Heat radiation insulation resin composition and printing circuit board using same

A technology of insulating resin and resin composition, which is applied in the direction of printed circuit parts, circuit substrate materials, circuits, etc., can solve the problems of lack of heat dissipation, heat dissipation of resin insulating layer, heat accumulation on the substrate, etc., and achieve suppression Effects of sedimentation and aggregation, excellent storage stability, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] Next, the present invention will be described in detail by giving examples and comparative examples of the present invention. Of course, the present invention is not limited by the following examples. In addition, the following "parts" and "%" mean "parts by mass" and "% by mass" unless otherwise specified.

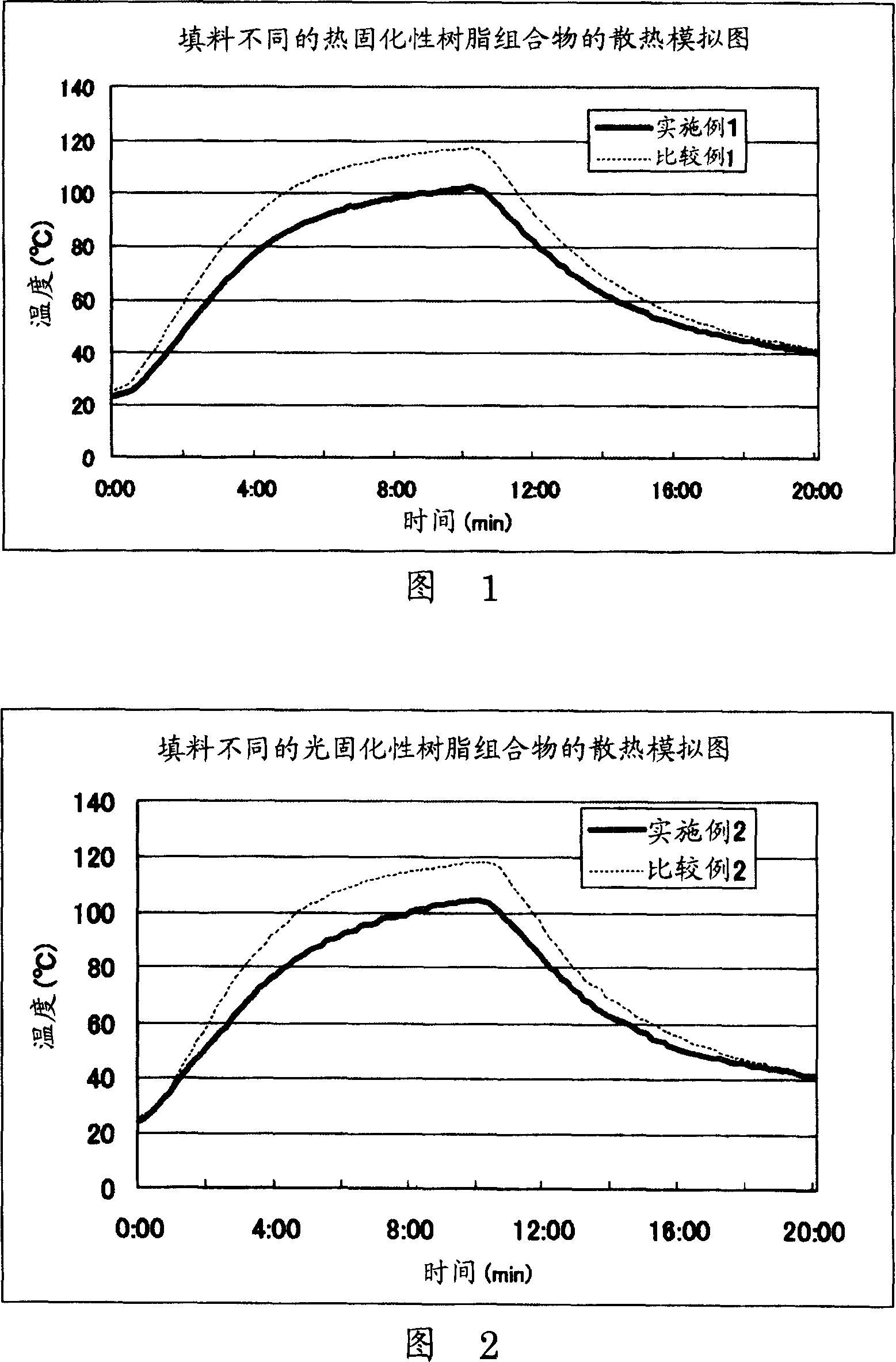

[0058] The mixed components of Examples 1 and 2 and Comparative Examples 1 and 2 shown in Table 1 below were kneaded by a 3-roll mill to obtain curable resin compositions. The evaluation results of the storage stability of the obtained curable resin composition are shown in Table 2, the characteristic evaluation results are shown in Table 3, and the temperature simulation results are shown in FIGS. 1 and 2 .

[0059] Table 1

[0060] Example 1

Example 2

Comparative example 1

Comparative example 2

Spherical alumina (A-1-1) *1

24

24

-

-

Spherical alumina (A-1-2) *2

96

96

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com