Module and system for solar electricity generation

A solar and battery technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of inability to configure modules, difficult setting operations, crystal loss, etc., to achieve the effects of reducing losses, easy setting operations, and improving the module configuration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

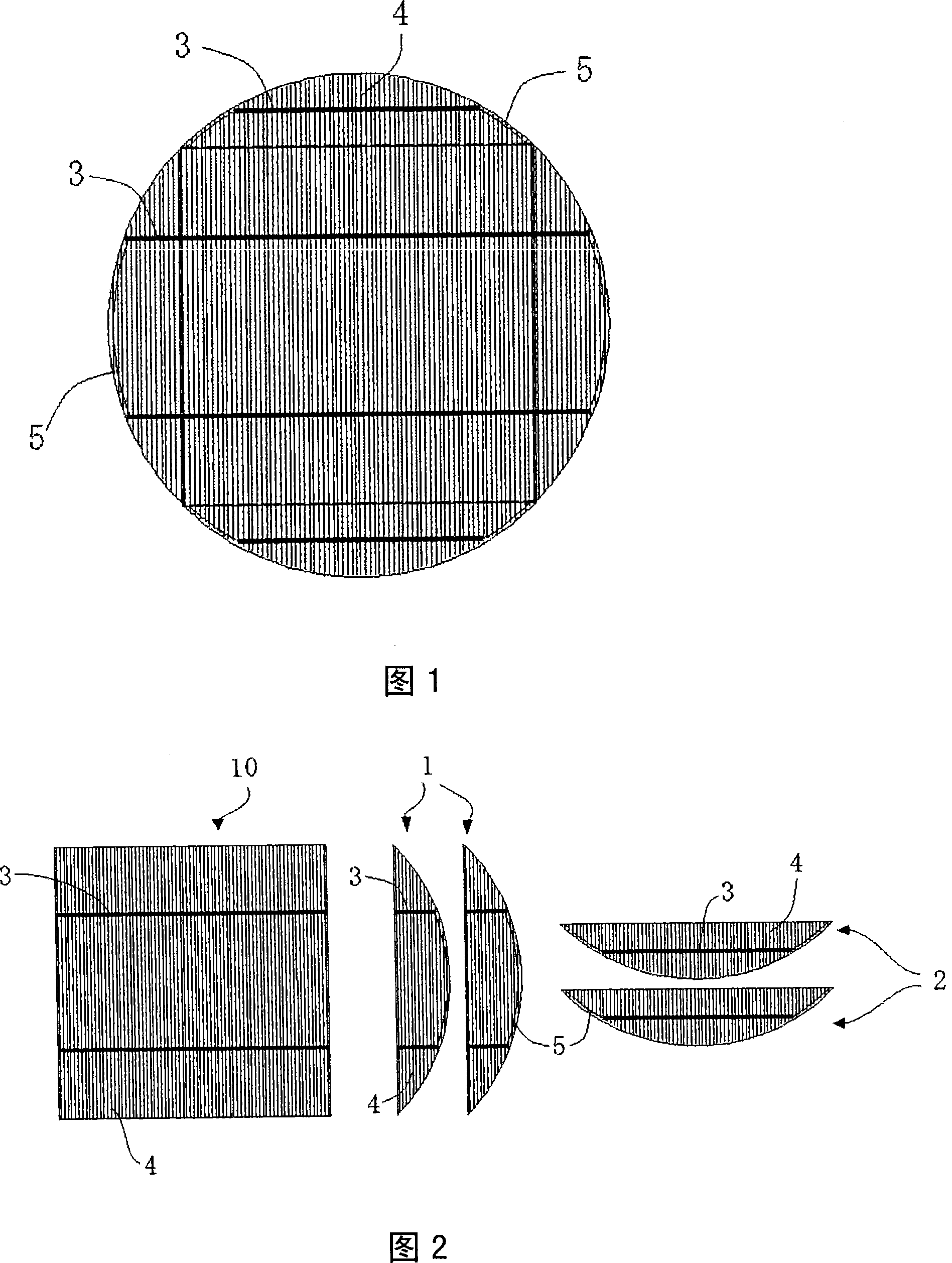

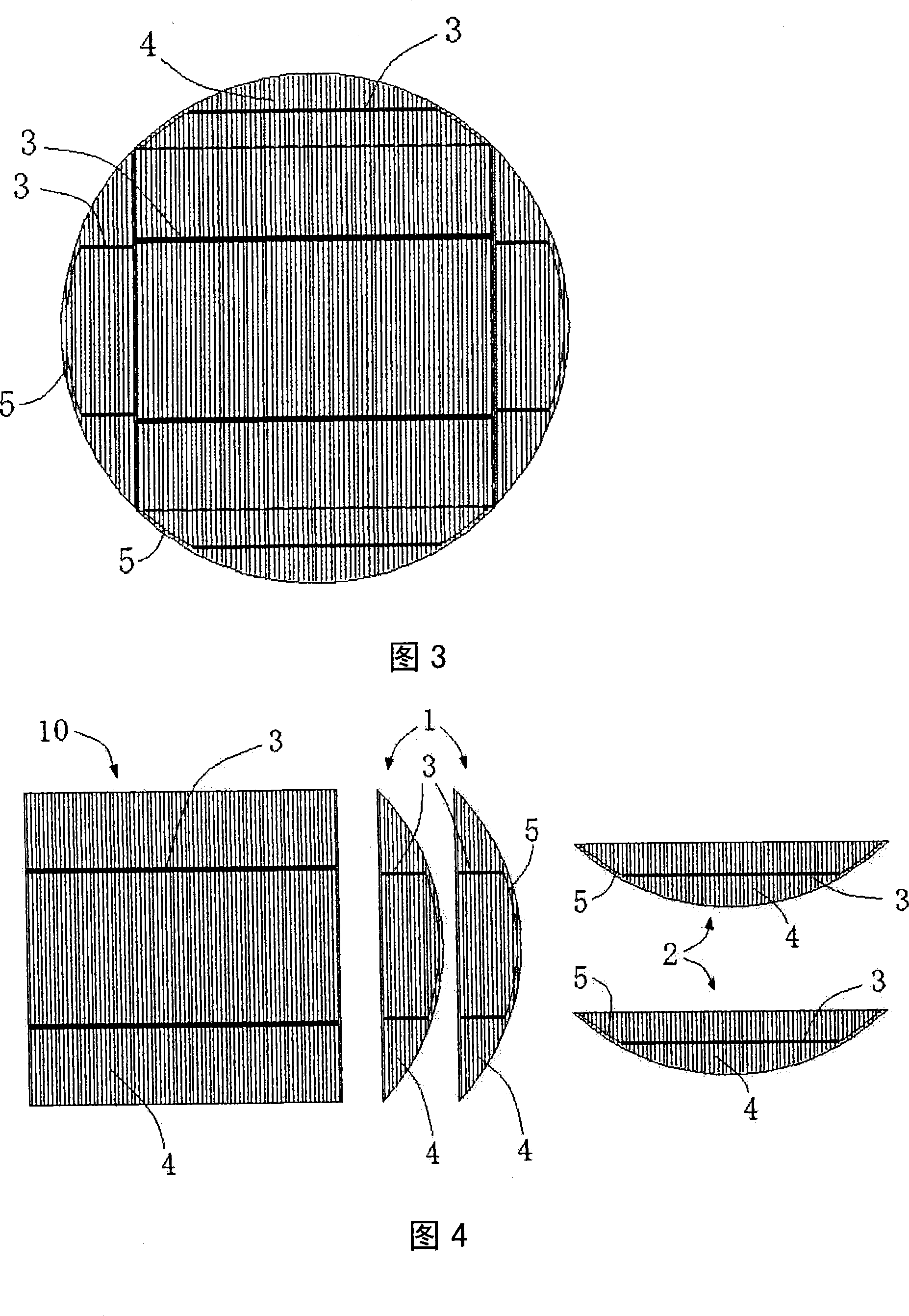

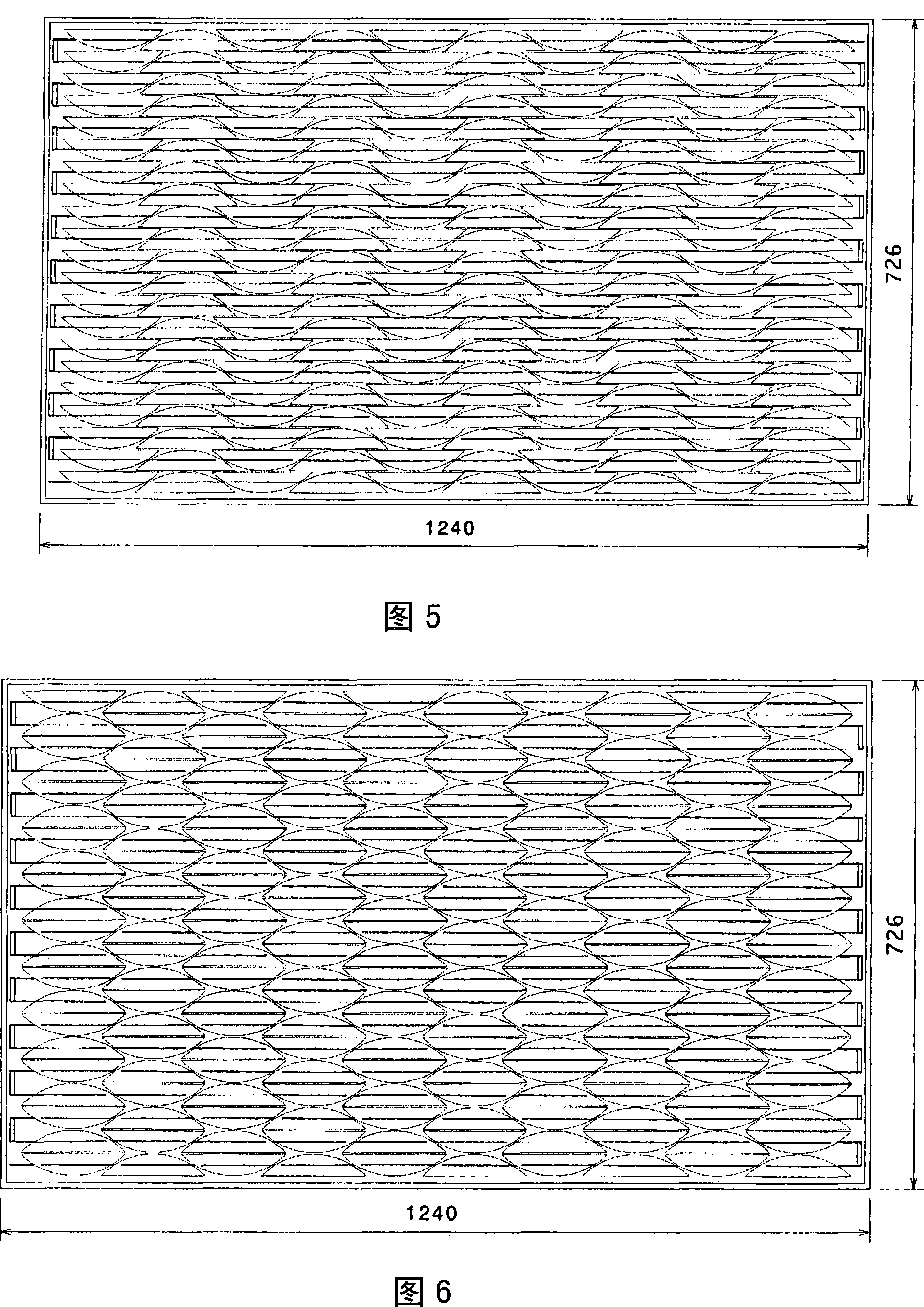

[0042] Hereinafter, the present invention will be described in detail with reference to the drawings as appropriate.

[0043] A first aspect of the present invention relates to a module for photovoltaic power generation, which is constituted by congruent arcuate cells.

[0044] A second aspect of the present invention relates to a photovoltaic power generation system comprising the above-mentioned module and an inverter.

[0045] The module for solar power generation is manufactured through a process of manufacturing a single crystal wafer as a substrate, a process of manufacturing cells (cells) for solar power generation, and a process of arranging the cells to form a module. Therefore, the following steps will be described in order of these steps, and the structure of the module will be described.

[0046] A brief description will be given of the single crystal wafer serving as the substrate. A silicon single crystal wafer is used as a wafer for photovoltaic power generatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com