Water energy-storage system with multi flume tanks and using method thereof

一种贮水槽、水蓄能的技术,应用在水蓄能系统,多贮水槽水蓄能系统领域,能够解决浪费贮存空间、降低蓄能效率、成本增加等问题,达到分层发生紊乱的机会减小、充能或释能同步、蓄能效率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

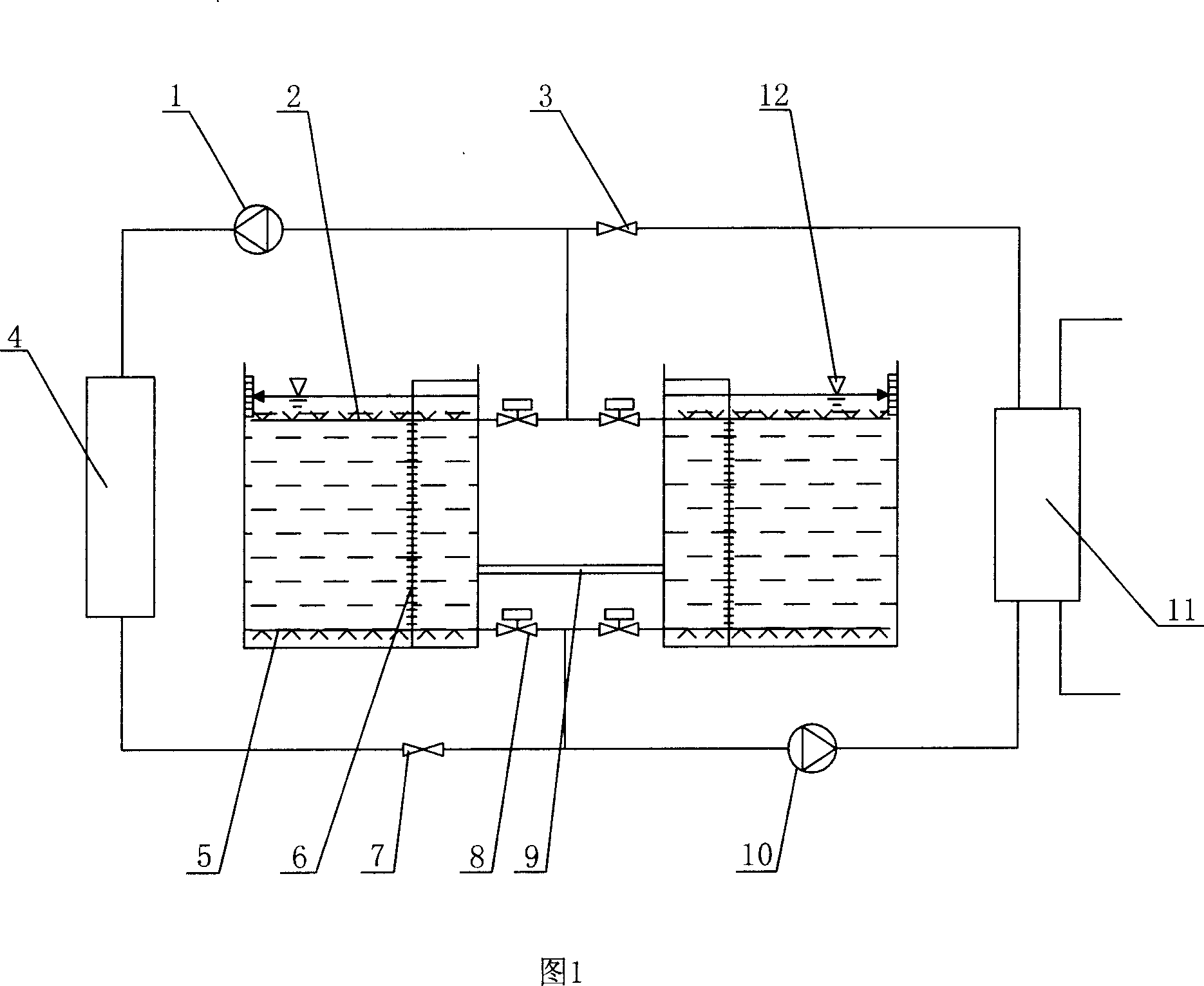

[0029] The embodiment shown in Figure 1, the water cold storage air-conditioning system has two water storage tanks, and the upper water distributor 2, the lower water distributor 5, the water level sensor 12 and the temperature sensor 6 are respectively arranged in the two water storage tanks, and the temperature sensor 6 There are a plurality of them, which are evenly distributed in each water layer of the water storage tank from top to bottom. The upper water distributors 2 of the two water storage tanks are connected in parallel and divided into two circuits, one of which is connected to the chiller 4 and the other is connected to the heat exchanger 11; the lower water distributors 5 of the two water storage tanks are connected in parallel and then divided into two circuits, one of which is connected to the chiller 4. The other road is connected to the heat exchanger 11; the water inlet and outlet pipes of the chiller 4 are respectively provided with a charge cooling pump 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com