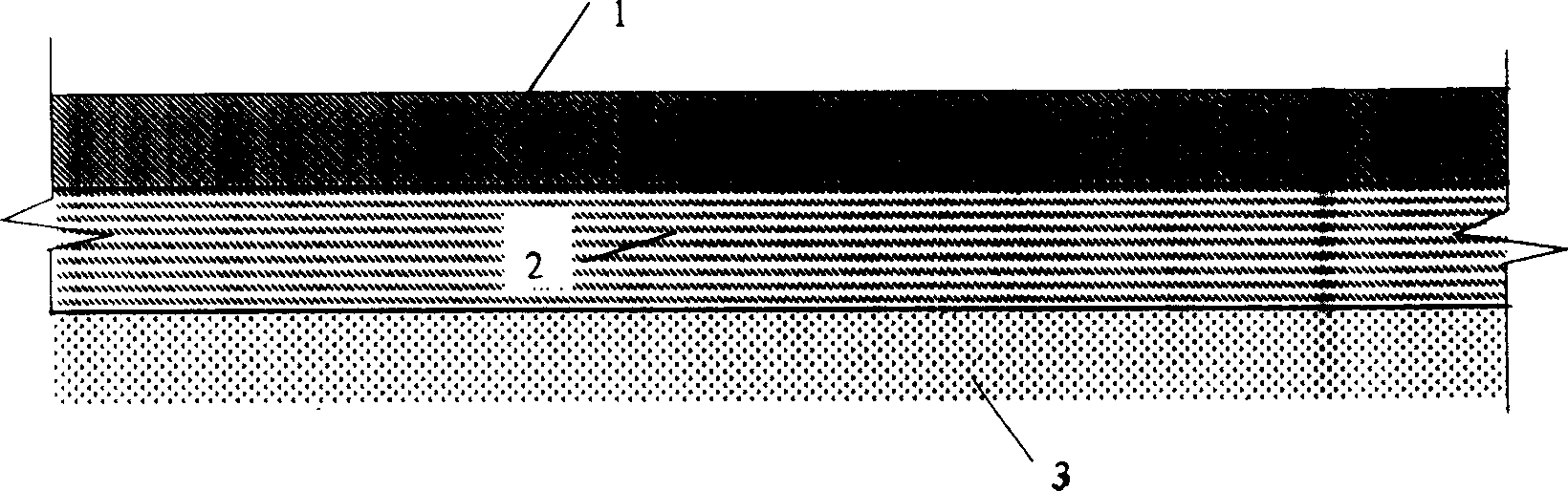

[0051] As shown in the accompanying drawing, pave flexible fiber-emulsified asphalt stabilized aggregate on the surface of the bottom layer 3, form a flexible fiber-emulsified asphalt-stabilized aggregate pavement base 2 through rolling, and then pave on the flexible fiber-emulsified asphalt-stabilized aggregate pavement base 2 Build the surface layer 1.

[0052] Concrete construction method of the present invention:

[0053] The ratio of a typical embodiment is (one cubic meter of flexible fiber emulsified asphalt stabilized aggregate): 1 kg of polypropylene monofilament fiber, 2100 kg of gravel with a maximum particle size of no more than 31.5 mm, 50 kg of stone powder, 60 kg of fly ash, cement 60kg, 0.85kg of anti-stripping agent, and 50kg of water were put into the mixer and mixed for 30s, then 150kg of cationic emulsified asphalt was added for wet mixing for about 30s until the flexible fiber and emulsified asphalt were evenly dispersed, and then the flexible fiber emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com