System for controlling procedure for warming - up wrapped welded tube with zinc coated, and plastic painted double layer, and control method

A technology of process control system and double-layer rolled welded pipe, which is applied in the general control system, control/regulation system, sequence/logic controller program control, etc., and can solve the problems of high maintenance cost, difficulty in popularization and application, and high price , to achieve the effect of high control precision, simple control system structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

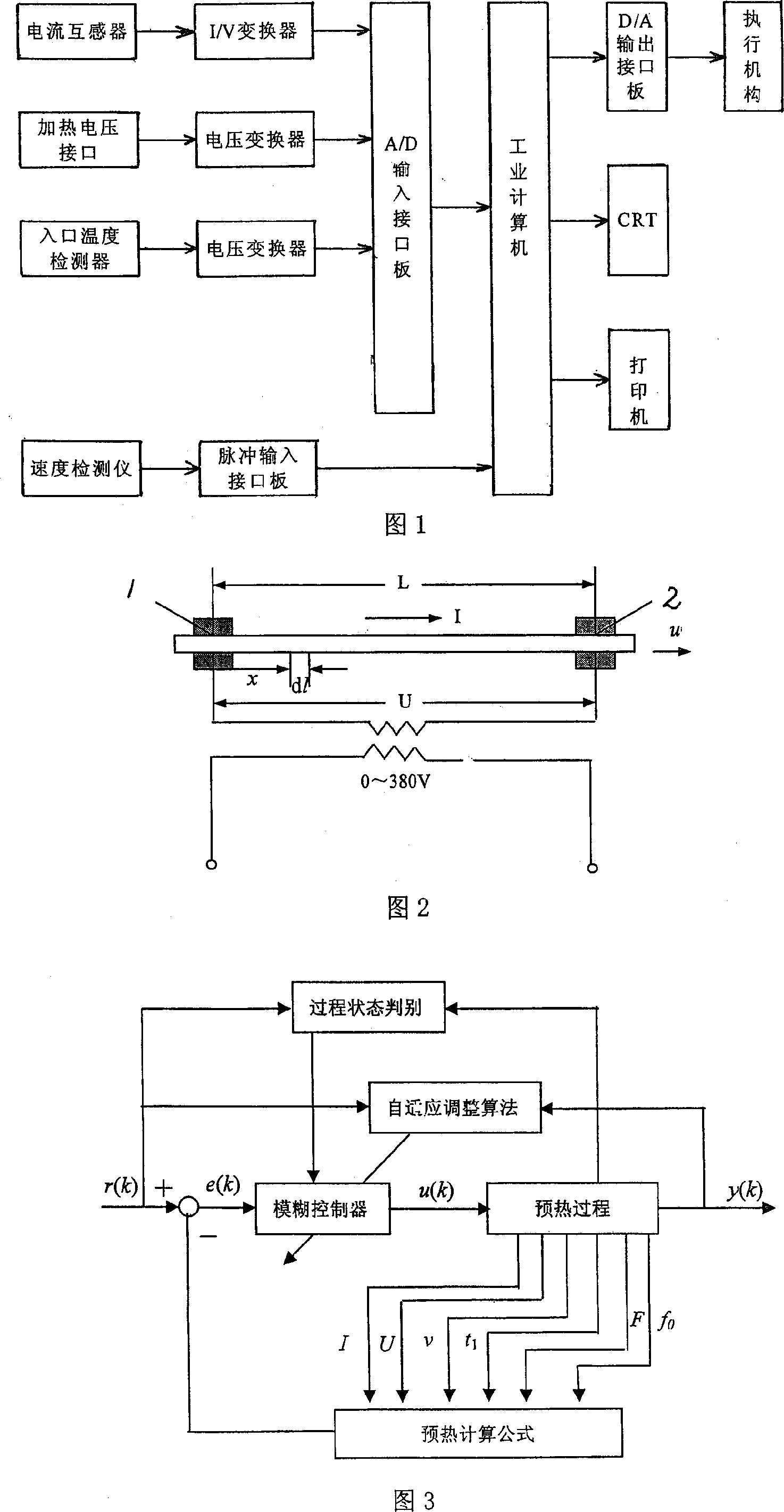

[0069] The embodiment of the control system of the present invention is shown in Fig. 1, and it is by the current transformer of measuring heating current, I / V converter, heating voltage interface, inlet temperature detector, voltage converter, the speed detector of measuring tube speed, pulse Composed of input interface board, A / D input interface board, industrial computer and its peripheral equipment, D / A output interface board, and actuator; the output end of the current transformer is connected to the input of the A / D input interface board through the I / V converter terminal, the heating voltage interface and the output terminal of the inlet temperature detector are respectively connected to the input terminal of the A / D input interface board through the voltage converter, the output terminal of the speed detector is connected to the input terminal of the industrial computer through the pulse input interface board, and the A / D The input interface board is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com