Dual-fuel hot compression engine

An engine and thermal compression technology, which is applied in the direction of combustion engines, internal combustion piston engines, machines/engines, etc., can solve the problems of difficult starting of diesel engines, large compression ratio, high compression energy consumption, etc., to improve the mixing effect, reduce the compression ratio, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

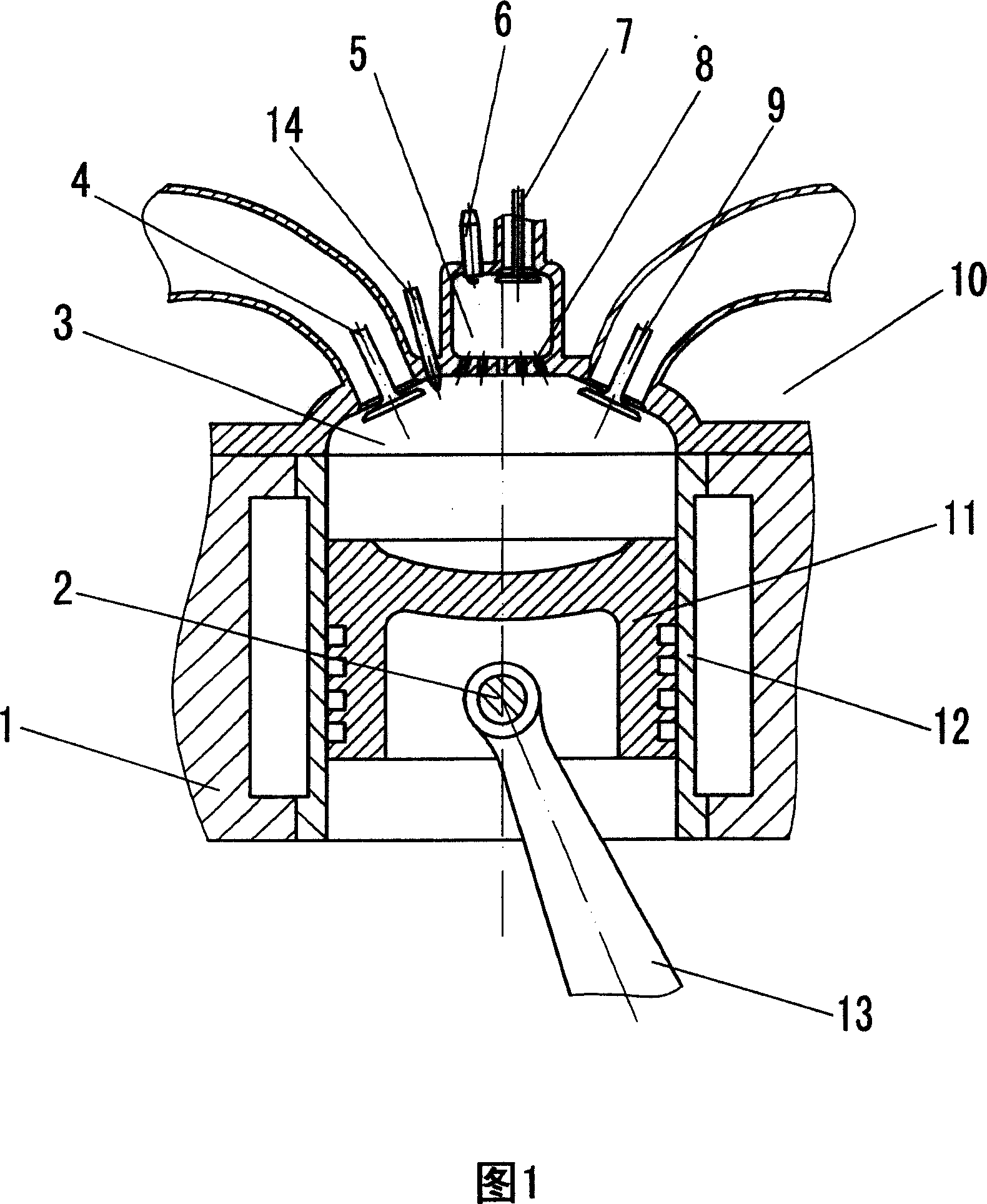

[0013] Figure number

[0014] 1. Engine casing 2. Piston pin 3. Diesel main combustion chamber

[0015] 4. Diesel intake valve 5. Gasoline secondary combustion chamber 6. Spark plug

[0016] 7. Gasoline intake valve 8. Gasoline combustion chamber nozzle 9. Diesel exhaust valve

[0017] 10. Engine cylinder head 11. Piston 12. Piston cylinder

[0018] 13. Connecting rod 14. Diesel injector

[0019] Please refer to Fig. 1, the present invention is a kind of dual-fuel thermal compression engine, and fuel is example with gasoline, diesel oil, and it has the piston 11 that is contained in the piston cylinder 12, and this piston is hinged connecting rod 13 with piston pin 2, and piston cylinder top There is an engine cylinder head, the upper part of the piston 11 is a diesel main combustion chamber 3, the top of the diesel main combustion chamber 3 is provided with a gasoline auxiliary combustion chamber 5, and the gasoline auxiliary combustion chamber 5 has a plurality of nozzles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com