Prism, prism production method, optical pick-up and liquid crystal projector

A manufacturing method and prism technology, applied in prisms and other directions, can solve problems such as uneven thickness, inability to perform optical functions, inability to reduce stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

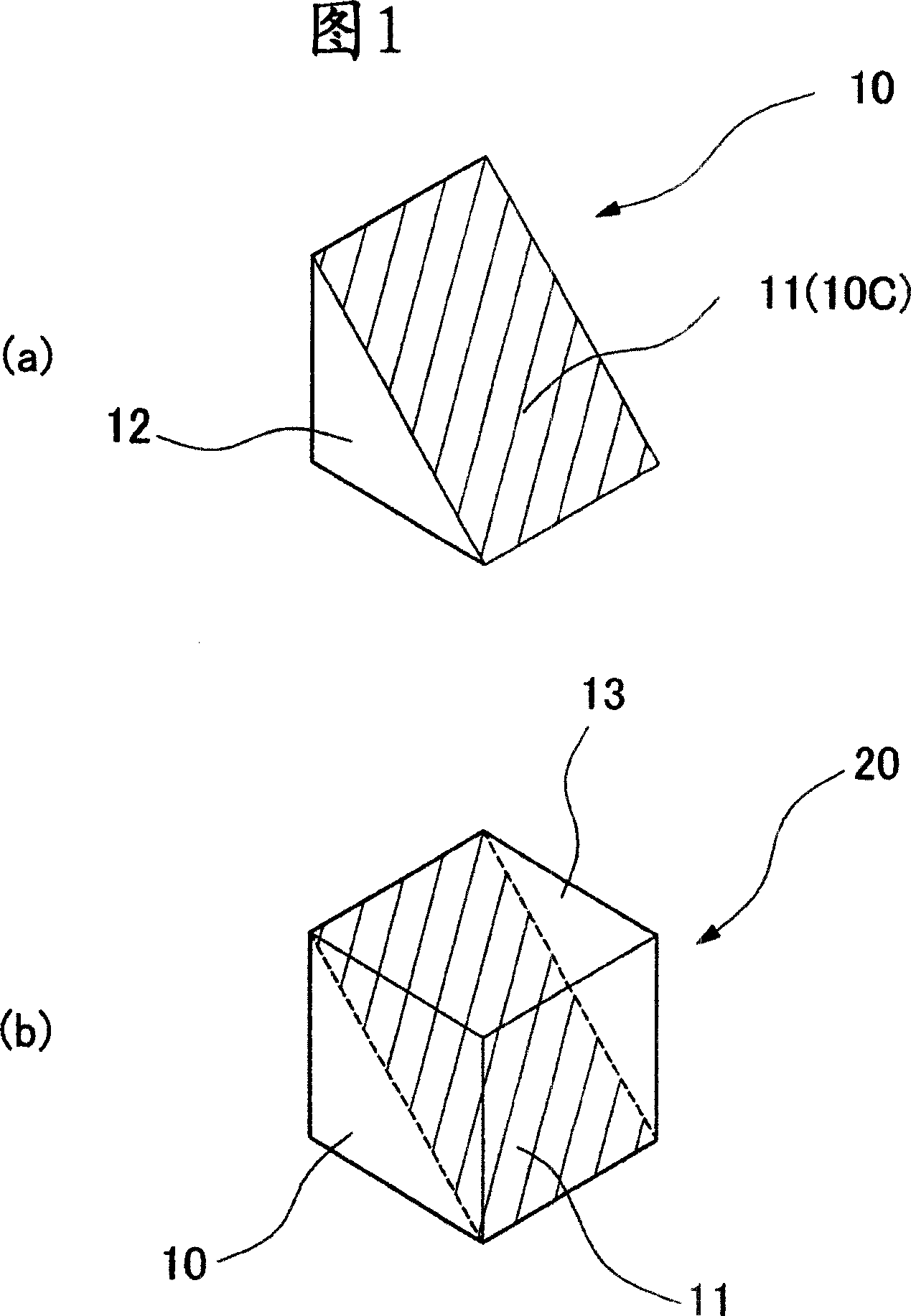

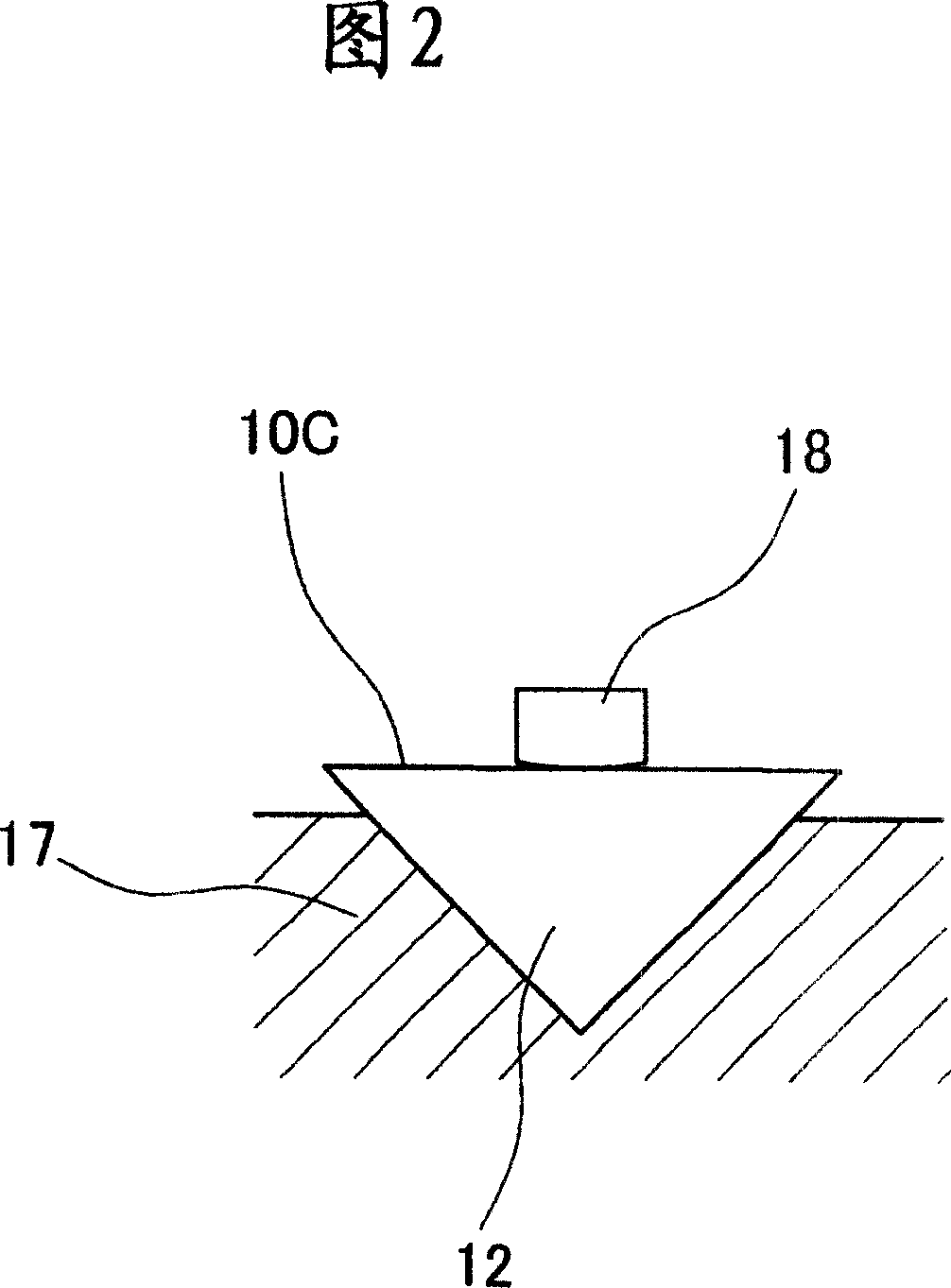

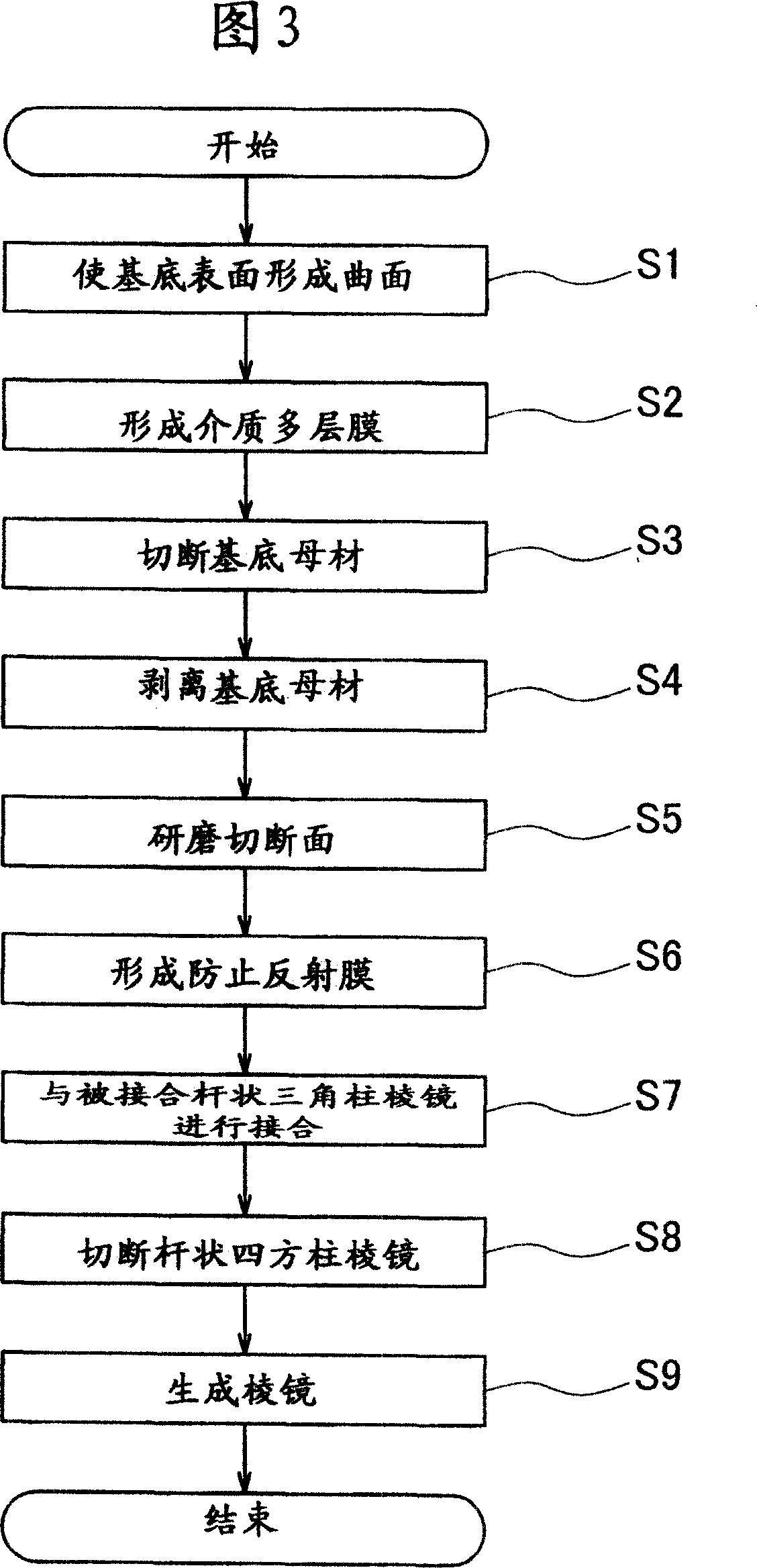

[0047] The present embodiment will be described below with reference to the flowchart in FIG. 3 . In this example, the final purpose is to manufacture the cubic square prism 25 (hereinafter simply referred to as "prism 25") of FIG. 7(b) in the above-mentioned embodiment. Furthermore, the prism 25 of this embodiment functions as a polarization beam splitter. Therefore, the dielectric multilayer film 11 formed on the prism 25 is a polarization separation film that uses the polarization direction of incident light to divide transmission and reflection. Of course, dichroic mirrors, reflective mirrors, etc. may be used instead of polarization beam splitters.

[0048] As mentioned above, the prism 25 functioning as a polarizing beam splitter needs to increase the number of layers of the dielectric multilayer film 11 functioning as a polarized light splitting film in order to be compatible with laser light having three wavelengths: CD, DVD, and large-capacity optical disc. Therefor...

no. 2 Embodiment

[0067] The second embodiment will be described below. In the above-mentioned first embodiment, in order to produce the rod-shaped triangular prism 60, the base base material 50 is cut from the surface opposite to the surface on which the dielectric multilayer film 11 is formed to form a zigzag shape. However, in the present embodiment, the rod-shaped triangular prism 60 is produced from the base base material 50 by a method different from that in the first embodiment.

[0068] As shown in FIG. 8(a), the large base base material 50 of the first embodiment is cut into a rectangular shape. In this way, many elongated rectangular base bodies 51 having a rectangular shape as shown in (b) of the same figure can be produced (rectangular shape cutting step). In the case of the present embodiment in which the finally produced prism 25 is a cube, the elongated rectangular base body 51 is formed as an elongated base body with a square cross section. Therefore, in the 2 ridgelines of th...

no. 3 Embodiment

[0071] An example of an optical pickup using the prism 25 used as a polarization beam splitter manufactured in the first embodiment or the second embodiment will be described below. In FIG. 9 , the optical pickup of this embodiment has structurally: a light source 101 , a polarization beam splitter 102 , a λ / 4 wavelength plate 103 , an objective lens 104 and a photodetector 105 . One of the laser beams of three wavelengths, CD, DVD, and large-capacity optical disc, is selectively oscillated from the light source 101 . The polarizing beam splitter 102 is the same as the prism 25 described in the first and second embodiments above. In this embodiment, it is used as a polarization beam splitter compatible with three wavelengths. Therefore, in the polarized beam splitter 102, a polarized light splitting film is formed which divides transmission and reflection using the polarization direction of incident light (same as the dielectric multilayer film 11 of the first and second embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com