Light bioreactor

A technology of photobioreactor and bioreactor container, which is applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc. It can solve the problem of low microalgae culture density and light source utilization. Low efficiency, large shear damage and other problems, to achieve the effect of low price, gas exchange aseptic culture, and small shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

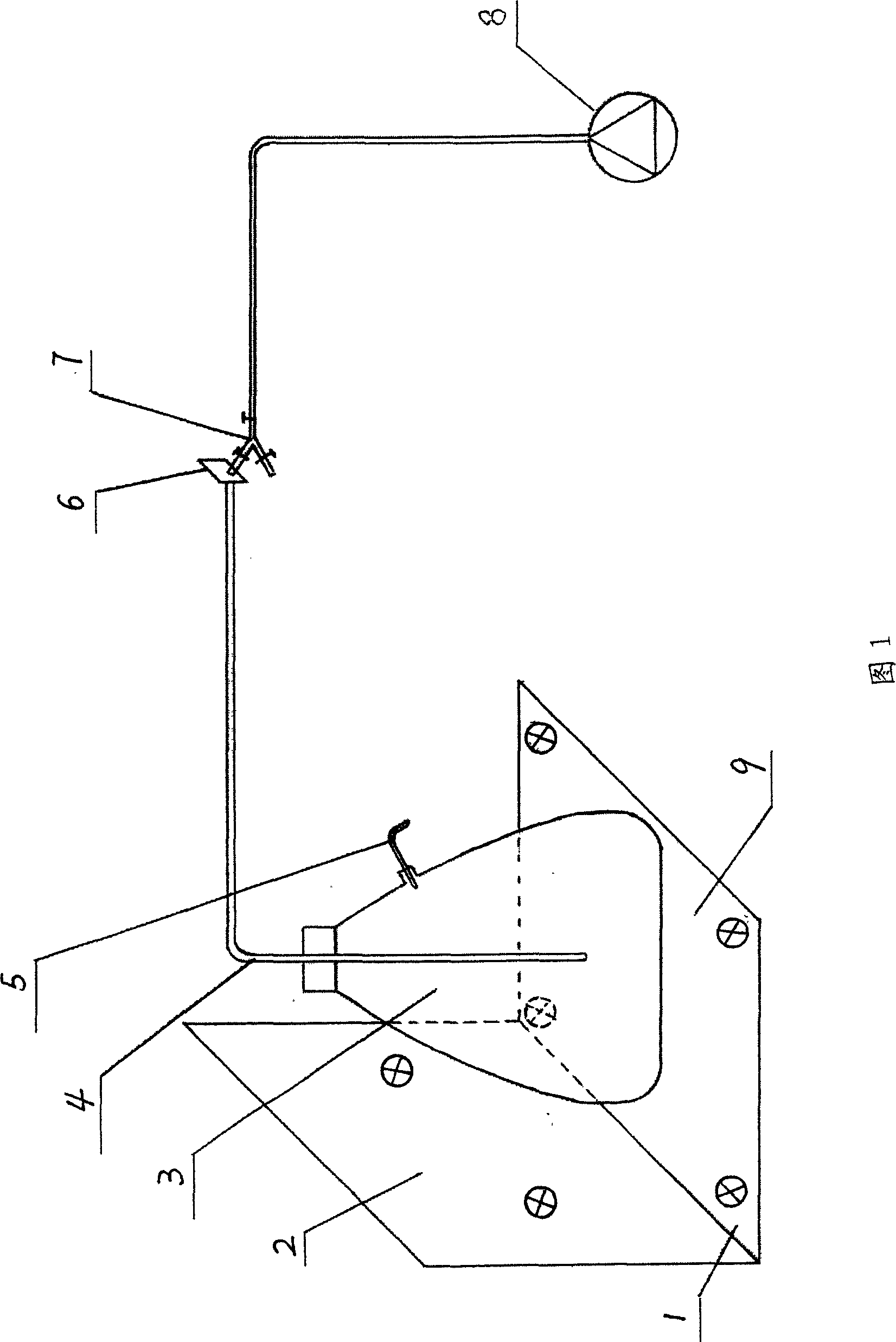

[0018] Fig. 1 is the structural representation of photobioreactor of the present invention, comprises base 9, transparent bioreactor 3, light source 1, air filter 6, three-way regulating valve 7 and air compressor 8, and transparent bioreactor is housed on the base 3. The ventilation port at the upper end of the transparent bioreactor is sealed with the outside world and equipped with a ventilation tube. 4. The distance between the lower port of the ventilation tube and the bottom of the transparent bioreactor is 3-5 cm, so that the sterile air that passes through has a better Stirring action. The ventilation pipe 4 is connected with the air filter 6, the three-way regulating valve 7 and the air compressor 8 in turn. When connected, the two ports of the three-way regulating valve are respectively connected with the air compressor and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com