Manual type device for sampling quantitative gas

A gas quantification and sampling device technology, applied in the preparation of test samples, analytical materials, instruments, etc., can solve the problems of inaccurate quantification, systematic errors, affecting detection accuracy, etc., to achieve simple operation, accurate quantification, and improved detection. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

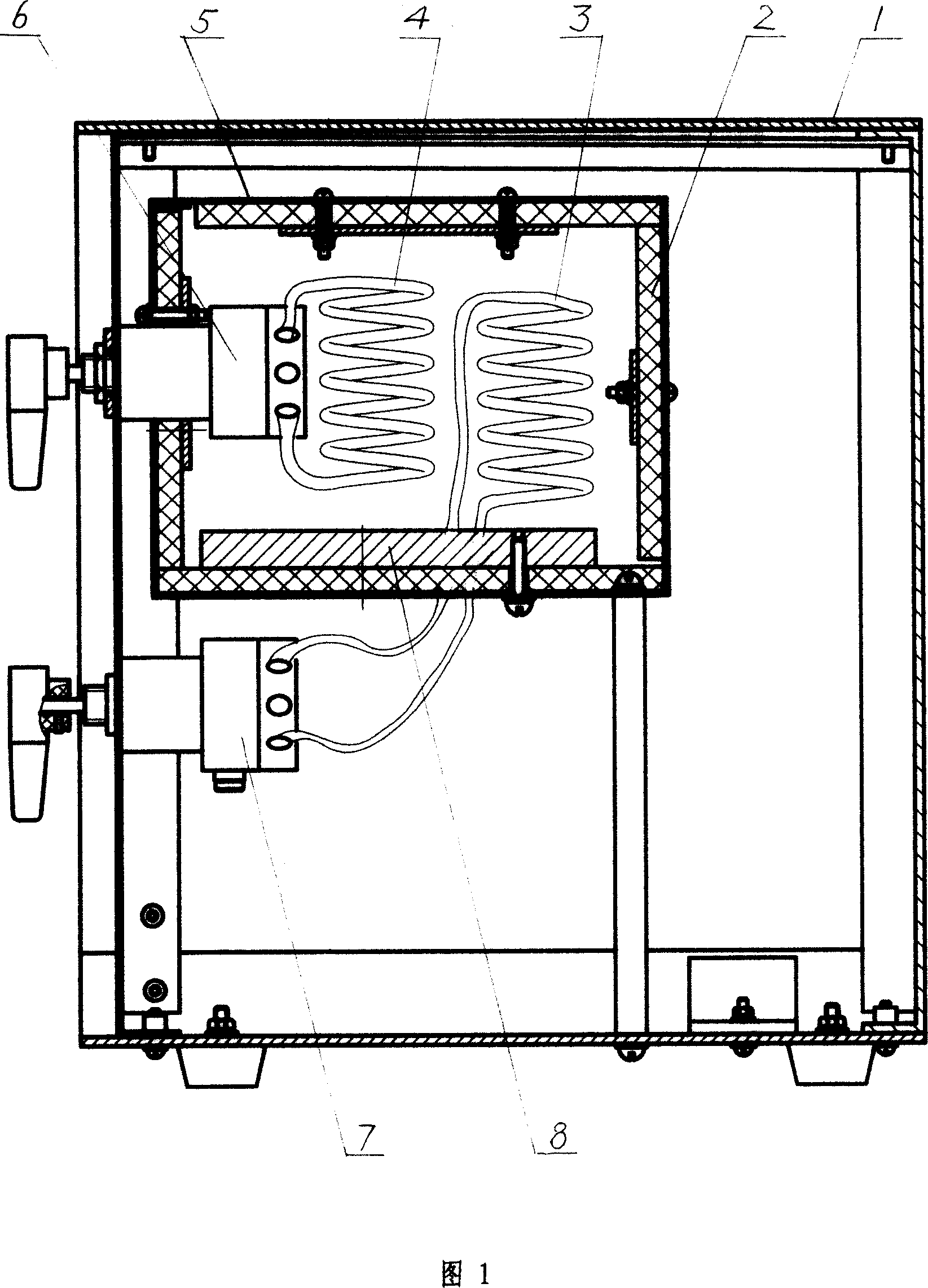

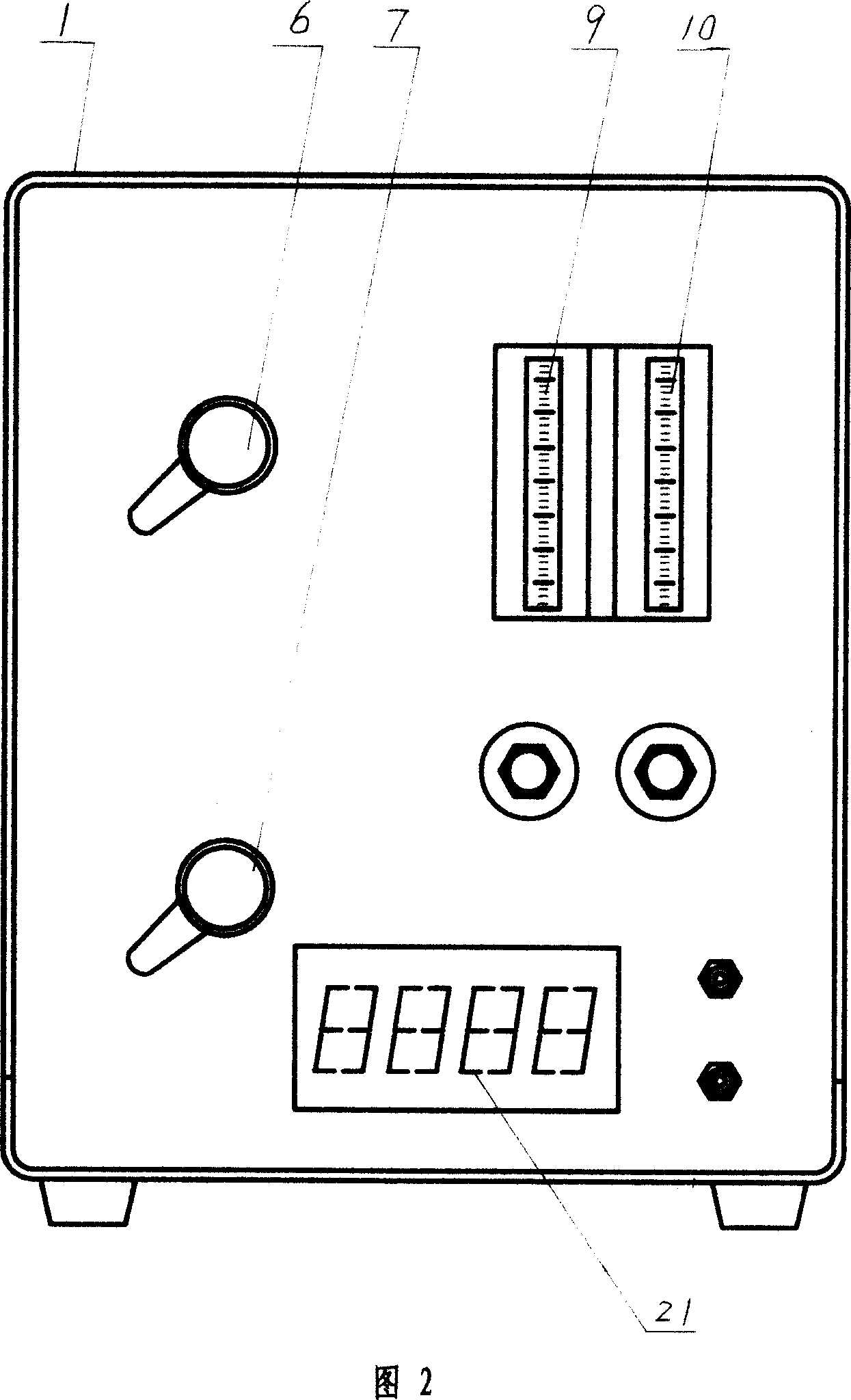

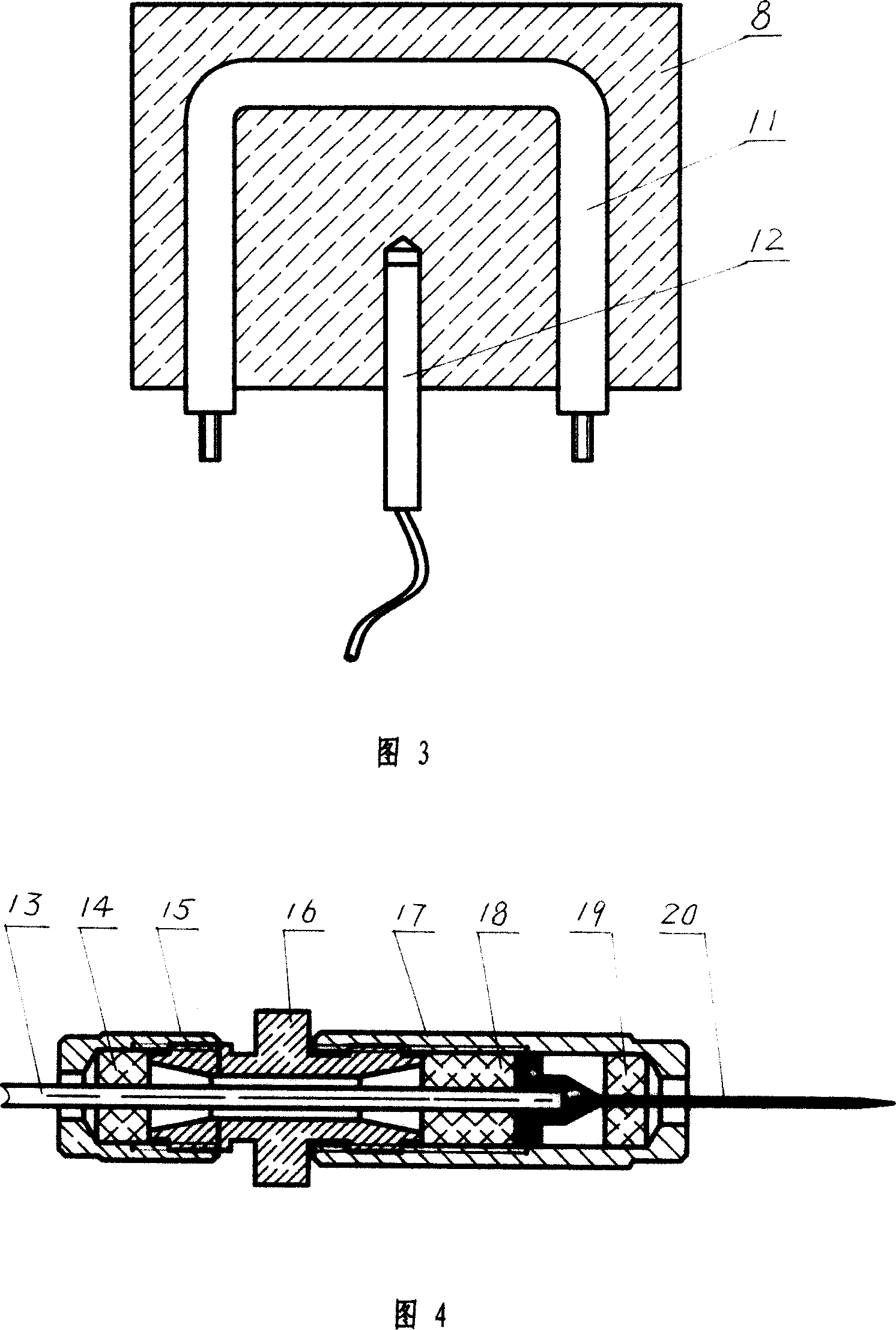

[0012] Referring to the accompanying drawings, the thermostatic chamber 5 is fixed inside the chassis 1. There is a heat dissipation plate 8 at the bottom of the inner cavity of the thermostatic chamber, and heat preservation panels 2 are provided on the four walls. The heat dissipation plate is embedded with an electric heating core 11 and is equipped with a temperature sensor 12. The panel of the chassis 1 Two-position six-way valves 6 and 7 and needle valves 9 and 10 are mounted on the top. Two quantitative tubes are arranged in the thermostatic chamber, wherein the quantitative tube 3 has a volume of 10ml, and its two ends are connected with the two ports of the six-way valve 7, and the volume of the quantitative tube 4 is 1ml, and its two ends are connected with the two ports of the six-way valve 6. The other ports of the six-way valve are respectively connected with the inlet pipes of sample gas A and B, the sampling needle, the needle valve and the exhaust pipe of excess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com